Multi-wire cutter special for sapphire

A multi-wire cutting machine and sapphire technology, which is applied to stone processing equipment, working accessories, fine working devices, etc., can solve the problems that the cutting quality cannot meet the application requirements, the thickness control of the cutting material is difficult to grasp, and the production cost is high. Achieve the effect of long trouble-free running time, fast net feeding speed and small cutting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

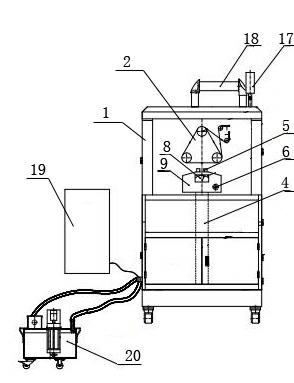

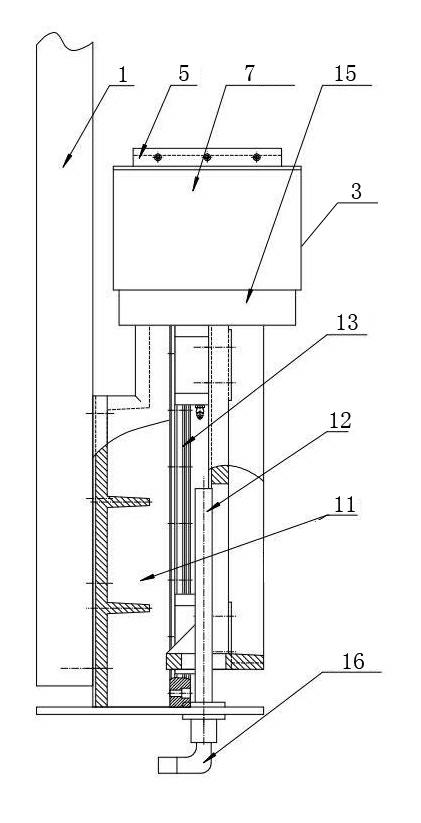

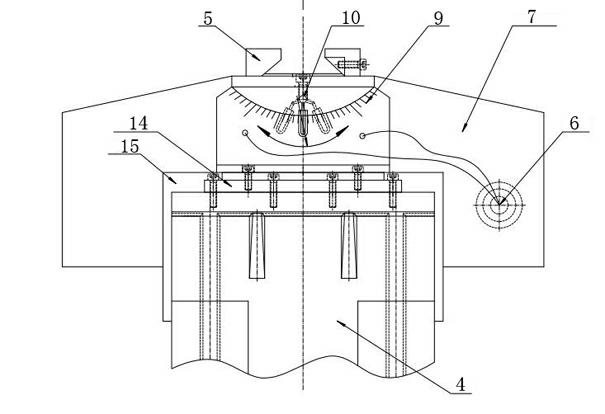

[0017] A special multi-wire cutting machine for sapphire, including a body 1, a cutting wire mechanism 2, a swing table 3, and a lifting body 4. The swing table, the lifting body drives the swing table to move up and down, and the swing table itself swings left and right, so that the workpiece on the swing table cooperates with the cutting wire mechanism to complete sapphire multi-line cutting. Said swing workbench comprises dovetail groove workbench 5 and the stepper motor 6 connected with it, and stepper motor drives dovetail groove workbench to swing left and right. The swing workbench is also provided with a workbench shield 7, an observation window 8, a dial 9, and a scale 10. An observation window is arranged on the workbench shield, and a matching dial and scale are arranged in the observation window. Said lifting body comprises body 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com