Rolled lubricating process of rolling band-steel

A process method and roll-type technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems affecting the surface quality of strip steel, poor uniformity of lubricating oil, and affecting the stability of rolling steel, so as to reduce surface defects of strip steel, Avoid surface rolling and sintering, and enhance roll protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

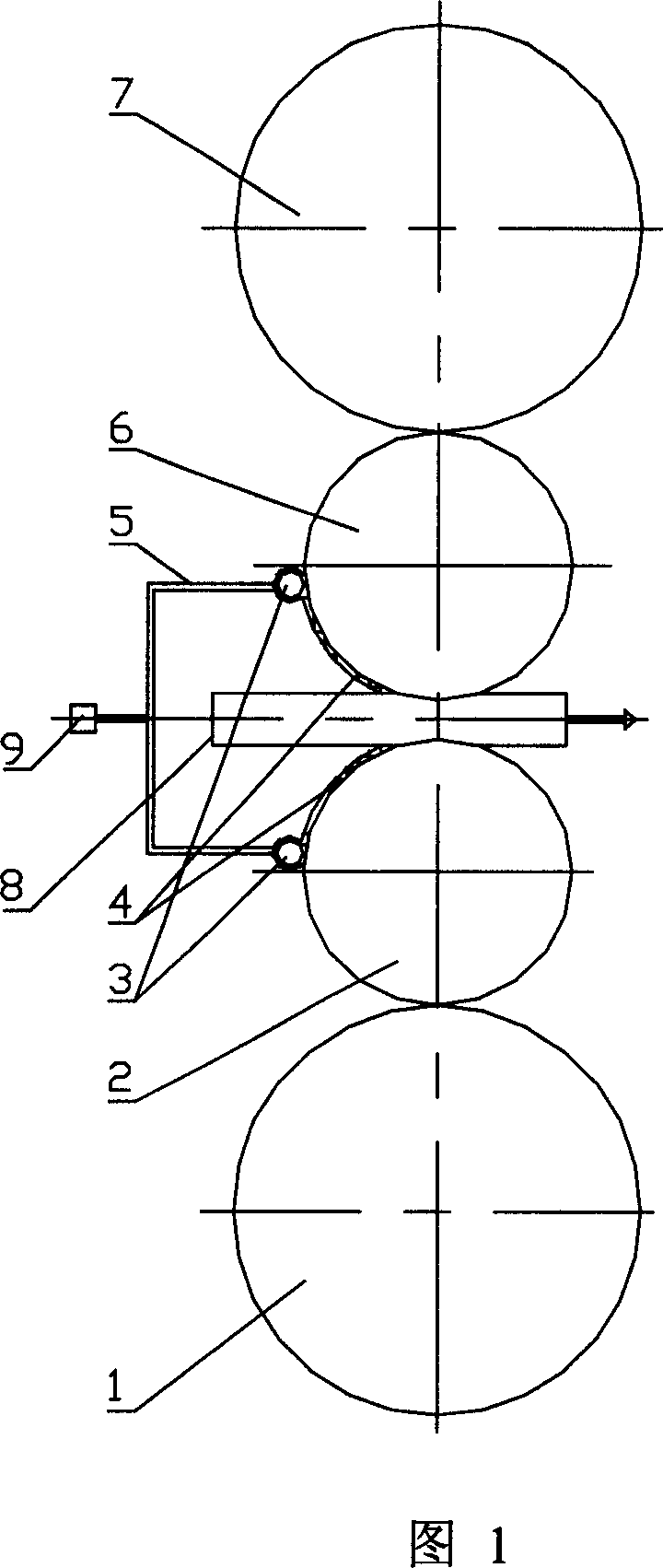

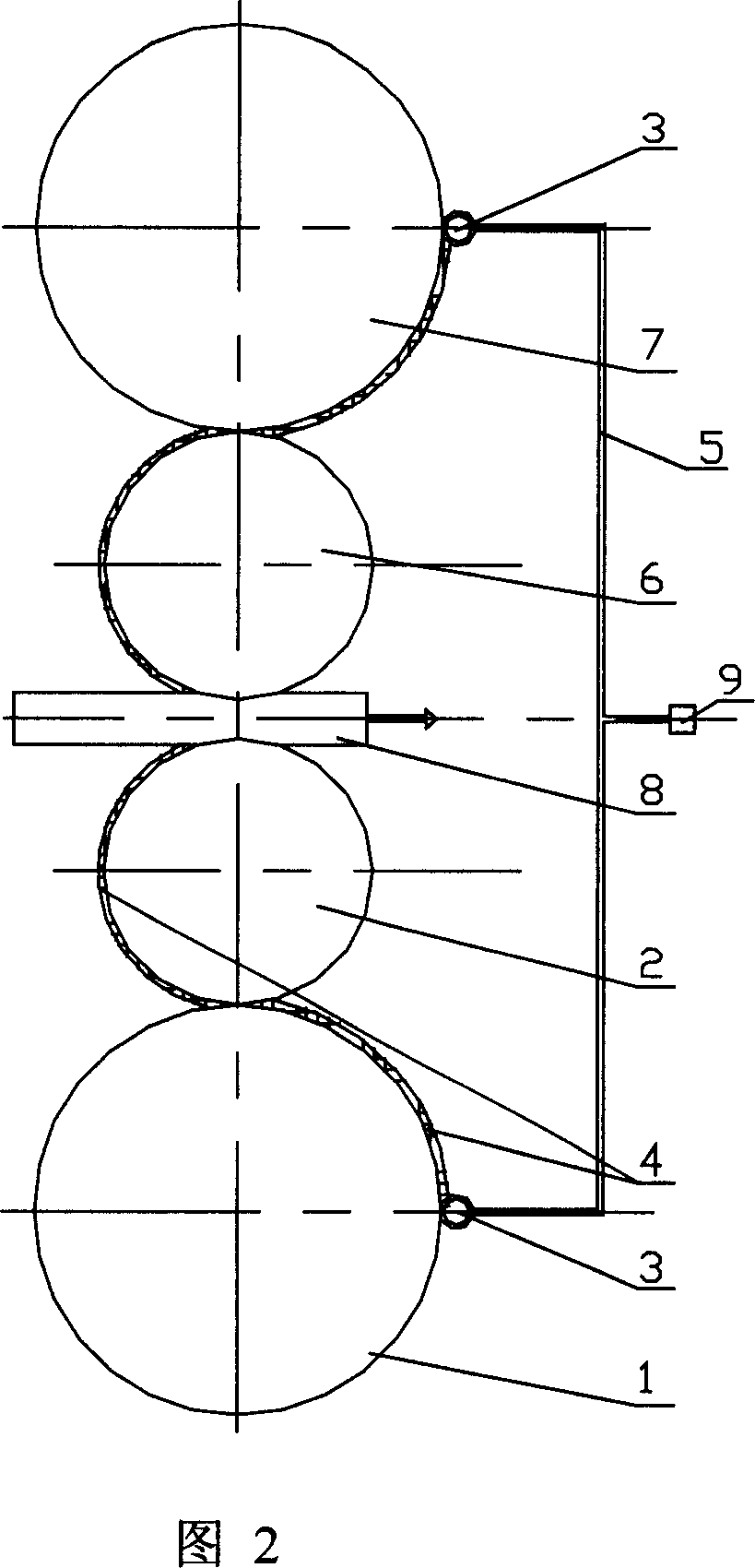

[0021] Referring to Fig. 1, Fig. 2 and Fig. 3, a rolling lubricating process for strip steel rolling is that the rolling lubricating oil 9 is transported to the oiling roller 3 through the oil pipeline 5, and the oiling roller 3 is pressed with a certain pressure. Rolling oil 9 is applied to the surface of the roll to form an oil film 4 on the roll and passively rotates with the roll. The thickness of the oil film 4 is adjusted by the pressure of the oil-applied roll 3 on the roll and the amount of rolling oil supplied. The rolls include an upper work roll 6 , a lower work roll 2 , or an upper back-up roll 7 and a lower back-up roll 1 , and the strip steel 8 is rolled by the upper work roll 6 and the lower work roll 2 .

