Prediction method for flaw length of Cu-Al sandwich rolling-bonded band head

A technology of rolling compounding and prediction method, which is applied in the direction of metal rolling, metal rolling, length measuring device, etc., can solve the problems of cutting loss and reduction of output of compound strip head, and achieve the effect of increasing production and reducing cutting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

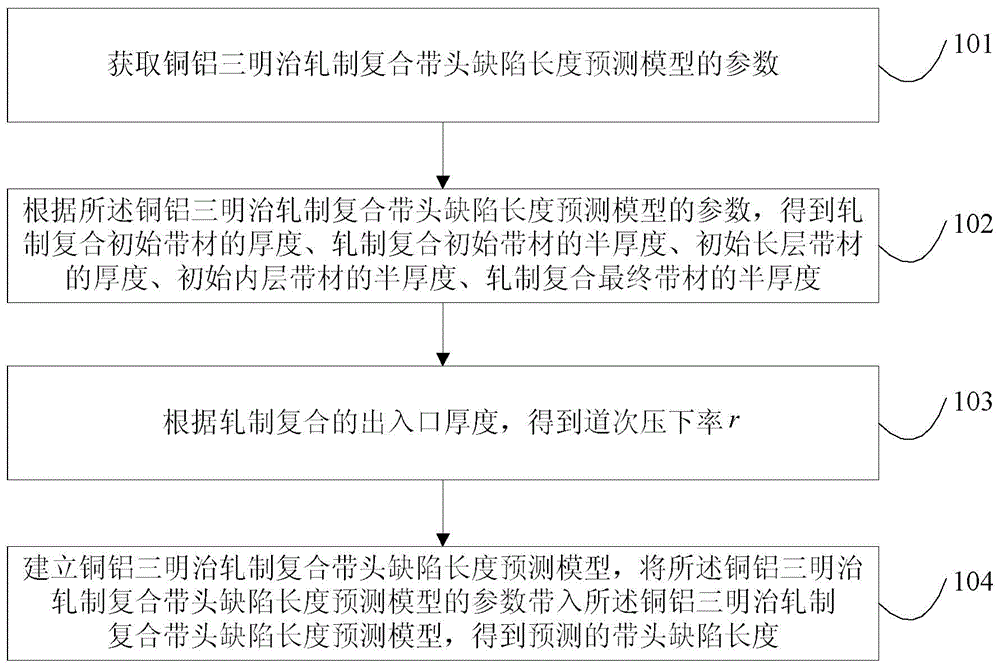

[0044] figure 1 It shows a schematic flow chart of the method for predicting the defect length of the copper-aluminum sandwich rolling composite strip head provided by an embodiment of the present invention, as shown in figure 1 As shown, the method of this embodiment is as follows.

[0045] 101. Obtain the parameters of the prediction model for the defect length of the copper-aluminum sandwich rolling compound strip head.

