Hydraulic mechanism for vehicle

A hydraulic mechanism and hydraulic technology, applied in the direction of hydraulic brake transmission, mechanical equipment, non-mechanical drive clutch, etc., can solve the problem of occupying vehicle space, achieve the effect of improving precision, realizing miniaturization, and improving carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

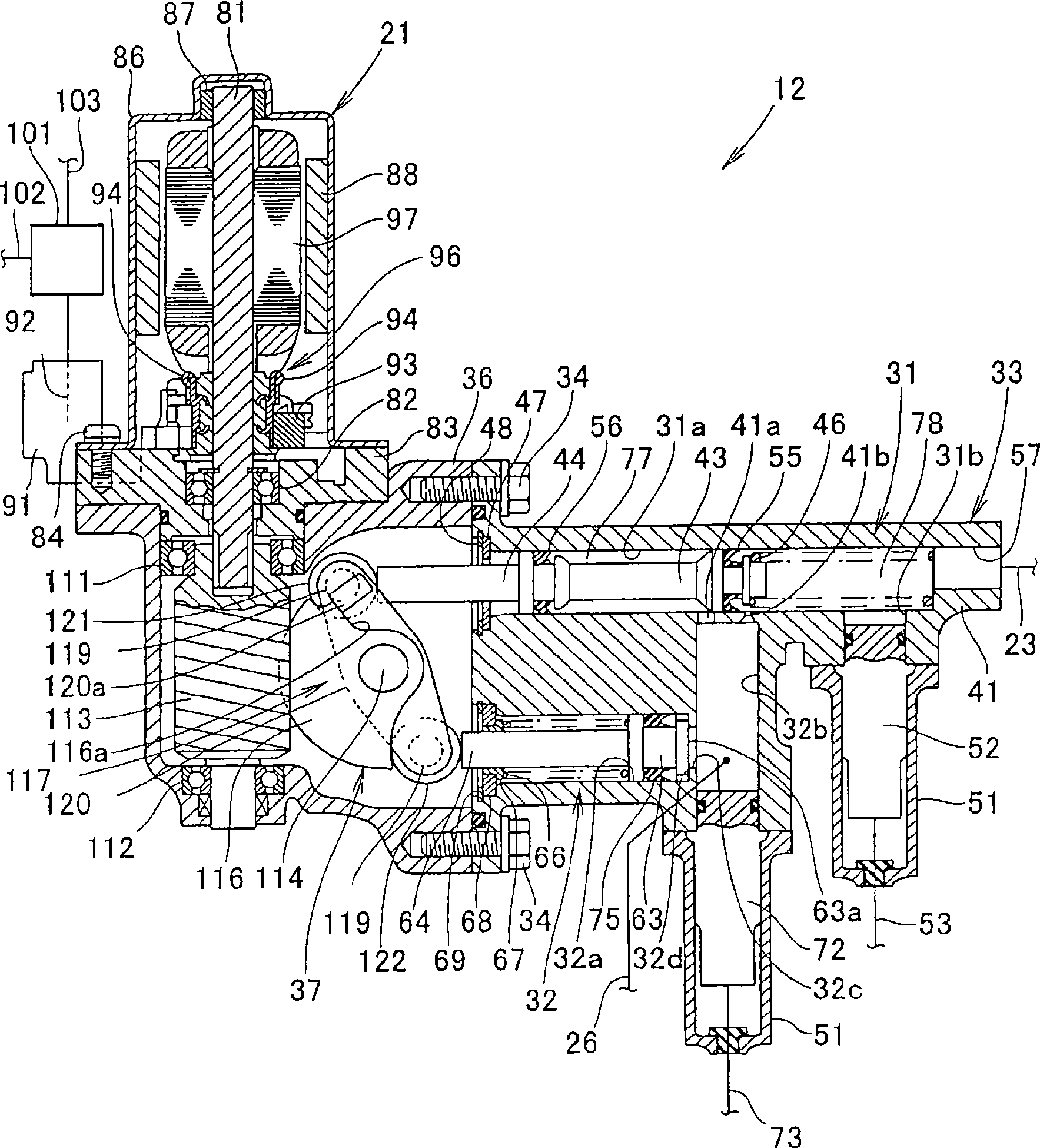

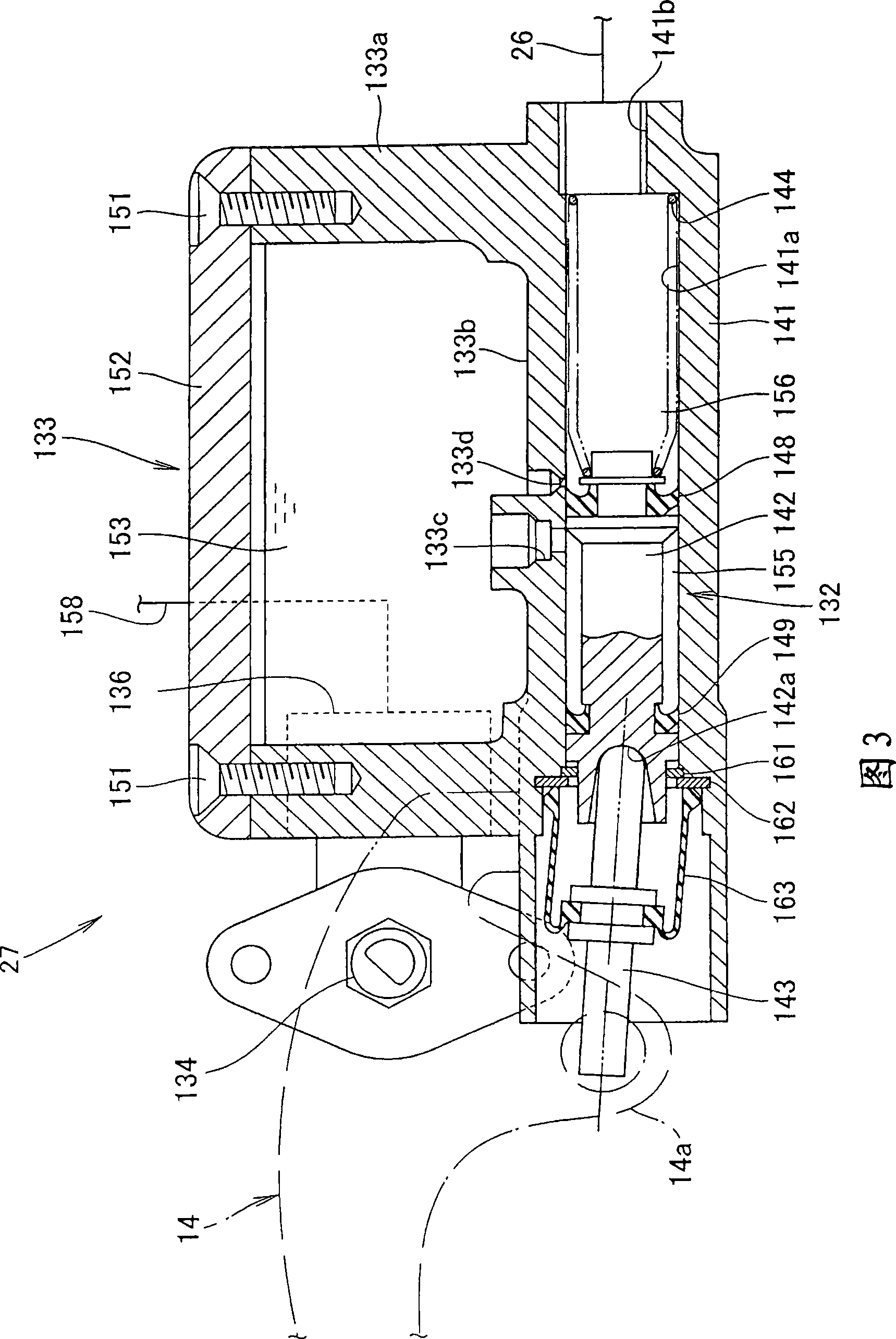

[0064] The best mode for carrying out the present invention will be described below with reference to the drawings. In addition, look at the picture according to the direction of the symbol.

