Preparation equipment and method for prefabricated body with bent section

A preform and cross-section technology, applied in the field of resin matrix composite material molding, can solve the problems of deviation of performance value from expected design value, uncontrollable fiber deformation, uncontrollable external force, etc., to improve reliability and stability, reliability and repeatability. Good performance and the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

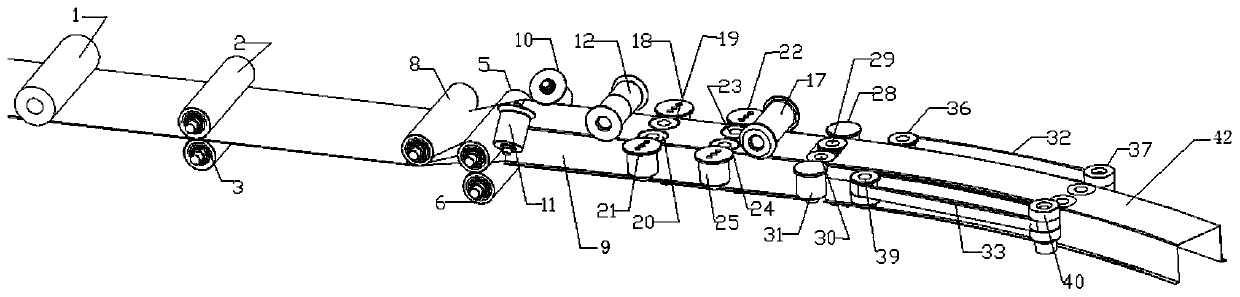

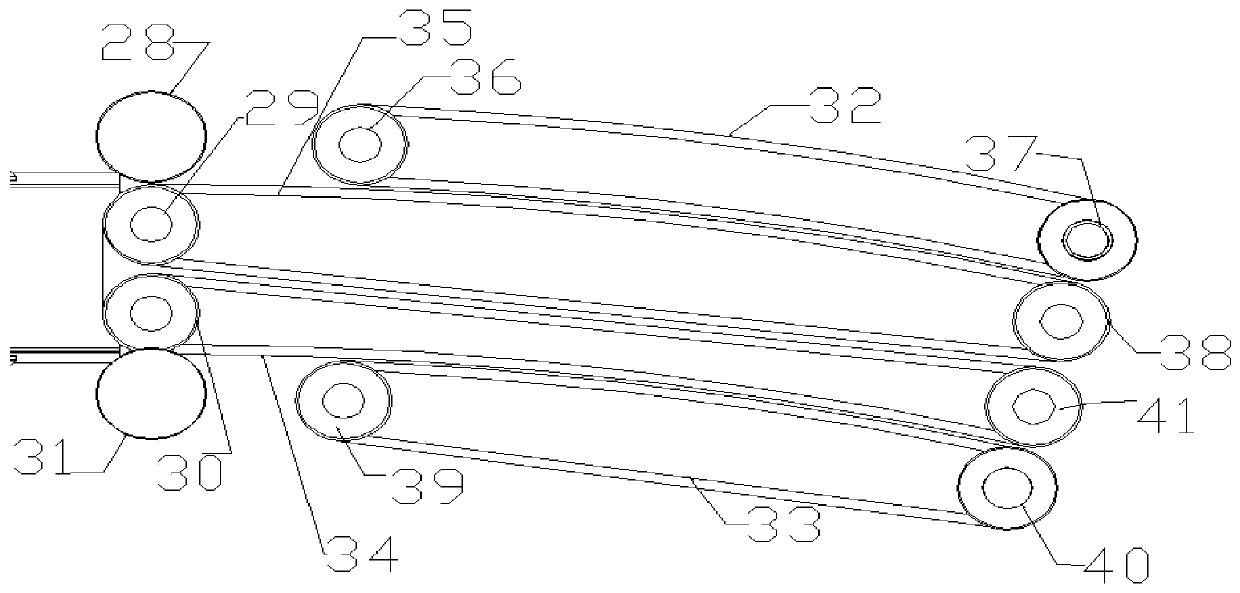

[0029] The preparation equipment with bent cross-section prefabricated body, the structure of the formed axially curved П-shaped composite material blank is: its cross-sectional shape is П-shaped, and the П-shaped composite material blank is composed of a web and edge strips on both sides Composition, the thickness is δ, the width of the web is b, the width of the outer edge strip is L1, the width of the inner edge strip is L2, and the edge strips on both sides are part of the concentric ring, and the circle of the ring where the inner edge strip is located The arc radius is R, the arc radius of the ring where the outer edge is located is R+b, the R angle between the inner edge and the web is R1, and the R angle between the outer edge and the web is R2.

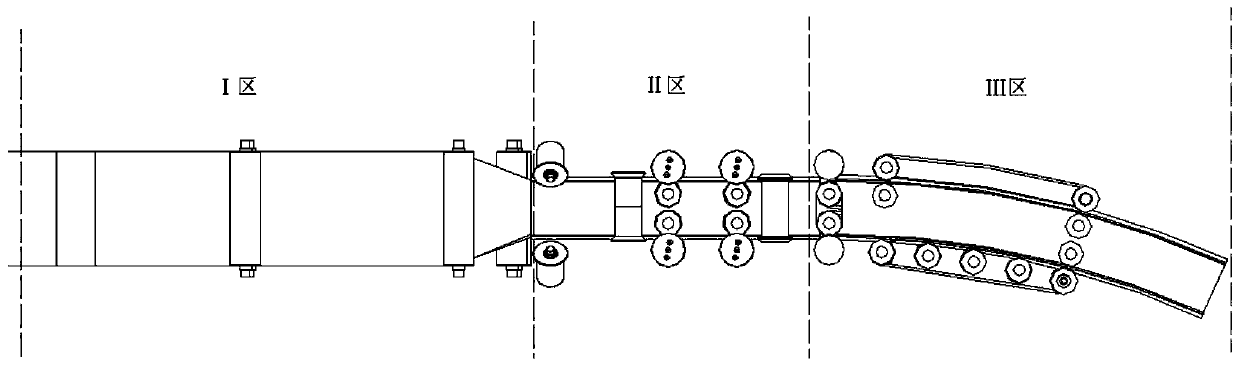

[0030] The preparation equipment for preforms with bent sections is divided into three areas: area I for feeding and guiding flat belts to rollers, area II for geometric section roll forming, and area III for bending roll form...

