Drawing and rolling combined type multi-plate continuous forming method for variable-section plate springs

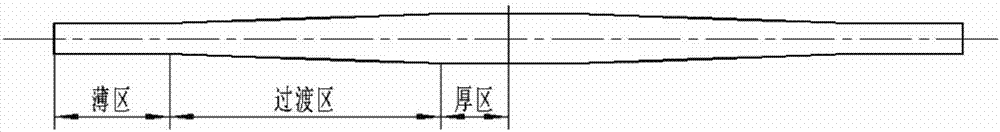

A variable-section, leaf spring technology, applied in the field of metal processing, can solve the problems of large end cutting loss and low production efficiency, and achieve the effects of improving production efficiency, reducing end cutting loss and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings. The steps of the present invention are as follows:

[0016] Blanking: Multi-piece combined cutting method is adopted, the length of sheet 1 is n times the length of single sheet, and the specific size is calculated according to the principle of constant volume;

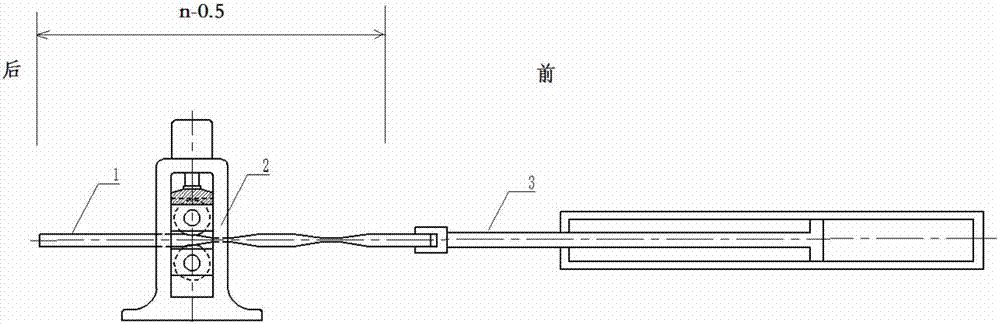

[0017] Heating of n-0.5 pieces at the rear end: heating one end of the plate, the heating length is n-0.5 plate spring plate length, and the heating temperature is 800-950°C;

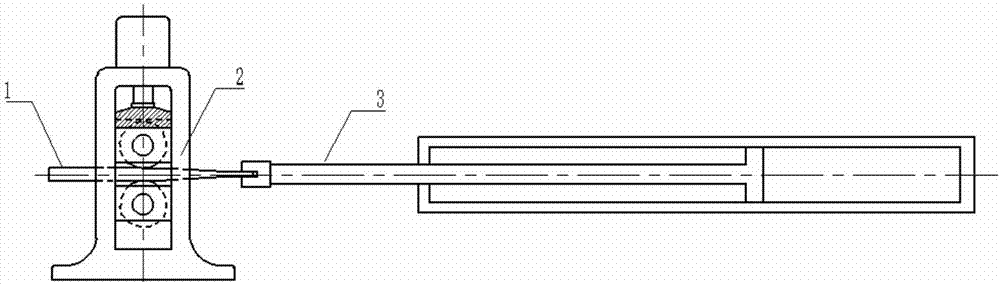

[0018] Rolling of n-0.5 sheets at the rear end: place the unheated section of the sheet material 1 at the front, send it into the variable-section rolling mill 2, and reach the drawing machine 3. The drawing machine 3 clamps the sheet and starts to move forward. At the same time, the variable-section rolling mill 2 Adjust the roll gap in real time according to the set curve, the rolling process is as follows figure 2 shown;

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com