Accurate distribution method for slab resources of iron and steel enterprise

A distribution method and slab technology, applied in the information field, can solve the problems of reducing non-commissioned inventory, no consideration, etc., and achieve the effects of reducing slab cutting loss and inventory, reducing energy waste, and precise allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

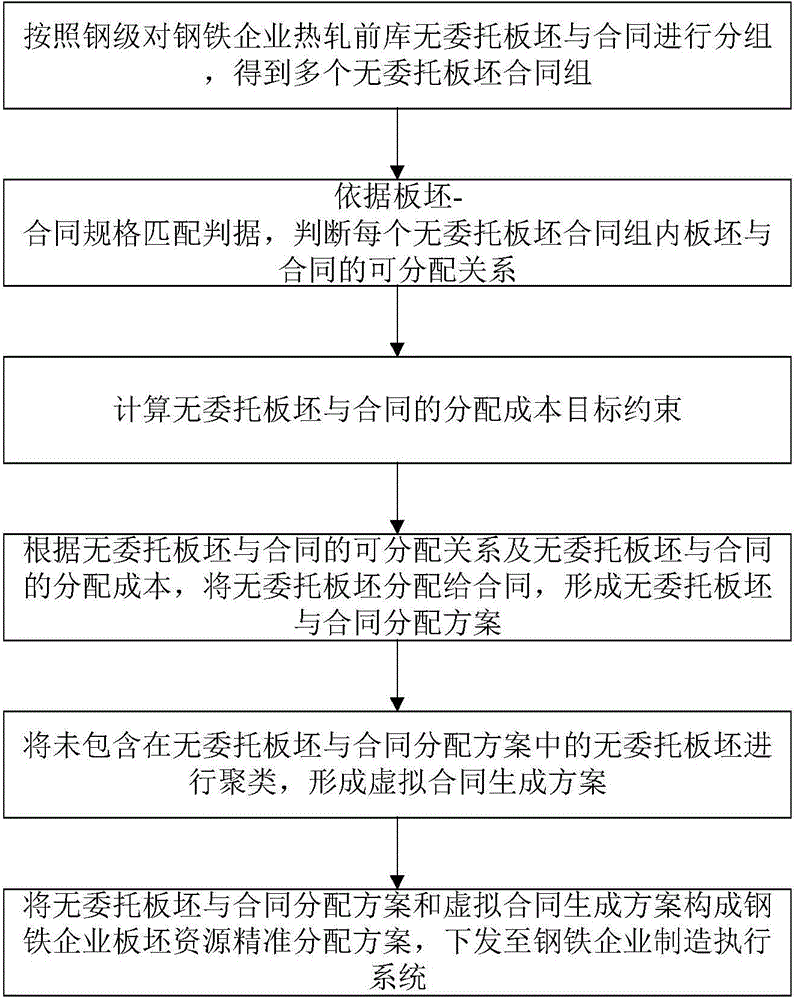

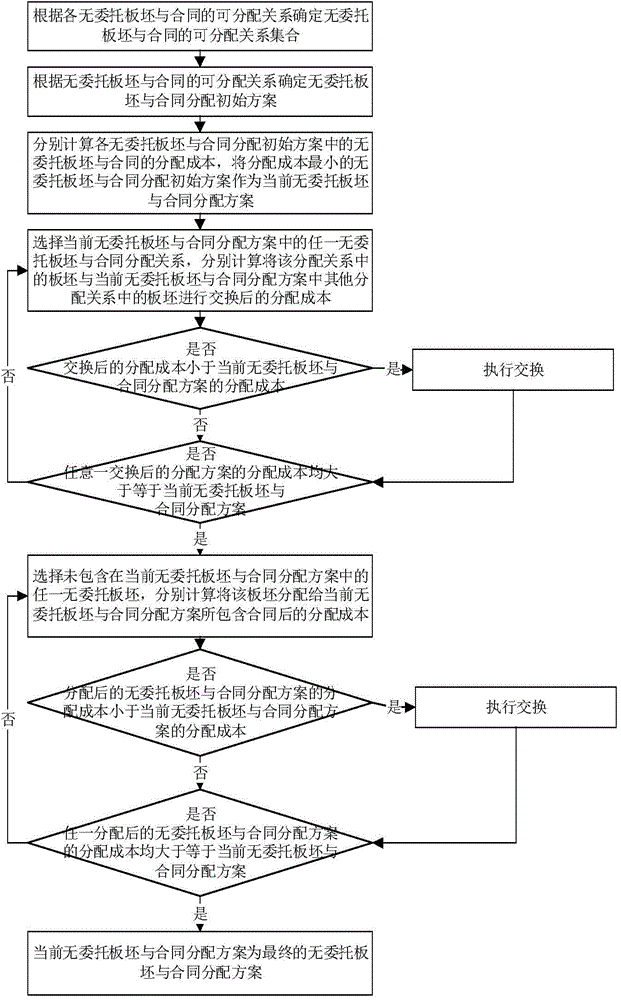

[0064] A method for precise allocation of slab resources in iron and steel enterprises, such as figure 1 shown, including the following steps:

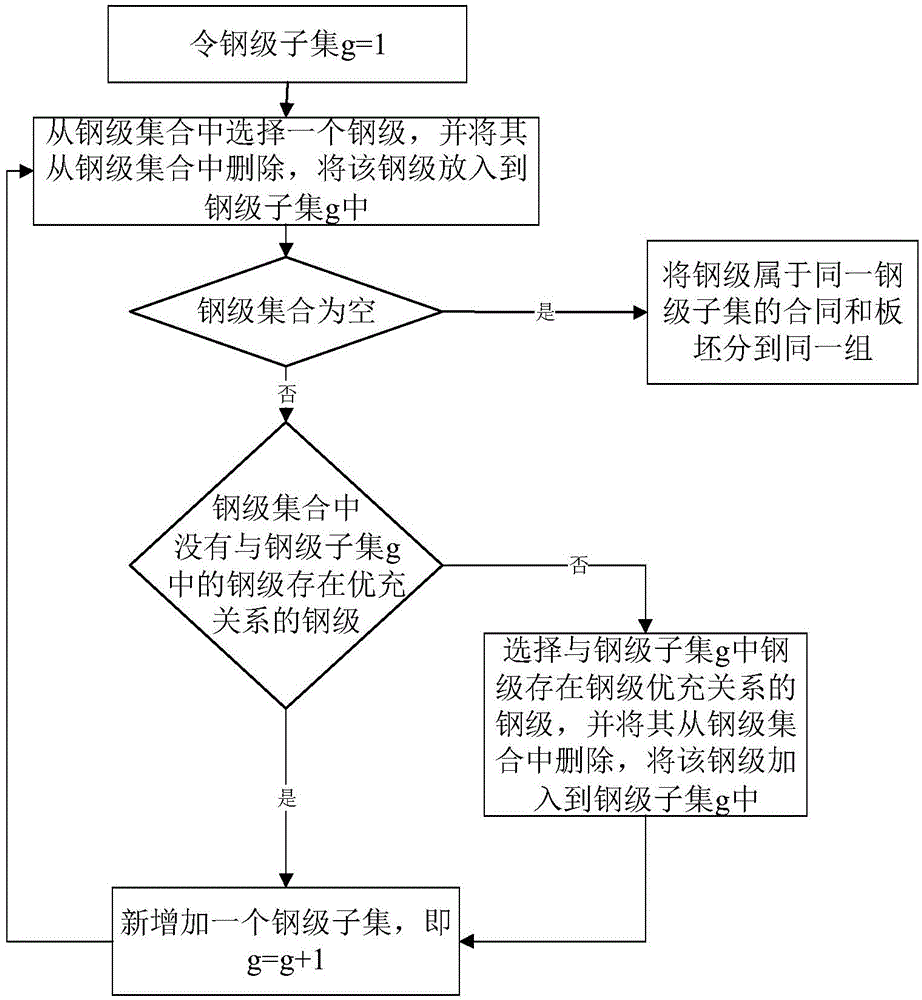

[0065] Step 1: Group the non-entrusted slabs and contracts in the hot rolling front warehouse of iron and steel enterprises according to the steel grade, and obtain multiple non-entrusted slab contract groups. The specific steps are as follows figure 2 shown;

[0066] Step 1.1: Make the steel grade subset g=1, select a steel grade from the steel grade set, and delete it from the steel grade set, put the steel grade into the steel grade subset g, if the steel grade set If it is empty, go to step 1.4, otherwise go to step 1.2;

[0067] Step 1.2: From the steel grade set, select the steel grade that has a steel grade superiority relationship with the steel grade in the steel grade subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com