Control method of intelligent low-pressure drawer unit system

A drawer unit and low-voltage drawer technology, which is applied in the field of low-voltage switchgear, can solve problems such as labor-intensive work, damage to drawer units, and damage to plug-ins inside the drawer, and achieve the effects of saving labor costs, broad application prospects, and smooth linear motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

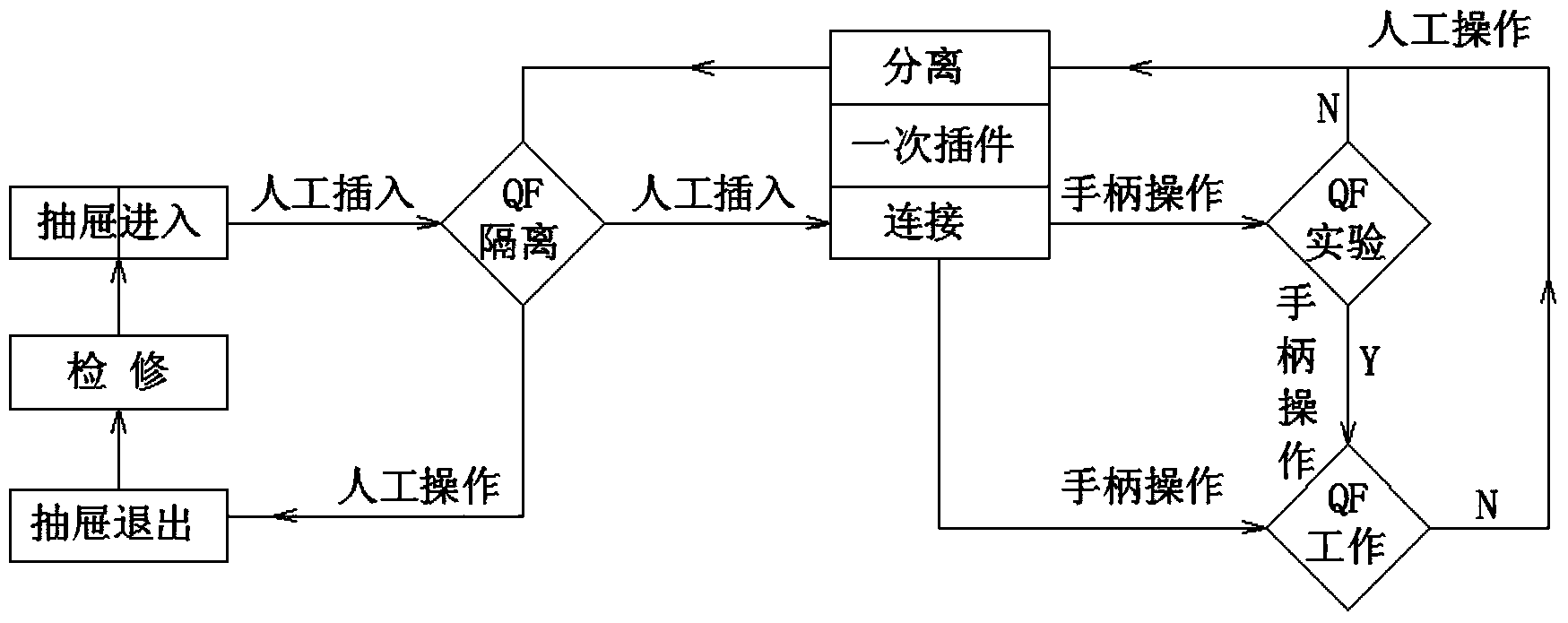

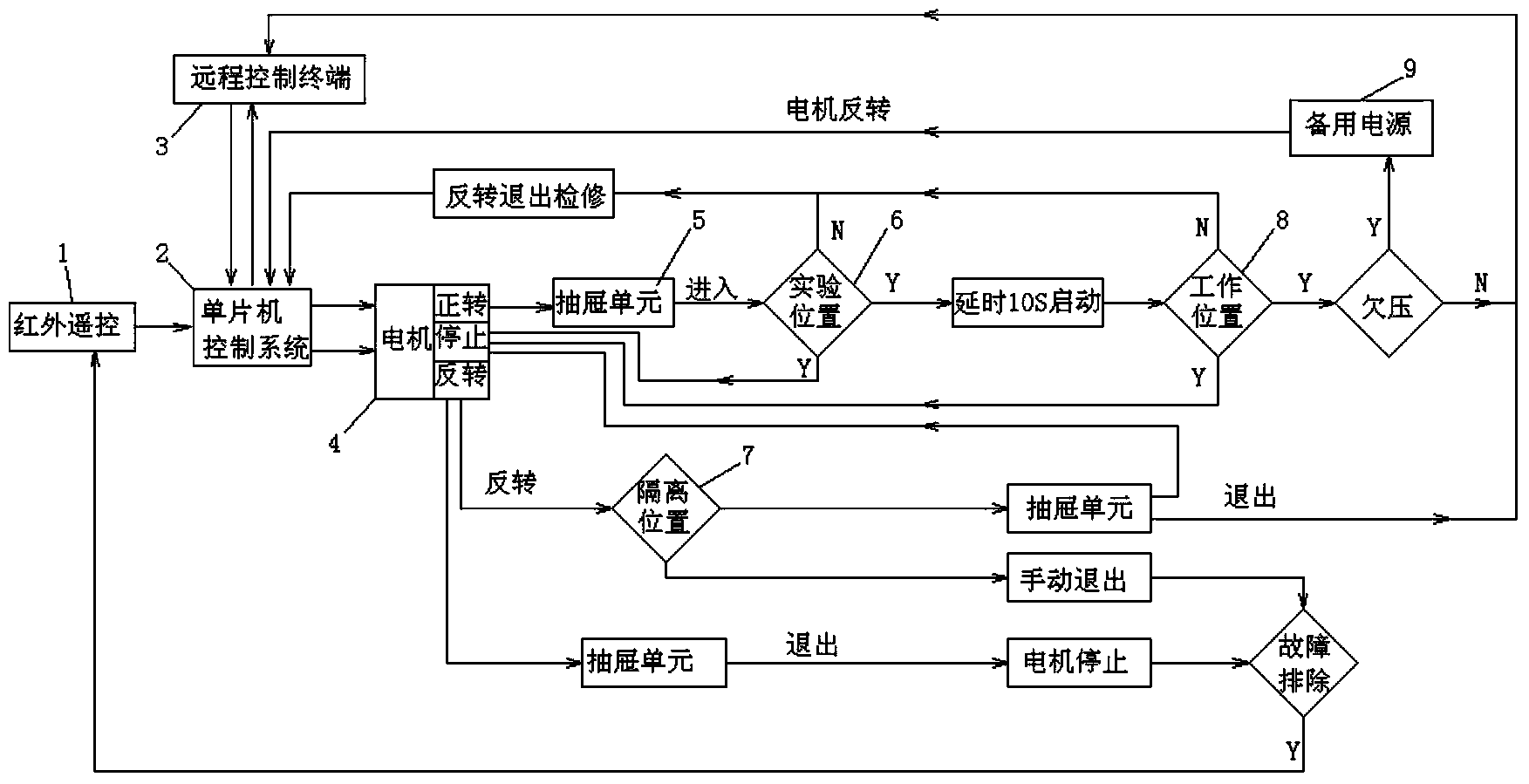