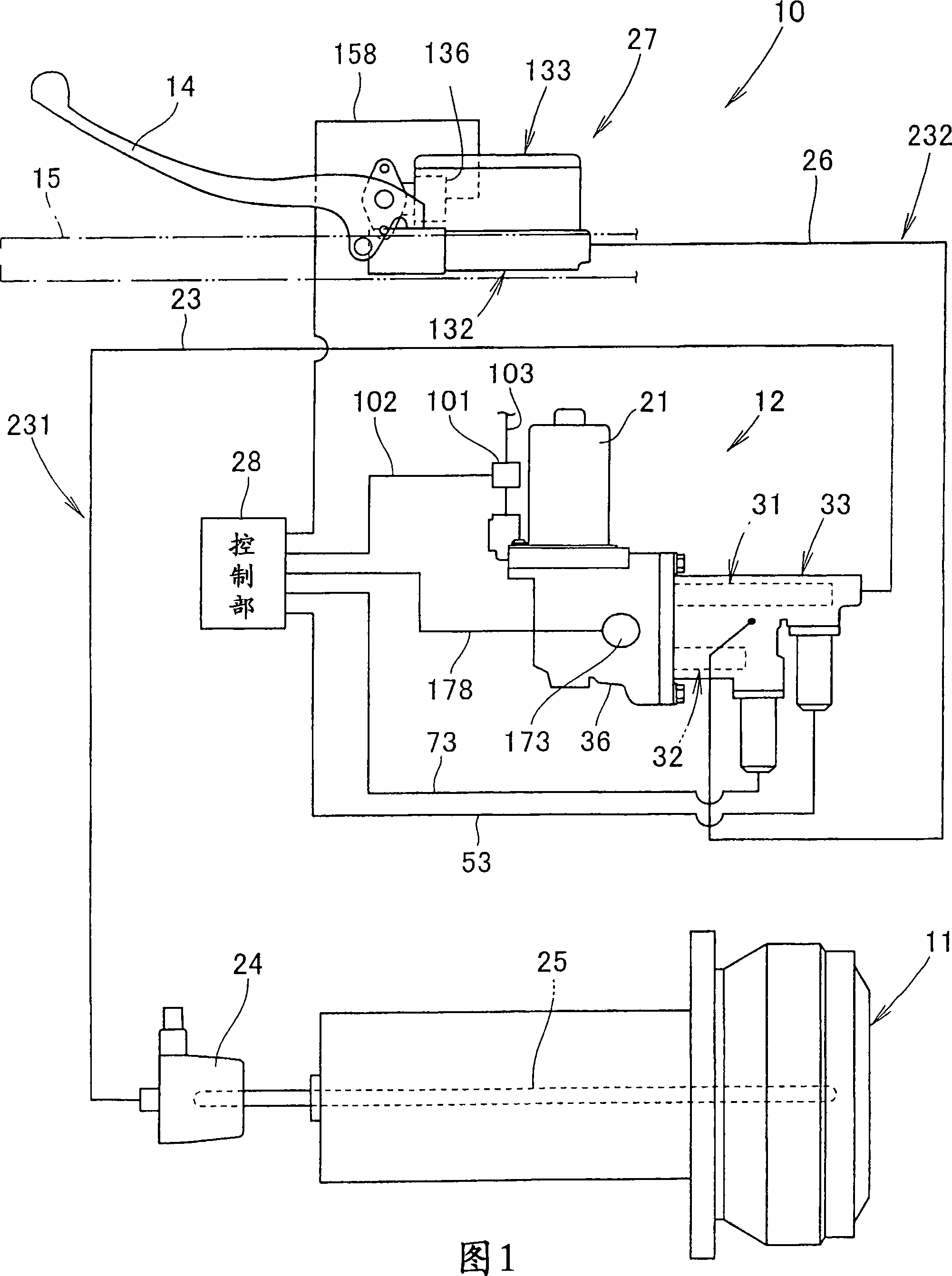

[0065] 1 is a system diagram showing a clutch hydraulic mechanism for a vehicle according to the present invention. When a clutch hydraulic mechanism 10 utilizes a clutch 11 to transmit and disconnect power between an engine and a transmission of a saddle-type vehicle such as a motorcycle or an off-road vehicle, Usually detect the stepping force and vehicle speed of the gear shifting pedal. In the case of gear shifting, for example, the clutch 11 can be automatically disconnected (that is, disconnected or connected) by the actuator unit 12, and the clutch 11 can be manually disconnected or connected by the clutch lever 14 as required.

[0066] The clutch hydraulic mechanism 10 includes an actuator unit 12, a first release cylinder 24, a push rod 25, a rod operating portion 27, and a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com