Weft selecting mechanism for big tows

A large tow and weft selection technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of limited weft selection, large running resistance, poor clamping effect of rapier chucks, etc., and achieve movement resistance Small, reduced friction fracture, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

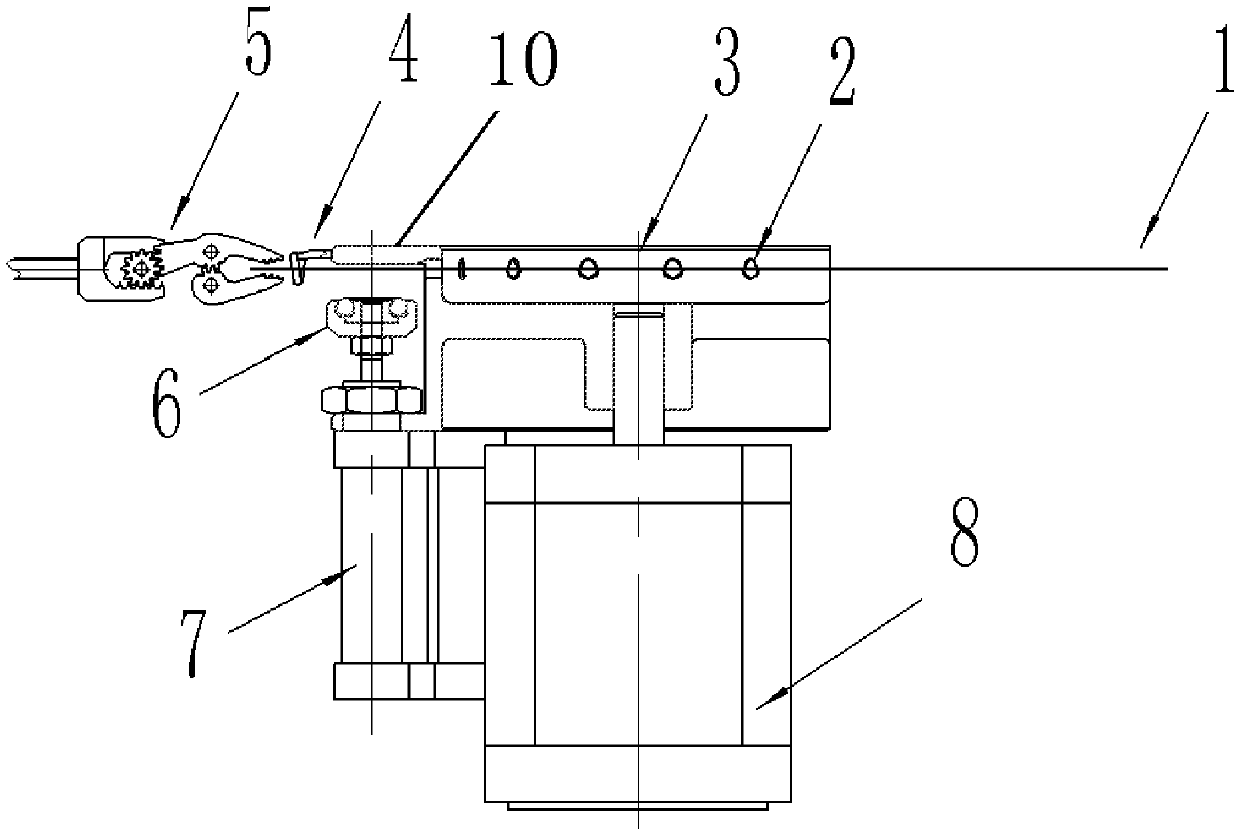

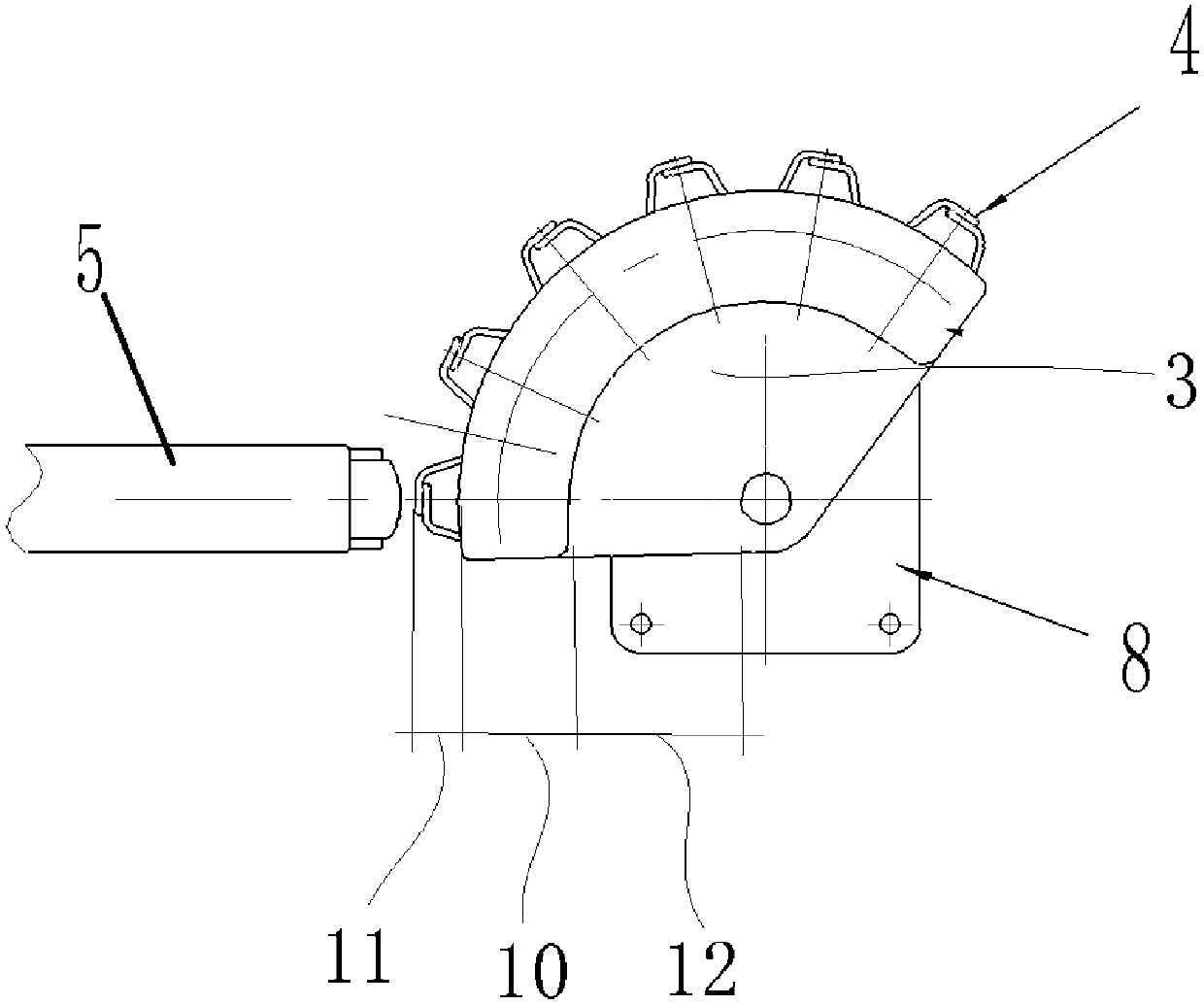

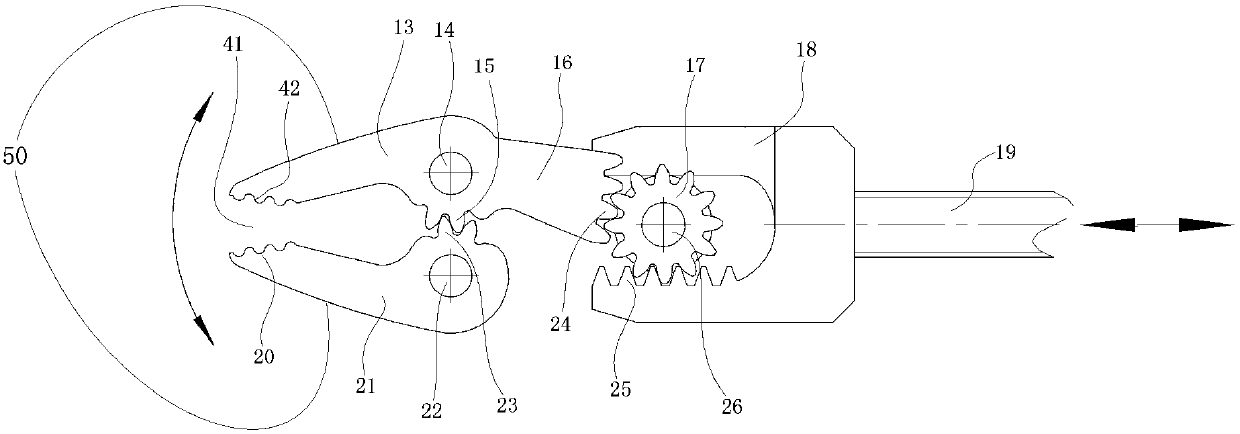

[0037] as attached figure 1 and 2 Shown, a kind of weft selection mechanism of large tow, rapier chuck 5 and multi-selection turntable 3; Described multi-selection turntable 3 is provided with several groups of guide channels, and in the present embodiment, guide channels can be one to Dozens of groups, the number of groups of yarn guide channels is selected according to production requirements, and the yarn guide channels can pass through large tow fibers 1, wherein the large tow fibers 1 include large tows including glass fibers, quartz fibers, carbon fibers, basalt fibers, Boron fiber, aramid fiber or silicon carbide fiber; rotating the multi-choice turntable 3 can make the yarn outlet end of each group of the yarn guide channels correspond to the clamping part 41 of the rapier chuck 5 in turn, and the rapier chuck 5 can clamp the large tow fiber 1 corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com