Nanoscale precision piezoelectric driving linear displacement table

A piezoelectric drive, linear displacement technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. friction surface wear and other problems, to achieve the effect of ingenious structural design, conducive to wide popularization and application, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

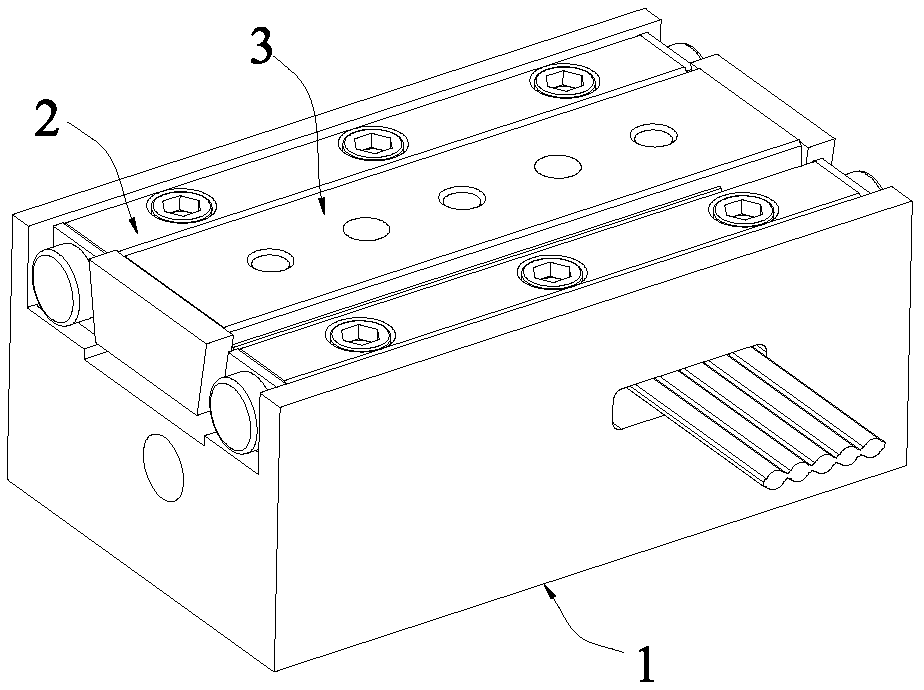

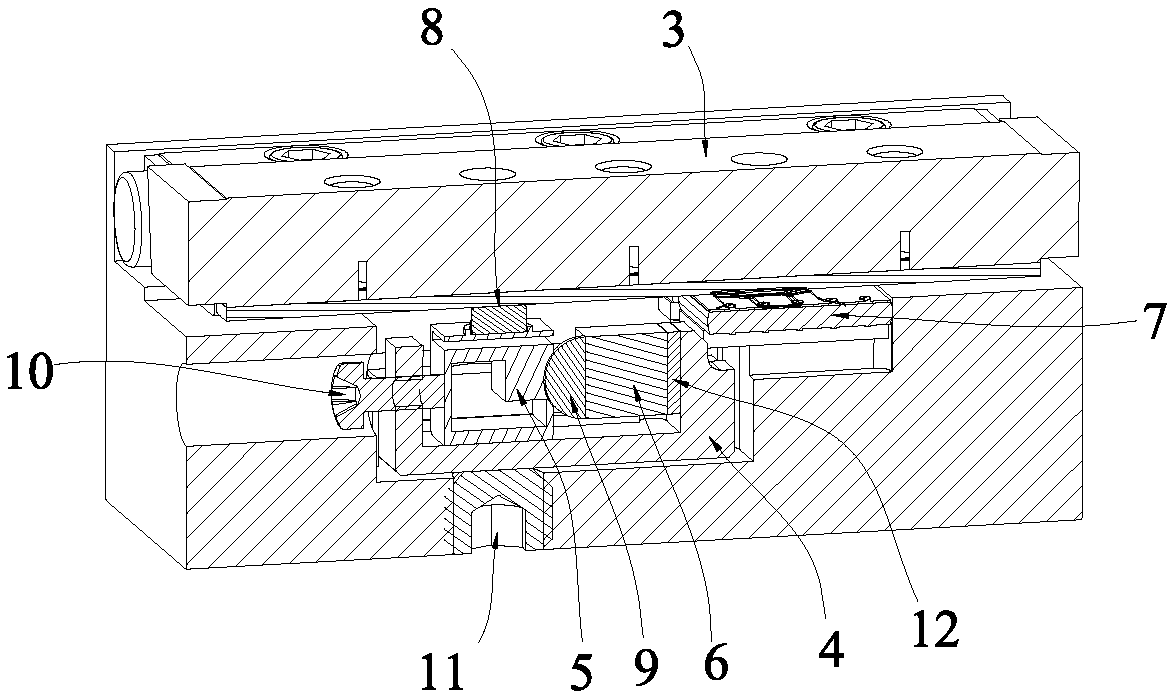

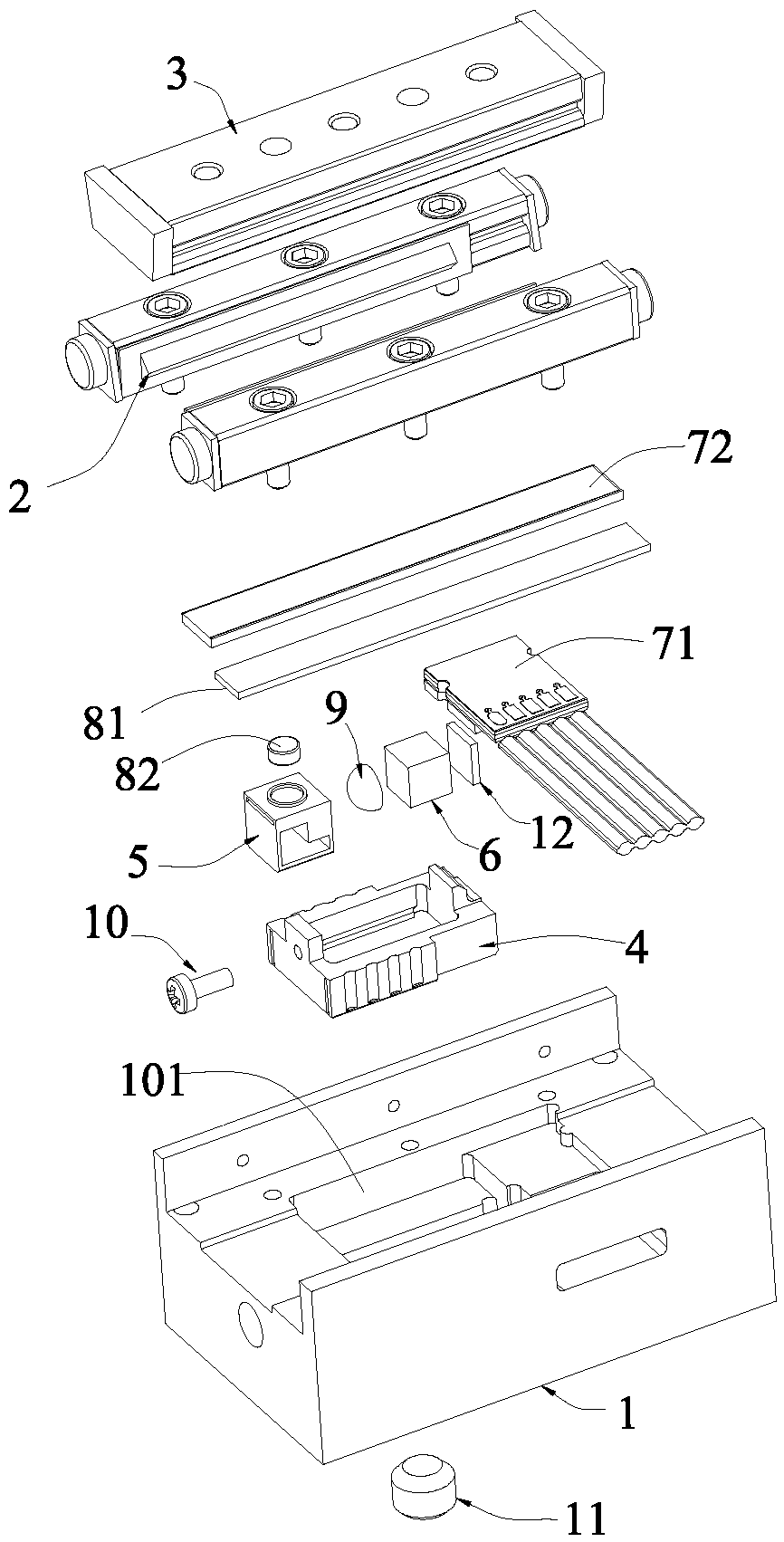

[0024] see Figure 1 to Figure 6 , a nano-scale precision piezoelectric driven linear displacement stage provided in this embodiment, which includes a substrate 1, a slide rail 3 that is movably arranged on the substrate 1 through a sliding assembly 2, a driving base 4, a flexible mass 5, a piezoelectric A drive unit 6 , a position sensor unit 7 and a stick-slip friction assembly 8 . The stick-slip friction assembly 8 includes an upper wear-resistant sheet 81 and a lower wear-resistant sheet 82 .

[0025] The driving seat 4 is arranged in the base body 1, specifically, the base body 1 is provided with a driving chamber 101 for installing the driving seat 4, and the driving seat 4 is located in the driving chamber 101. The outer wall of 4 is provided with a glue filling groove 41, and the inner position corresponding to the glue filling groove 41 is provided with a guide channel 42 through which the driving seat 4 penetrates. Hinge. The glue filling groove 41 is filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com