Comb tooth piece for weft-knitting computer jacquard cotton lace fabric and its production

A jacquard cotton and computer technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve problems such as increased yarn tension fluctuations, research and development of cotton-spandex fabrics that cannot be completely overcome, and cotton jacquards that are difficult to weave efficiently. Achieve the effects of reducing tension fluctuations, broad market application prospects, and improving comfort and fit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

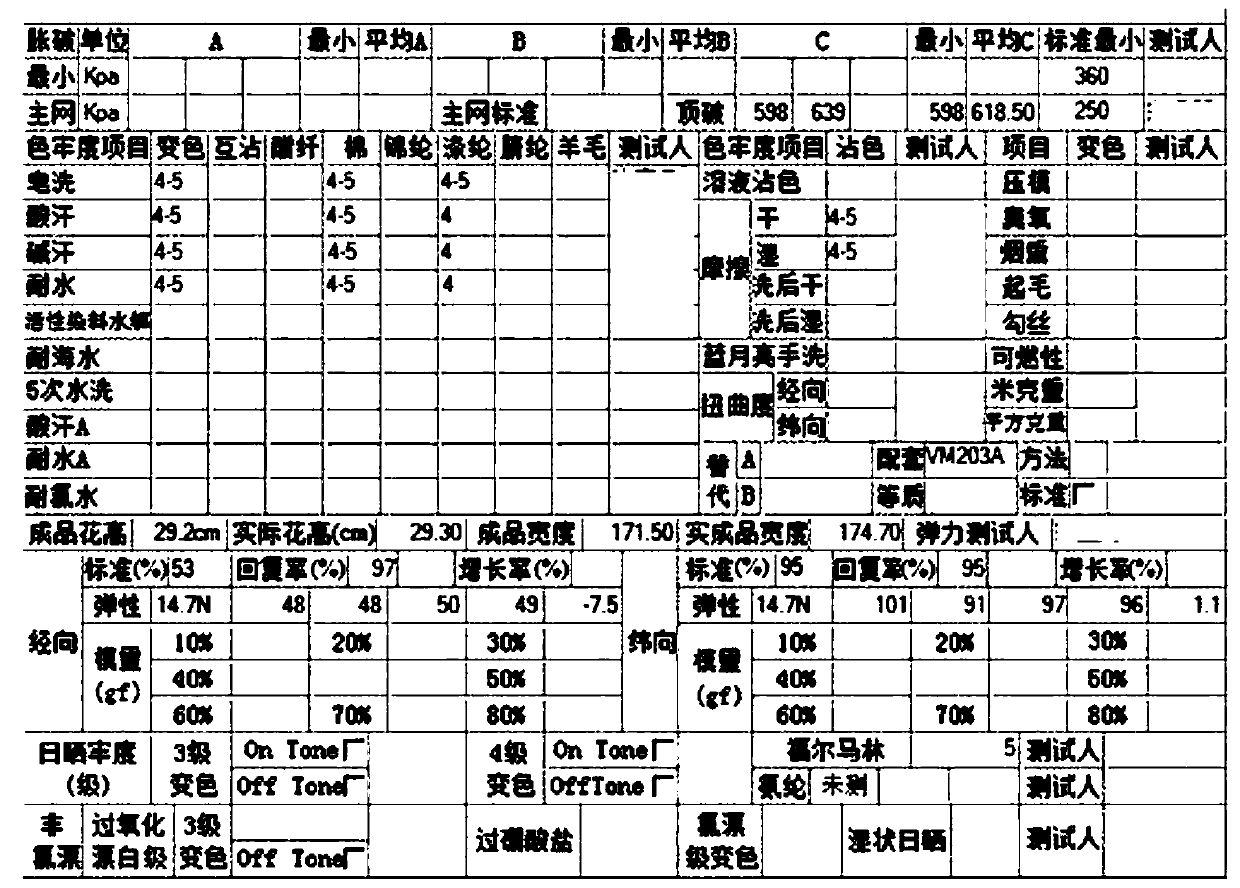

[0025] The invention provides a cotton lace fabric for weft knitting computer jacquard, comprising the same number of spandex with a total fineness of 40D, nylon filaments of 30D and cotton yarn of 44D, the number of which is 50-55, Preferably 54, see figure 1 , Finished product physical performance index test table, as can be seen from Table 1, this fabric has superior physical properties.

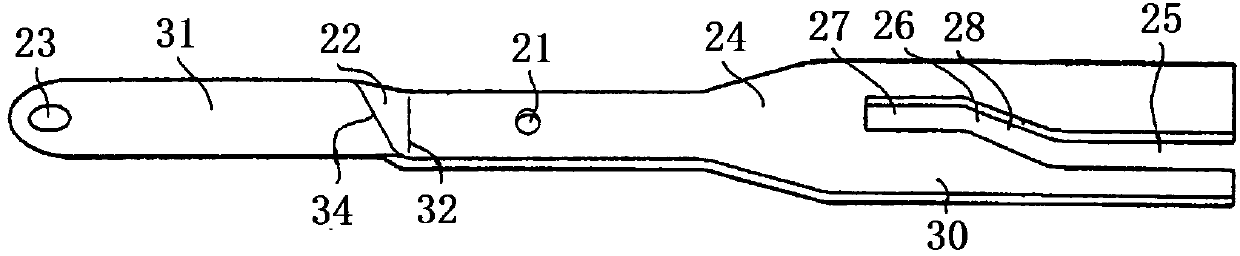

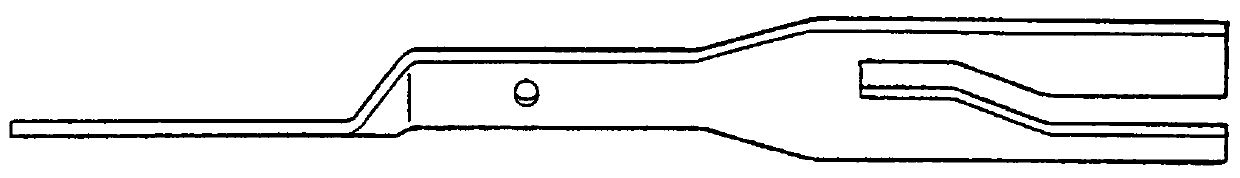

[0026] Such as Figure 2 to Figure 5 As shown, the comb tooth piece used for the production of weft-knitted computer jacquard cotton lace fabrics according to the present invention includes the first slat 30, the middle transition slat 24, the deflection triangle 22 and the second slat 31, the One end of the intermediate transition slat 24 is connected with the first slat 30, and the other end of the intermediate transition slat 24 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com