Steel-coil-sampling fixing device

A technology of fixing device and steel coil, applied in the direction of sampling device, etc., can solve the problems of operator injury, rewinding, cutting damage, etc., and achieve the effect of improving job safety factor, reducing cutting damage, and reducing the cost per ton of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

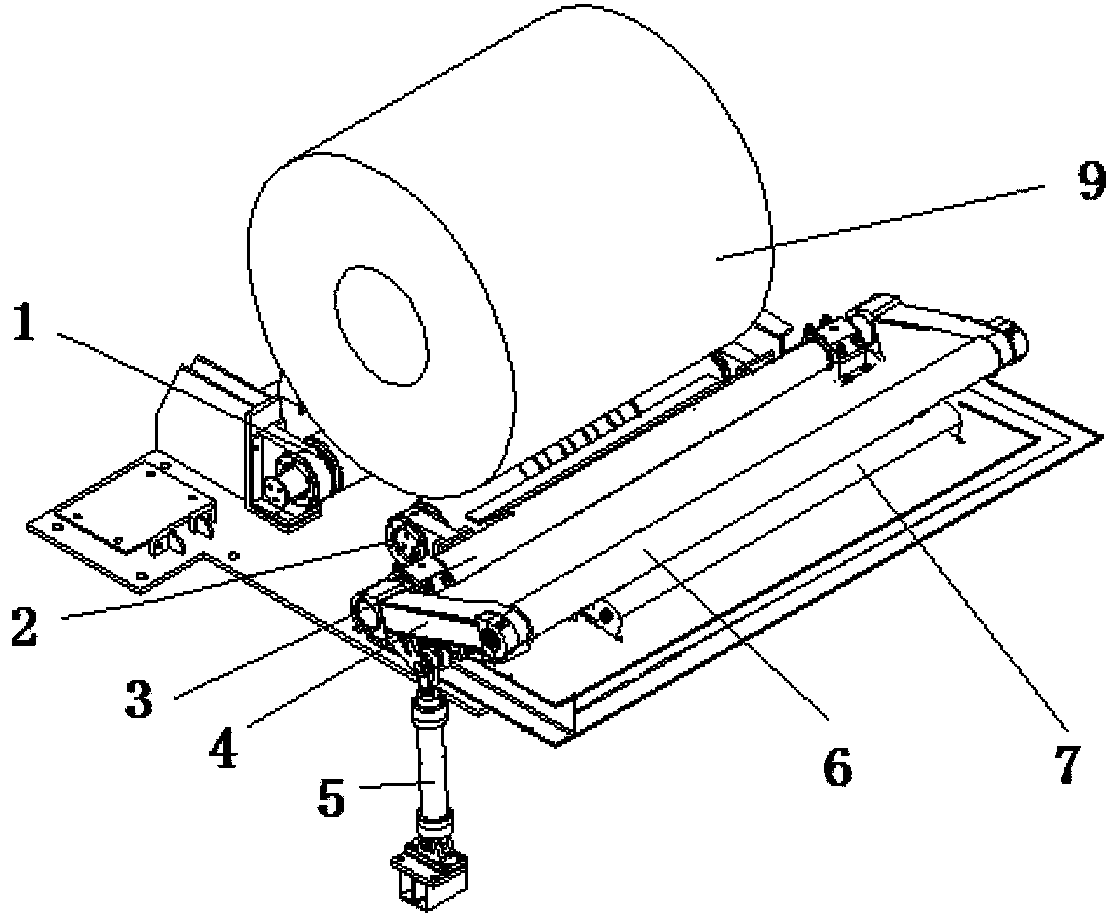

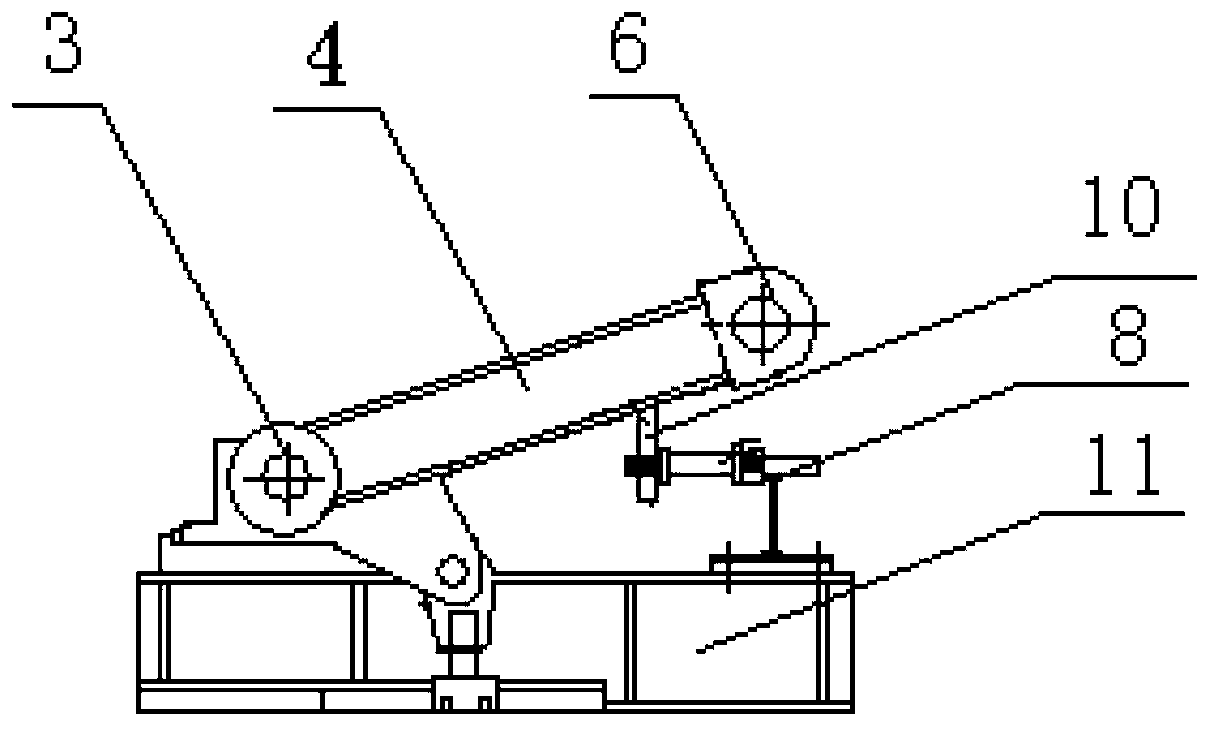

[0016] See figure 1 with figure 2 , The embodiment of the present invention provides a steel coil sampling and fixing device, which includes a ground roller active roller 1, a ground roller passive roller 2, a linkage shaft 3 arranged outside the ground roller passive roller 2, and swing arms connected to both ends of the linkage shaft 3. 4. The upper pinch roller 6 connected between the ends of the two swing arms 4, the lower pinch roller 7 located below the upper pinch roller 6, is connected to the swing arm 4, and the upper pinch roller can be controlled by driving the swing arm 4 6 The lifting swing hydraulic cylinder 5, and the locking device arranged at the lower part of the swing arm 4.

[0017] The locking device includes a metal plate 10 with a locking pin hole vertically arranged at the lower part of the end of the swing arm 4 close to the upper pinch roller 6, and a locking hydraulic cylinder 8 arranged horizontally at a position corresponding to the metal plate 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com