Embodiment 1

[0042] Example 1: Preparation of П-shaped beam prefabricated body with CF3031 / EP sizing agent

[0043]In this embodiment, the diameters of the inner and outer edge strips of the П-shaped beam are 2300mm and 2500mm respectively, and the thickness is 3mm. The strip material used is CF3031 fabric laminate, and the sizing agent is EP. Place the CF3031 / EP sizing fabric tape on the reel on the first template with a cross-section of П and extending along a straight line. According to the viscosity temperature test of the EP sizing agent resin, 70-90 ° C is selected as the molding temperature. Set the speed of each outer vertical roller in Zone II to 0.5m / min, set the speed of the vertical rollers outside the inner edge strip in Zone III to 0.54m / min, and set the speed of the vertical rollers outside the outer edge strip in Zone III to 0.5m / min. The speed of the rollers is set to 0.6m / min, and the gap between the vertical roller pairs is adjusted to 3mm. Press the cylinder, turn on t...

Embodiment 2

[0044] Example 2: Preparation of Z-beam prefabricated body with CFF3031 / EP sizing agent

[0045] The difference between this embodiment and Embodiment 1 is that the prefabricated body structure is changed from П-shaped to Z-shaped; The shape and surface are consistent, and other operations are the same as in Example 1, and the Z-shaped prefabricated body is obtained with good quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com