Imbricated assembly and manufacturing method thereof

A technology of components and solar cells, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc. Problems such as the long transmission distance of the flow sub-grid can reduce the longitudinal long-distance transmission loss of the current, increase the efficiency of the shingled module, and reduce the cutting loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084]Referring now to the drawings, specific embodiments of the invention are described in detail. It will be described herein only, according to the preferred embodiments of the present invention, and those skilled in the art can achieve other means of the present invention in the light embodiments, the otherwise, which can also fall into the scope of the invention.

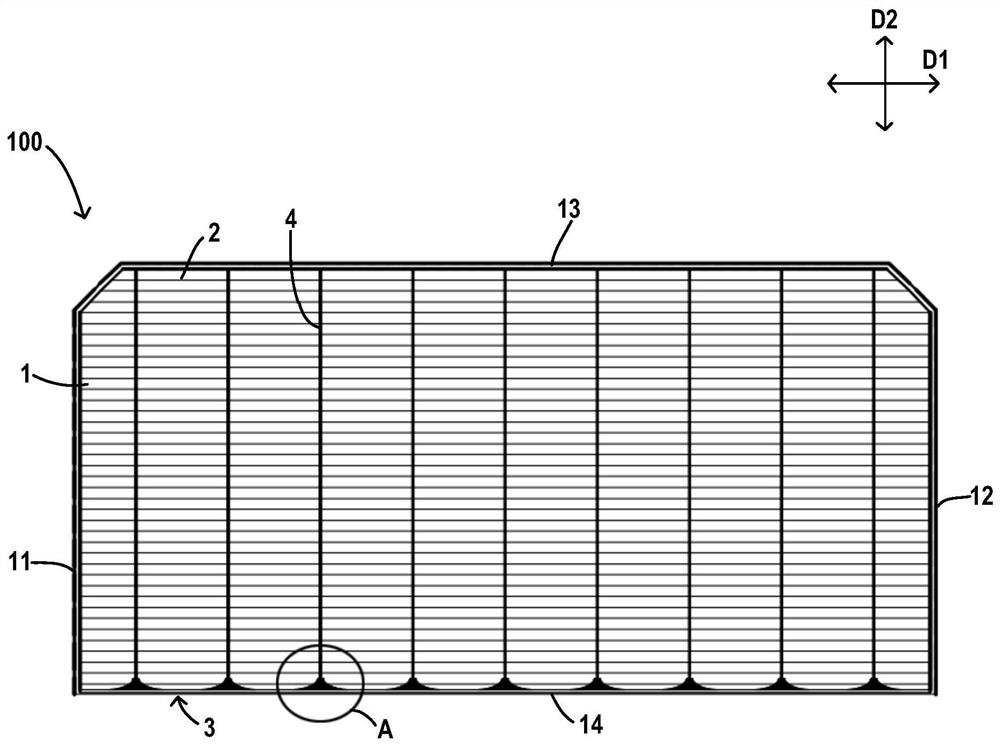

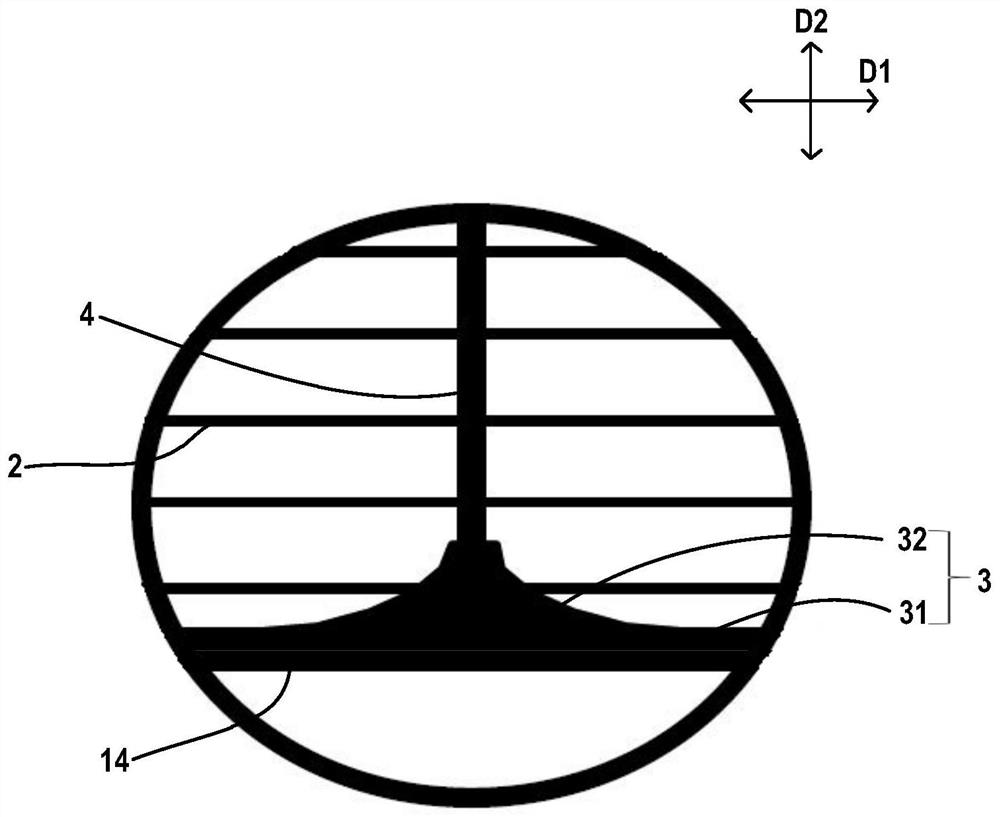

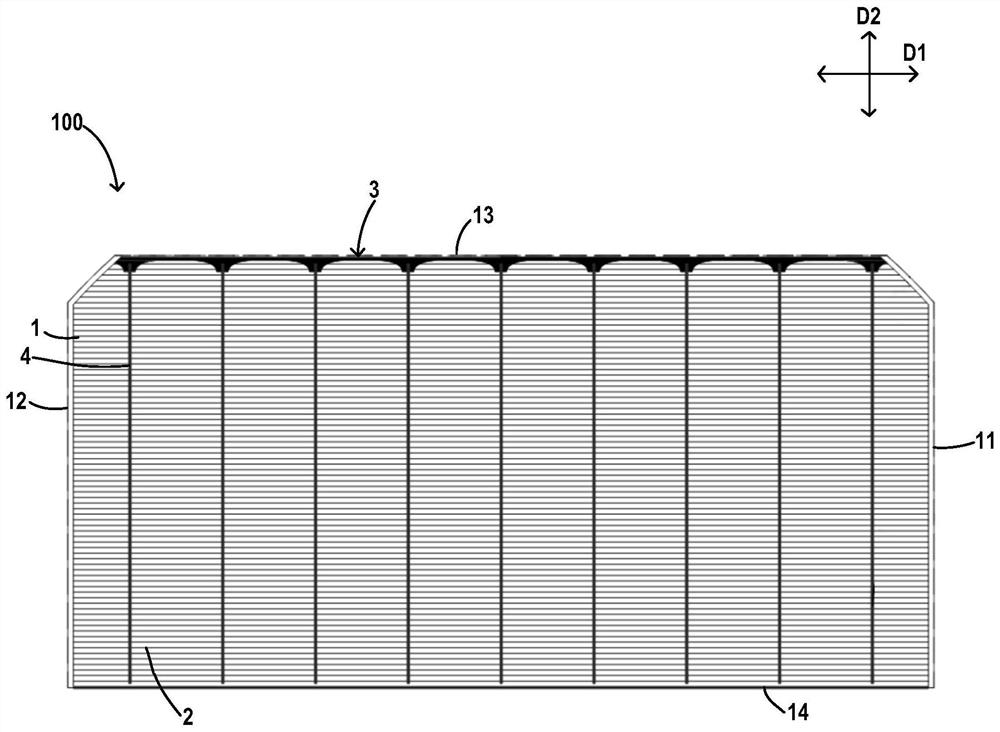

[0085]The present invention provides a superimposed tile assembly and a method of manufacturing the same.Figure 1 - Figure 6 Some preferred embodiments of the superimpillar assembly provided by the present invention are shown. First, it is to be noted that the first direction and the second direction mentioned herein are two directions that are substantially perpendicular to each other, and the plane defined in the first direction and the second direction is parallel to the top surface of the solar cell sheet, the bottom surface. In the first direction, the second direction is shown by D1 and D2, respectively.

[0086]Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com