Cutting method for reducing cutting loss of LED chip

A technology of LED chip and cutting method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of large loss of light-emitting area of the chip, increase of contact area between the back of the blade and the surface of the chip, and cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

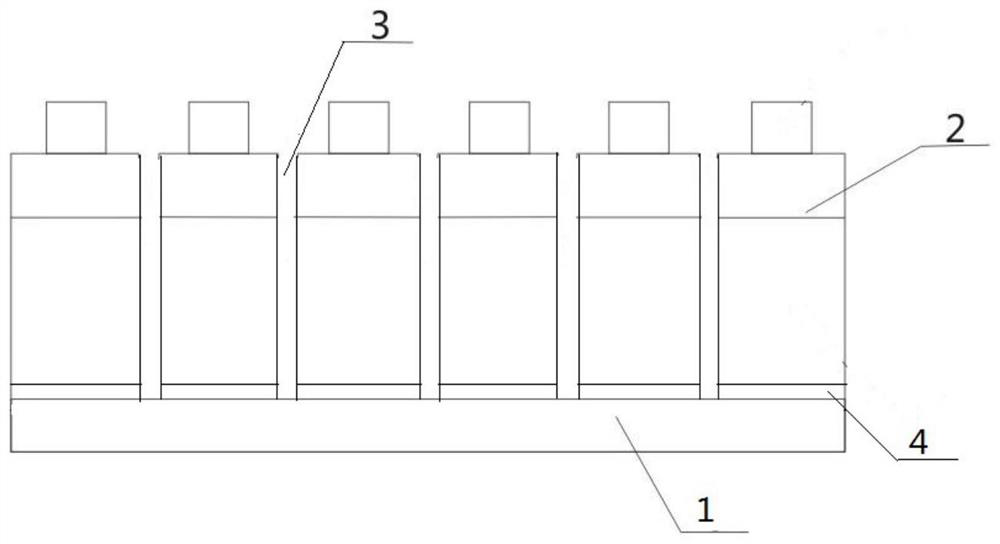

Image

Examples

Embodiment 1

[0064] Step 1: Prepare the LED chip;

[0065] Step 2: Take the prepared LED chip, and cut the P side of the LED chip into half at intervals according to the period set by the process; the cutting depth is 5% of the thickness of the LED chip;

[0066] Step 3: Take the half-cut LED chip and test it with a testing machine. The test current is 20mA, the test time is 5ms, and the corresponding brightness, voltage and wavelength of the LED chip are tested;

[0067] Step 4: Adsorb the tested LED chip on the suction cup of the glue homogenizer, use the glue homogenizer to apply negative glue on the P surface, and form a protective film on the P surface after coating; the speed of the glue homogenizer suction cup is first 2500r / 3000r / min after min, the glue thickness is

[0068] Step 5: Place the glue-coated LED chip on the platform of the photolithography machine for light exposure, and expose the cutting line on the protective film; the light intensity during exposure is 6 μW / cm ...

Embodiment 2

[0079] Step 1: Prepare the LED chip;

[0080] Step 2: Take the prepared LED chip, and cut the P side of the LED chip into half at intervals according to the period set by the process; the cutting depth is 8% of the thickness of the LED chip;

[0081] Step 3: Take the half-cut LED chip and test it with a testing machine. The test current is 20mA, the test time is 5ms, and the corresponding brightness, voltage and wavelength of the LED chip are tested;

[0082]Step 4: Adsorb the tested LED chip on the suction cup of the glue homogenizer, and use the glue homogenizer to apply negative glue on the P surface, and form a protective film on the P surface after the glue is applied; the speed of the glue homogenizer suction cup is first 3000r / 4000r / min after min, the glue thickness is

[0083] Step 5: Place the glue-coated LED chip on the platform of the photolithography machine for light exposure, and expose the cutting line on the protective film; the light intensity during expos...

Embodiment 3

[0094] Step 1: Prepare the LED chip;

[0095] Step 2: Take the prepared LED chip, and cut the P side of the LED chip into half at intervals according to the period set by the process; the cutting depth is 10% of the thickness of the LED chip;

[0096] Step 3: Take the half-cut LED chip and test it with a testing machine. The test current is 20mA, the test time is 5ms, and the corresponding brightness, voltage and wavelength of the LED chip are tested;

[0097] Step 4: Adsorb the tested LED chip on the suction cup of the glue homogenizer, use the glue homogenizer to apply negative glue on the P surface, and form a protective film on the P surface after coating; the speed of the glue homogenizer suction cup is first 4000r / 5000r / min after min, the glue thickness is

[0098] Step 5: Place the glue-coated LED chip on the platform of the photolithography machine for light exposure, and expose the cutting line on the protective film; the light intensity during exposure is 10μW / cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com