Large-space hole-free rolling device and rolling method of bar production line

A production line and large spacing technology, applied in the field of metallurgy, can solve the problems of restricting the development of new technology and high technology of non-slotted rolling, the low output of bar production line, and the lack of market competitiveness of enterprises, so as to simplify the turning operation and storage The effect of reducing the amount and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

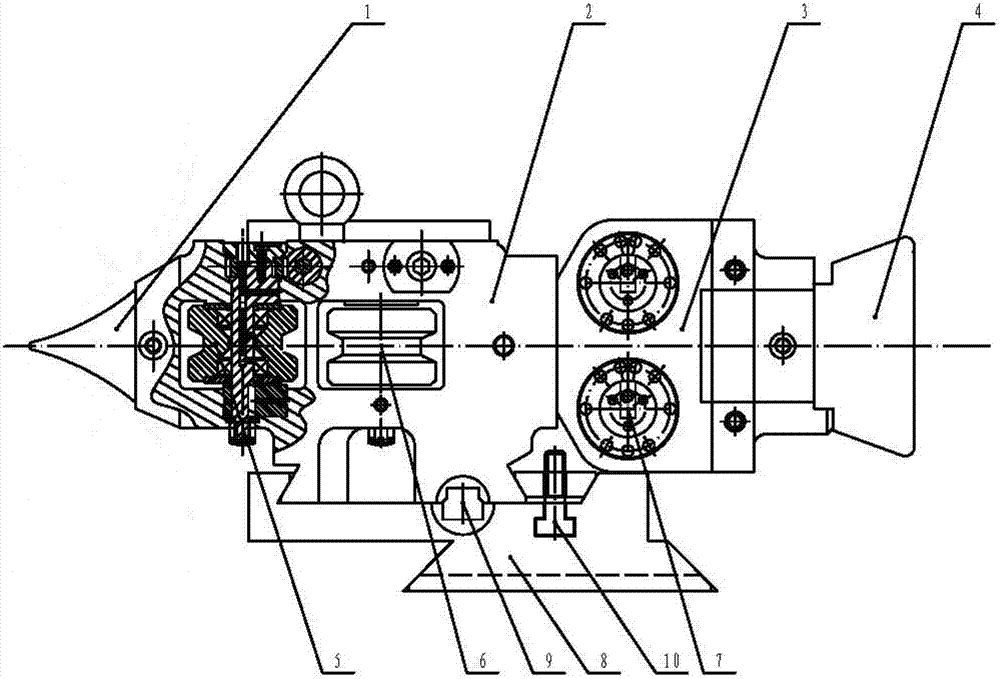

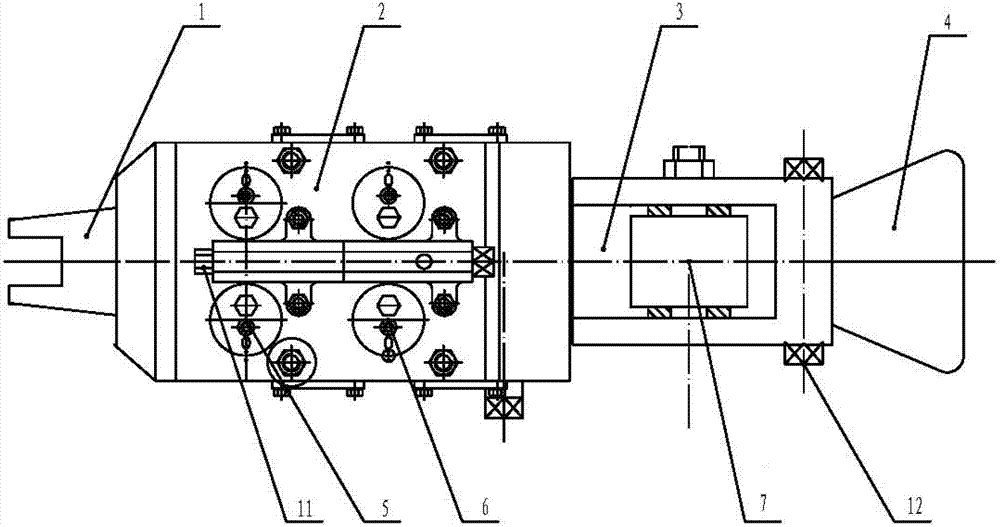

[0053] The device of this embodiment is as figure 1 As shown, a rolling device with large spacing and no holes for a bar production line includes a base 8 and a box body 2 installed on the base 8. The box body 2 is connected to the base 8 through an adjusting nut 9. The right end of the box body 2 A horizontal roller bracket 3 is provided, and the horizontal roller bracket 3 is connected to the base 8 through a T-shaped compression screw 10; There are two horizontal guide rollers 7, which are distributed parallelly up and down along the horizontal roller bracket 3, and the horizontal guide roller 7 is installed in the horizontal roller bracket 3, and the guide rollers can be adjusted flexibly; and, the horizontal roller bracket 7 is connected with bell mouth 4.

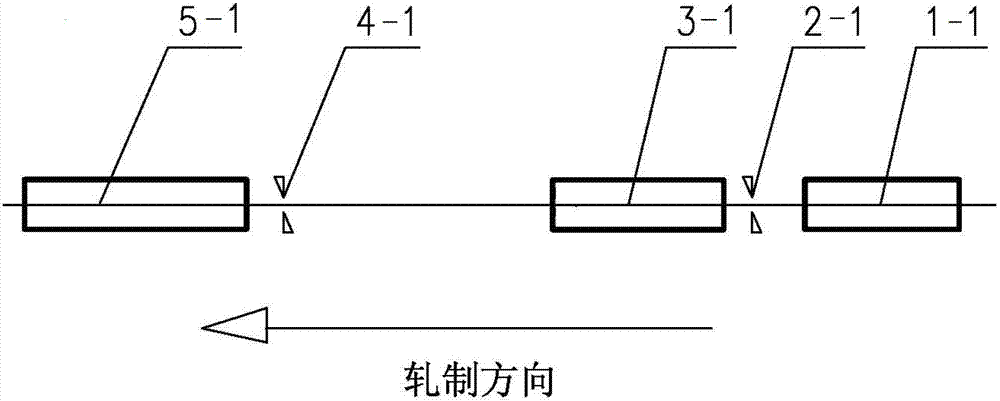

[0054] see figure 2 and combine figure 1 As shown, there are four v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com