Aluminum alloy profile torque correction device

A technology of aluminum alloy profiles and torque, applied in the field of hard aluminum alloy profile torque correction equipment, to achieve strong adaptability, reduce cutting loss, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

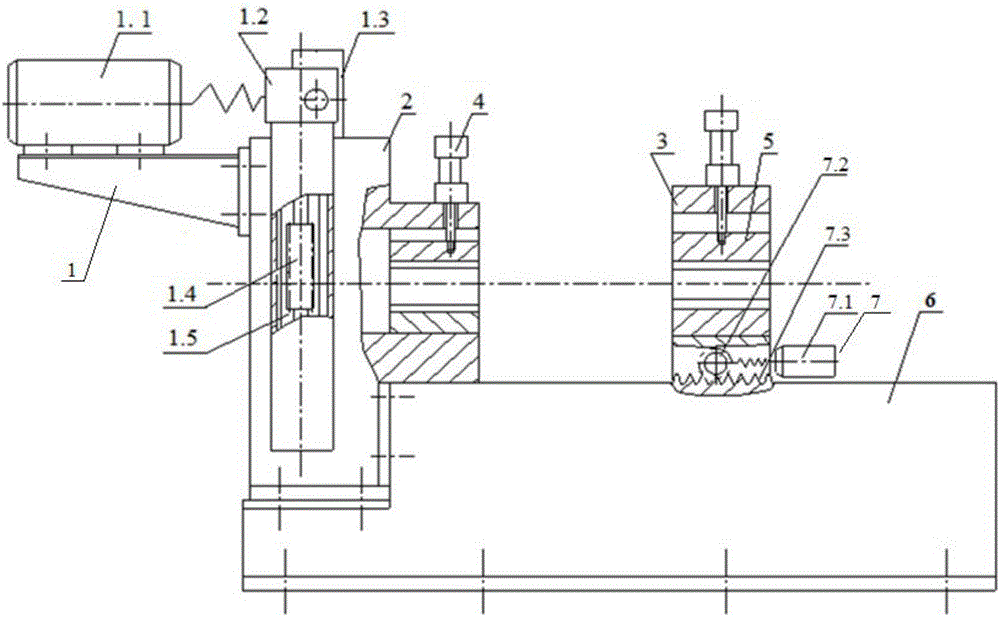

[0020] Such as figure 1 As shown, the present invention discloses an aluminum alloy profile torque correction equipment, including a torsion transmission mechanism 1, a fixed torsion base 2, a movable clamping base 3, a front end profile clamping device 4, a rear end profile clamping device 5, The bed 6 and the driving device 7, the side of the torsion transmission mechanism 1 is connected with the front-end profile clamping device 4, the base of the torsion transmission mechanism 1 is connected with the fixed torsion base 2 by bolts, and the fixed torsion base 2 is connected by bolts Connected with the bed 6, the bed 6 is provided with a mobile clamping base 3 that can slide along the track on the bed 6, the bottom of the mobile clamping base 3 is connected with a driving device 7, and the mobile clamping machine The upper side of the seat 3 is connected with a rear-end profile clamping device 5, and the center lines of the front-end profile clamping device 4 and the rear-end...

Embodiment 2

[0023] On the basis of Embodiment 1, the fixed twist base 2 is connected to the end of the bed 6 by bolts, and the twist transmission mechanism 1 is installed on the base of the fixed twist base 2, and the twist transmission mechanism 1 is driven by a motor 1.1 , steering box 1.3, worm gear box 1.2, long worm 1.4 and large worm gear 1.5, the input shaft of the steering box 1.3 is connected with the output shaft of the motor 1.1, the output shaft of the steering box 1.3 is connected with the worm shaft of the worm gear box 1.2 , the worm gear of worm gear box 1.2 is connected with long worm screw 1.4, and long worm gear 1.4 meshes with big worm gear 1.5; Described worm gear and worm gear box 1.2, steering box 1.3, long worm screw 1.4 are respectively connected with fixed torsion base 2 by bolts, and big worm gear 1.5 is connected to the fixed torsion machine base 2 through the rotating shaft; the side of the large worm wheel 1.5 is connected with the front-end profile clamping d...

Embodiment 3

[0026] On the basis of Embodiment 1, the mobile clamping base 3 slides along the track on the bed 6 under the drive of the driving device 7, and the distance between the mobile clamping base 3 and the fixed twisting base 2 can be adjusted by moving the clamping The driving adjustment of the frame driving device 7 can realize the torsion correction needs of profiles with different lengths. The drive device 7 is composed of a reduction motor 7.1, a gear 7.2 and a rack 7.3, the motor shaft of the reduction motor 7.1 is sleeved on the gear shaft of the gear 7.2, and the gear 7.2 and the rack 7.3 are meshed and connected; The bar 7.3 is installed on the bed 6, the gear 7.2 is installed on the mobile clamping base 3, and the mobile clamping base 3 slides along the track on the bed 6 under the engagement of the gear 7.2 and the rack 7.3. When the mobile clamping base 3 moves, the reduction motor 7.1 of the driving device 7 drives the gear 7.2 to move, and the gear 7.2 realizes the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com