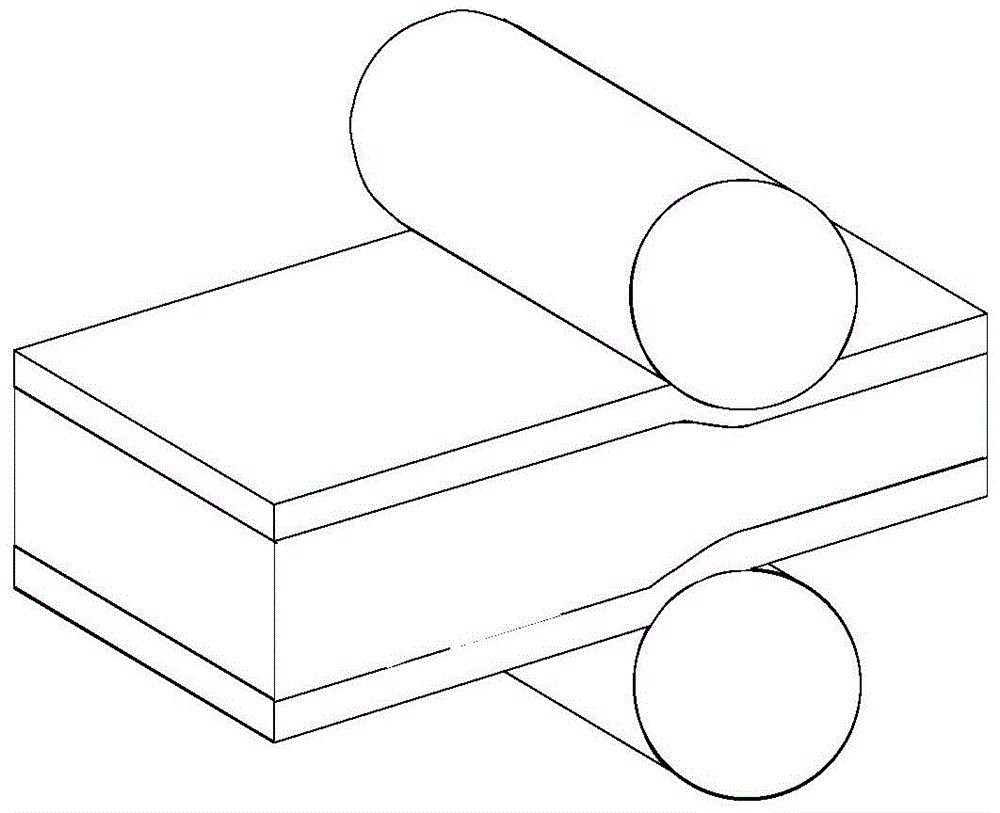

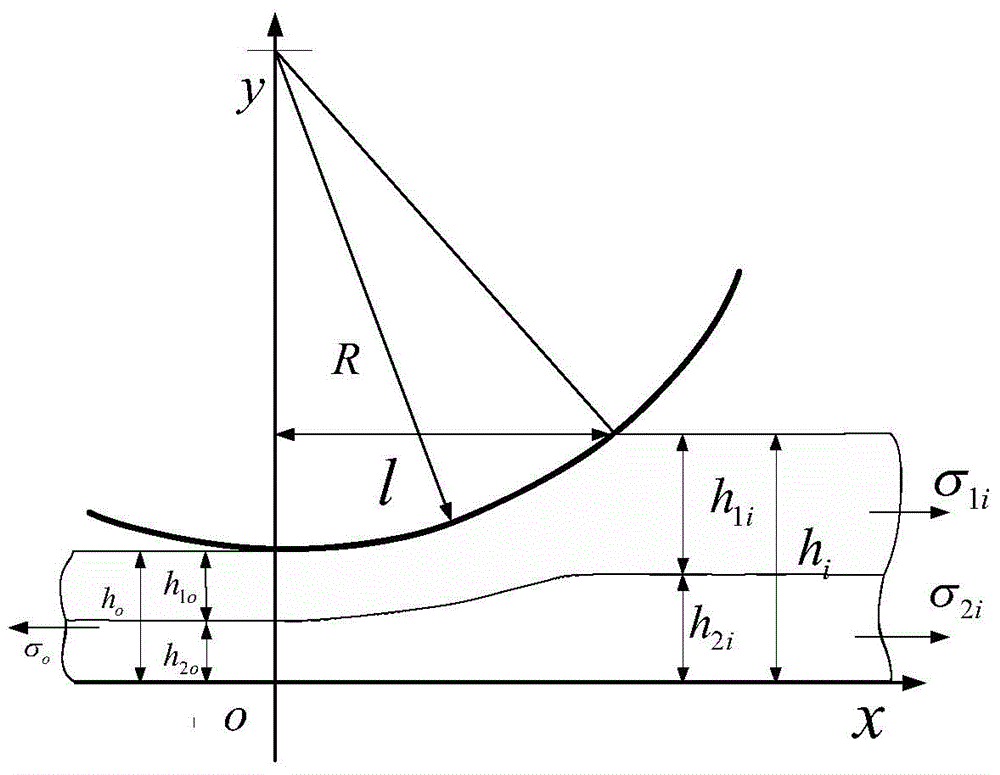

[0046] In this step, figure 2 A schematic diagram of a copper-aluminum composite provided by an embodiment of the present invention is shown, as figure 2 As shown, the upper and lower rolls are two rolls, and the middle is aluminum-copper-aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com