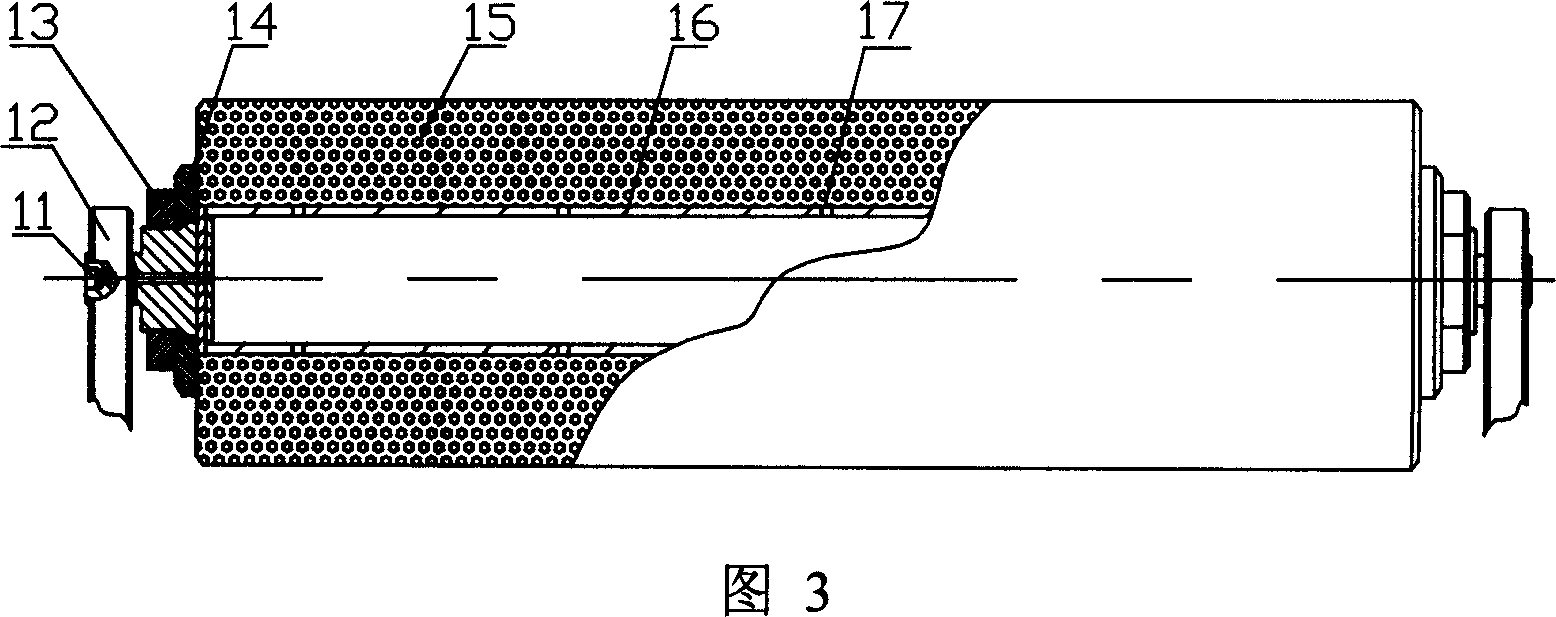

[0022] Referring to Fig. 3, the oiling roller 3 is composed of an oiling roller oil seepage layer 15 of the outer layer and an oiling roller shaft 16 of the inner layer, the oiling roller oil seepage layer 15 is made of an oil-permeable composite material, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com