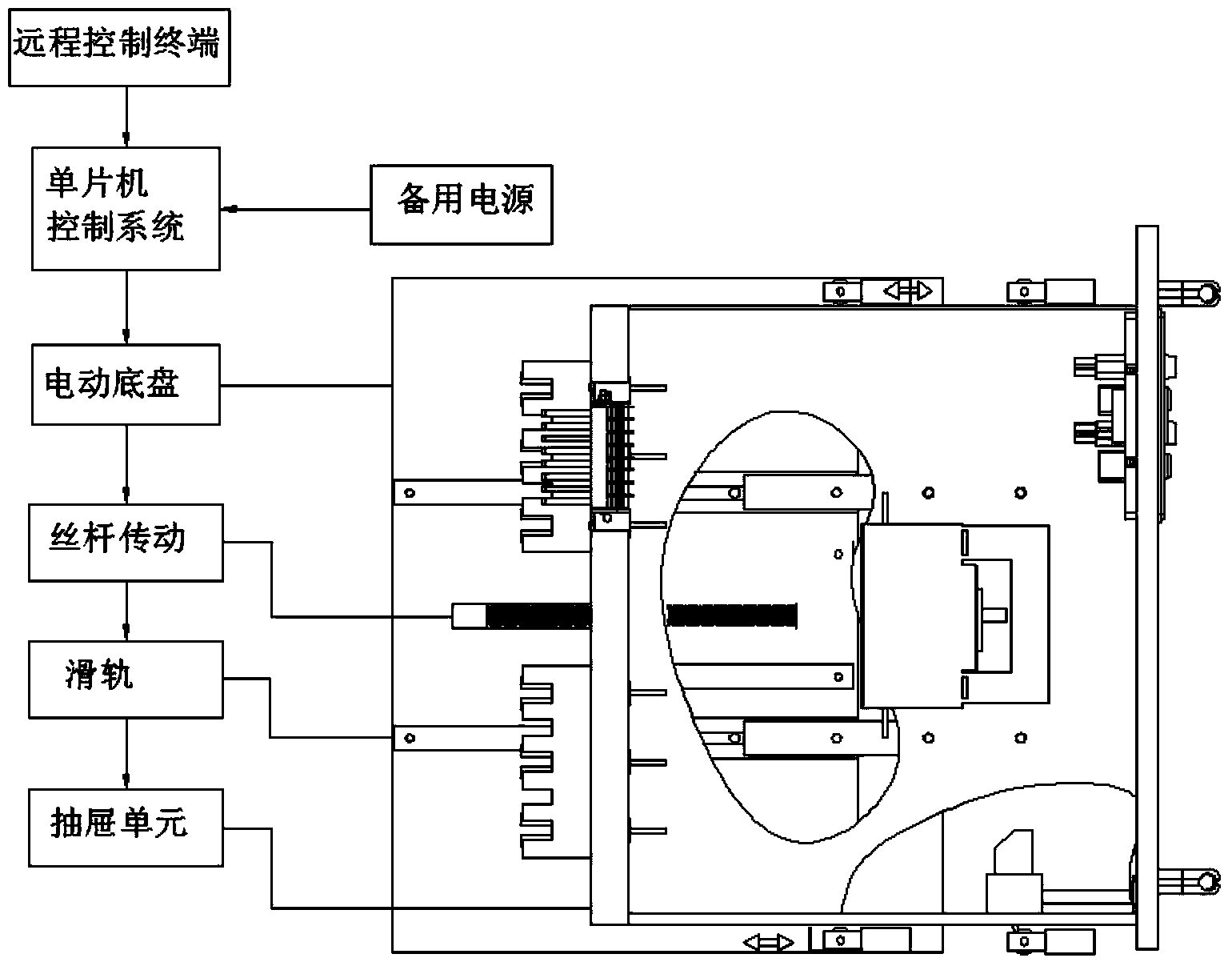

[0024] see figure 2 , an intelligent low-voltage drawer unit system control method, specifically comprising the following steps:

[0025] (1), first place the prepared drawer unit 5 in the original position, then send an instruction to the single-chip microcomputer control system 2 through the infrared remote control 1, and the single-chip microcomputer control system 2 sends a forward rotation command to the servo motor 4, and the servo motor 4 is running forward at this time. Turn, drive the drawer unit 5 into the cabinet;

[0026] (2) After the drawer unit 5 enters the cabinet, when the test position 6 of the circuit breaker is correct, the servo motor 4 stops forward rotation, and after a delay of 10 seconds through the relay, the servo motor 4 continues to rotate forward, driving the drawer unit 5 into the cabinet. working position, and close the circuit breaker to the working position;

[0027] (3) After the drawer unit 5 reaches the working position, when the indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com