Method for reducing cutting thickness of solar polycrystalline silicon chip

A polysilicon wafer, cutting thickness technology, applied in the direction of fine working equipment, stone processing equipment, manufacturing tools, etc., can solve the problems of insufficient tensile strength of cutting steel wire, lower silicon wafer pass rate, large steel wire cutting, etc., to achieve Good for cutting efficiency, high cutting efficiency and small cutting gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

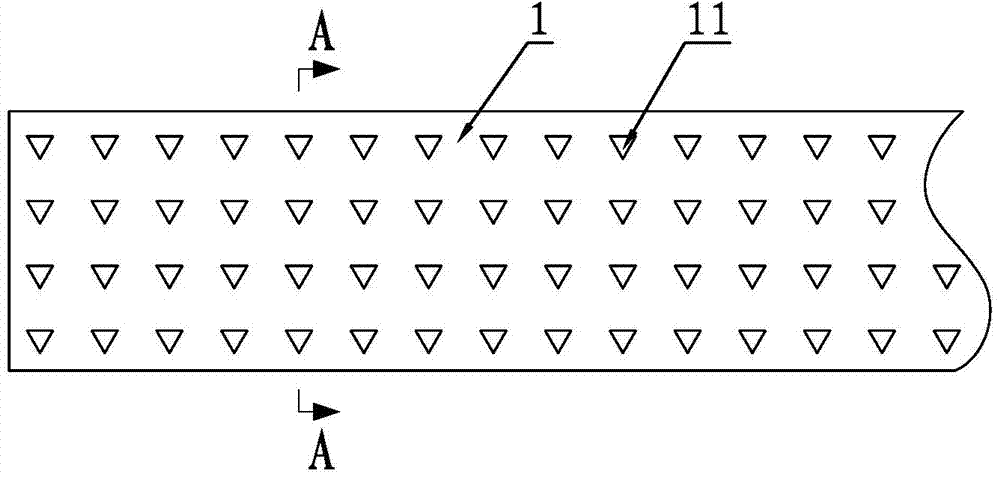

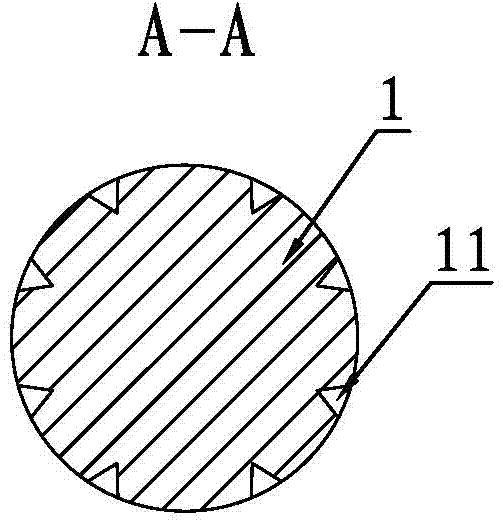

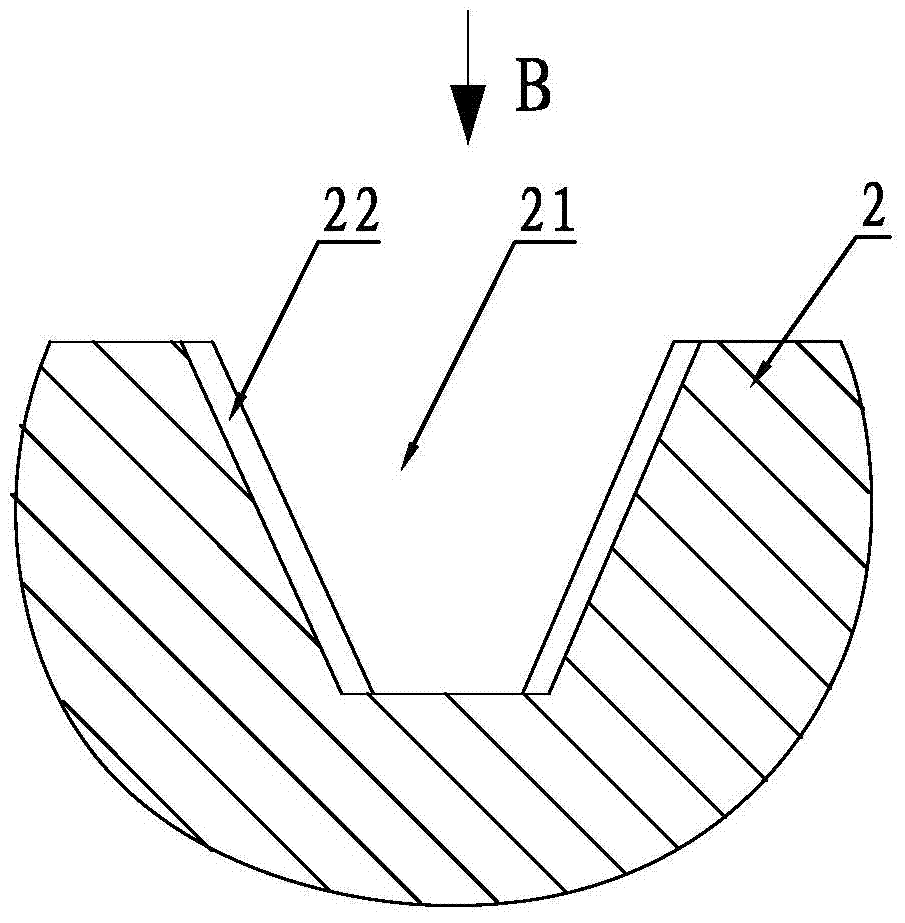

[0022] A method for reducing the cutting thickness of solar polysilicon wafers, such as Figure 1 to Figure 5 As shown, the cutting steel wire adopts a special-shaped cutting steel wire 1 with a diameter of 110-115 microns, the groove spacing of the guide wheel groove 21 on the guide wheel 2 is 320-330 microns, and the silicon carbide particles in the mortar have a particle size of 8.2-8.6 microns. The polygonal body, on the outer surface of the special-shaped cutting steel wire 1 is provided with a non-circular groove 11, the cross-sectional shape of the guide wheel groove 21 is isosceles trapezoidal, along the two sides of the guide wheel groove 21 The overflow grooves 22 are equidistantly arranged in the circumferential direction, the cross-sectional shape of the overflow grooves 22 is an isosceles trapezoid, the cross-sectional shape of the non-circular grooves 11 is triangular, and the non-circular grooves 11 are equidistantly arranged on the steel plate. On the outer sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com