Control method of stretch-reducing mill steel tube thickening terminal

A control method and technology for steel pipes, which are applied in the direction of rolling mill control device, material size control, non-electric variable control, etc., can solve the problems of shortening the thickened end and not reaching the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

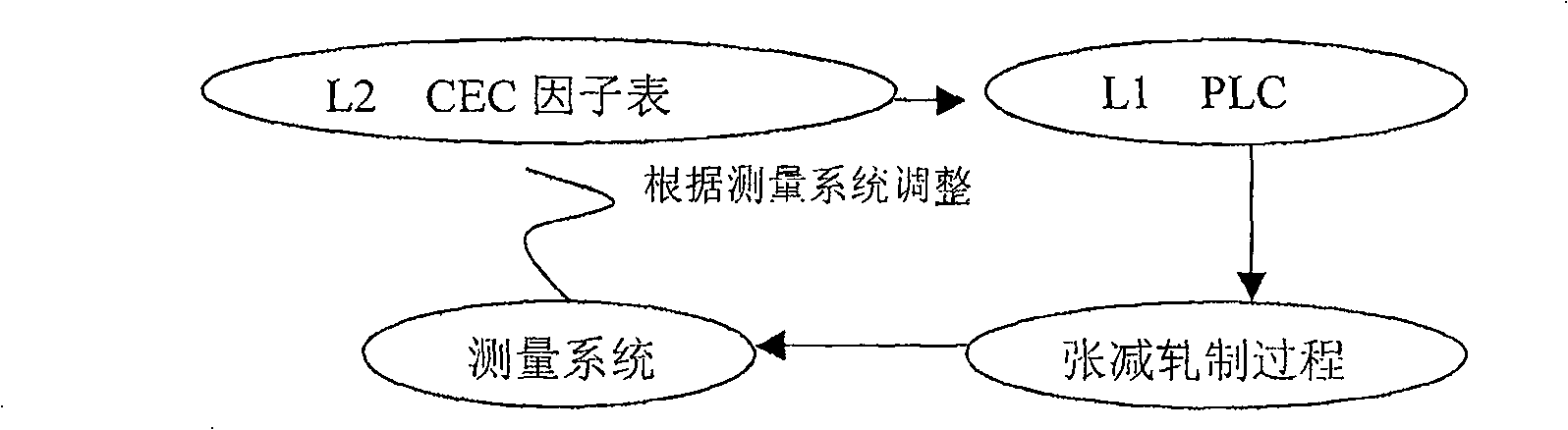

[0155] According to the rules described in the content of the invention, combined with different steel pipe specifications in the product outline, a new CEC factor table for all rolling specifications is calculated using a self-developed program. The new CEC factor table is stored in the database. The operator before rolling calls the CEC factor table at the same time when calling the rolling table, and enters the parameters of the CEC effect of the head and tail sections (head A factor and tail A factor) in the operation interface. factor).

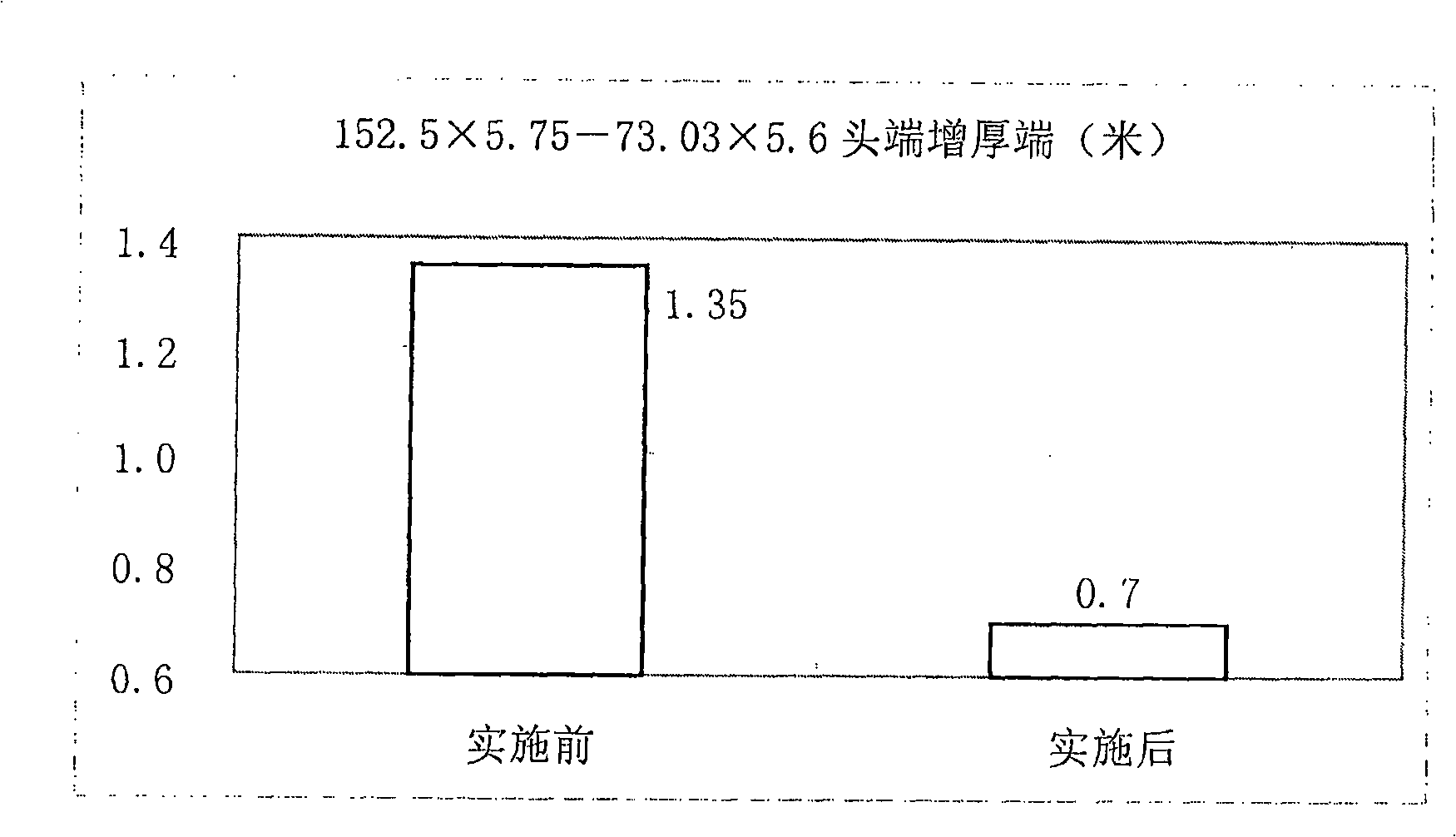

[0156] (1) Typical specifications of test steel pipes

[0157] The tension and reduction process of steel pipes with typical specifications of 152.5×5.75→73.03×5.6 was selected for the new CEC controlled production test. The specifications and parameters are shown in Table 4.

[0158] Table 4 Specification parameters of typical specification steel pipe φ73.03×5.6

[0159]

Hole type code

Outer diameter of waste pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com