Electro-hydraulic comprehensive-control type clutch

A comprehensive control and clutch technology, which is applied in the direction of clutches, non-mechanical drive clutches, mechanical equipment, etc., can solve the problems of reduced service life of drive train components, reduced life, reduced contact area of friction plates, etc., and achieves simple installation, manufacturing and processing. The effect of reducing the processing accuracy and reducing the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

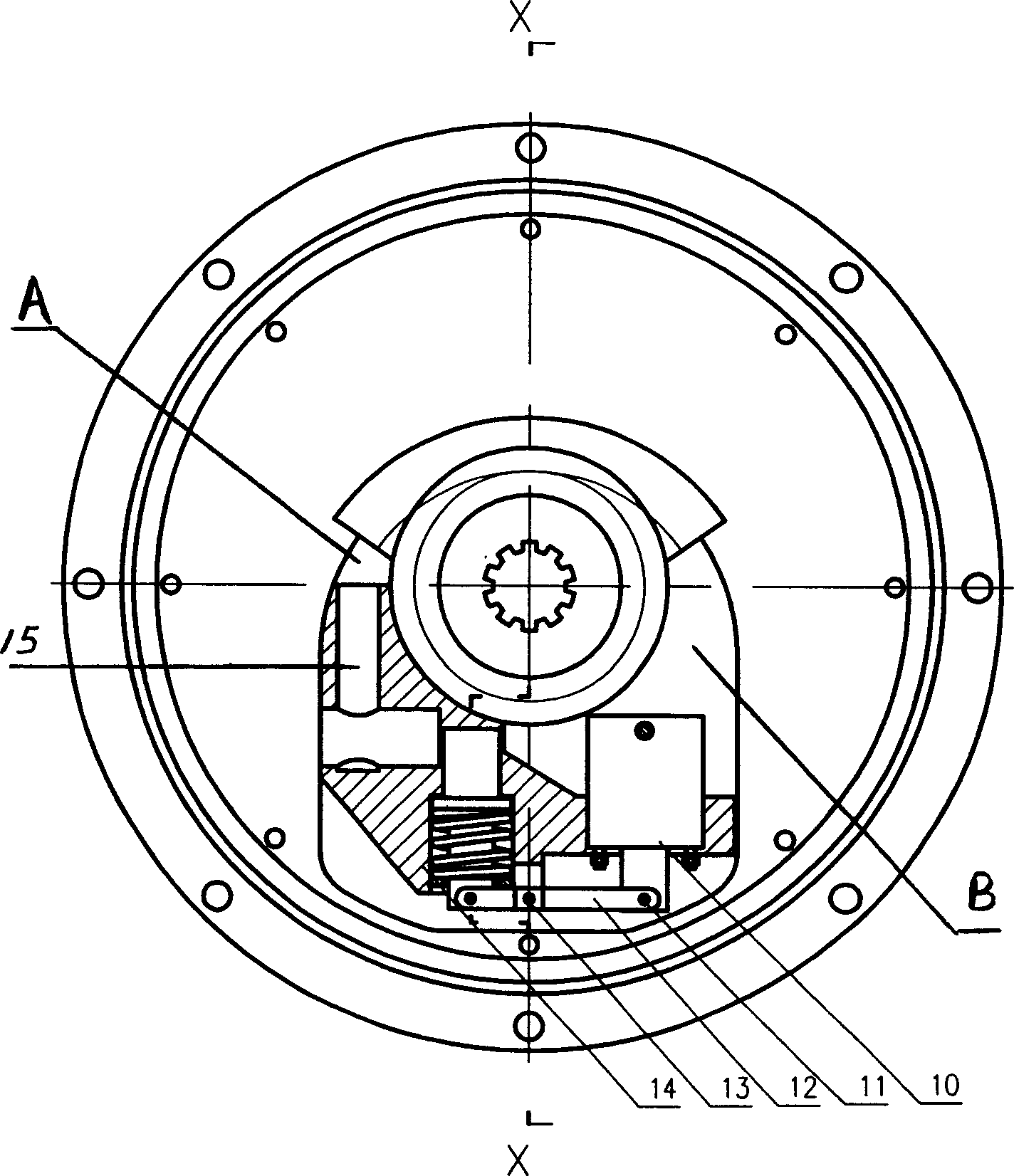

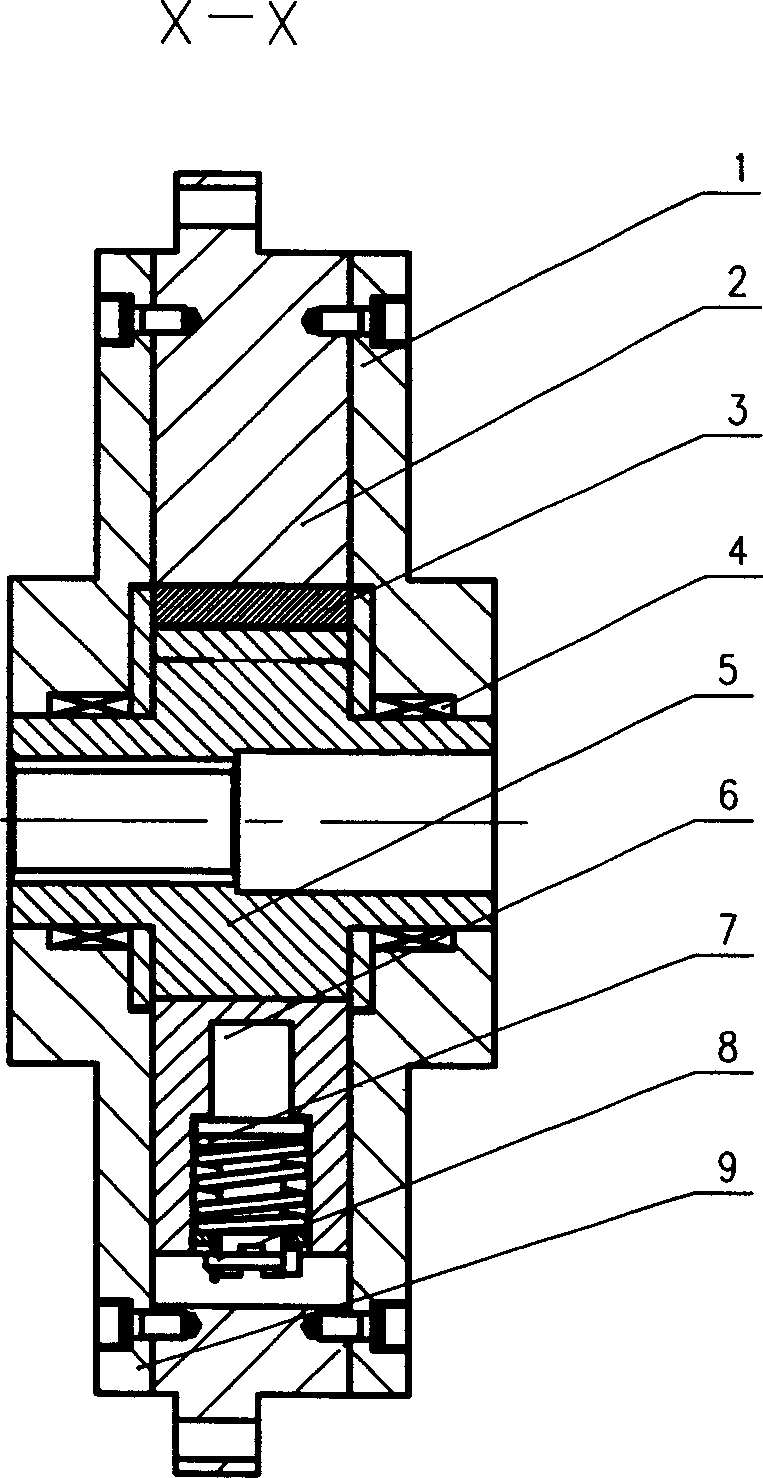

[0029] working principle:

[0030] The so-called electro-hydraulic integrated control clutch: it is to use the ring gear connected to the crankshaft of the engine to rotate together with the gear connected to the first shaft of the gearbox to form a pair of meshing gear pumps. A crescent block is added to the internal meshing gear pump to form an oil passage connecting the high and low pressure oil chambers of the gear pump. Electricity is used to control the opening and disconnection of the hydraulic oil circuit generated by the gear pump, and to control the inner ring gear and the oil passage. The relative rotation of the gears meshing with it realizes the transmission and interruption of power.

[0031] work process:

[0032] The up and down position of the cut-off valve 6 is controlled by the on and off of the electromagnet 10, which is used to control the on and off of the circuit between the high and low pressure oil chambers, that is, to realize the separation and comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com