Motor-driven hydraulic clutch and automobile

A hydraulic clutch and motor-driven technology, which is applied in the direction of non-mechanical drive clutches, clutches, mechanical equipment, etc., can solve problems affecting driving safety, operator fatigue, etc., and achieve the effects of compact structure, high reliability, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

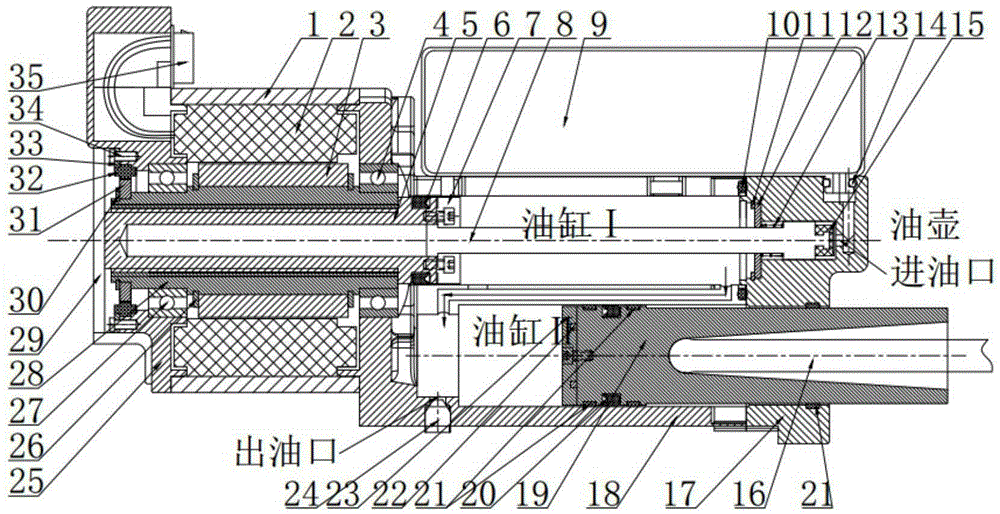

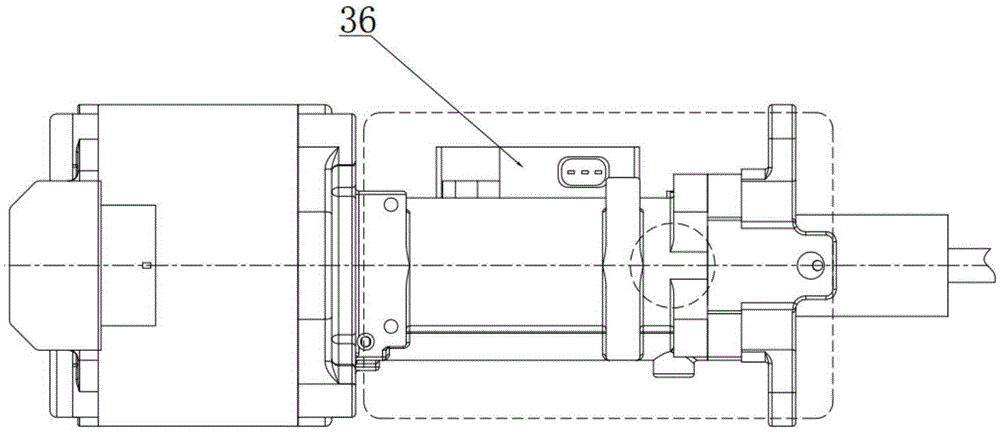

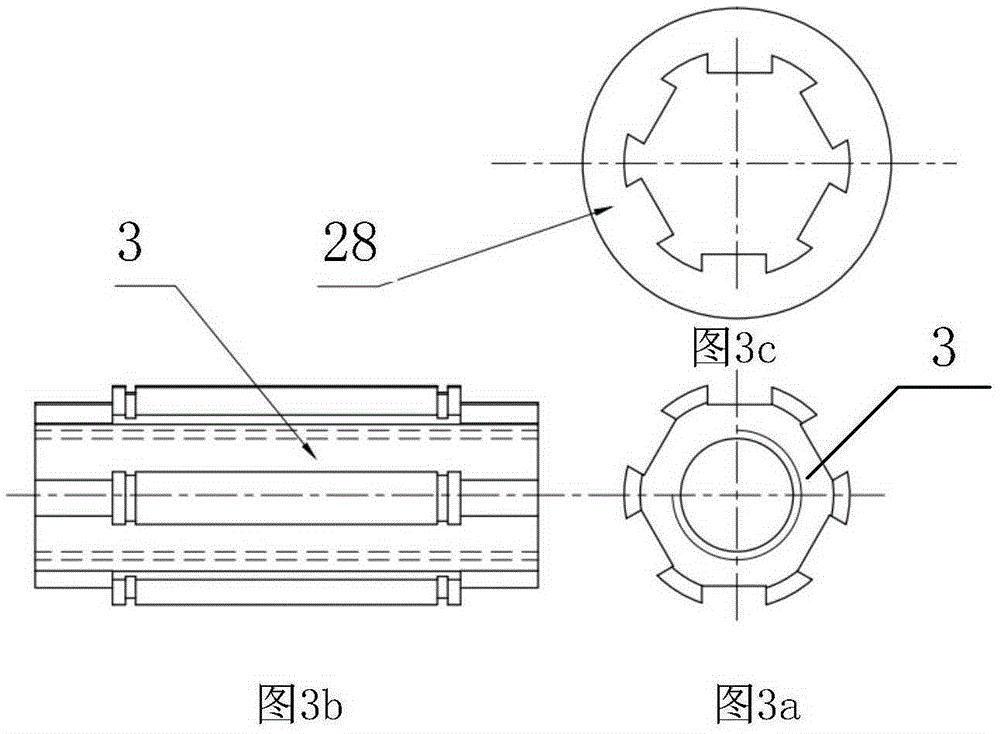

[0054] The invention provides a motor-driven hydraulic clutch, the structural diagram of which is as follows figure 1 and figure 2 shown, including:

[0055] Motor housing 1, motor stator coil 2, motor rotor 3, first deep groove ball bearing 4, trapezoidal screw rod 5, first hydraulic sealing ring 6, anti-rotation block 7, anti-rotation square rod 8, oil pot 9, The first O-ring 10, the first circlip 11, the retainer 12, the spring 13, the second O-ring 14, the cup 15, the clutch push rod 16, the cylinder end cover 17, the cylinder 18, the piston 19, the first Two hydraulic sealing rings 20, wear-resistant rings 21, displacement sensor magnetic rings 22, magnetic ring holders 23, plugs 24, motor rear end covers 25, second circlips 26, second deep groove ball bearings 27, trapezoidal screw rods Nut 28, rear end cover 29, fixed plate 30, resolver rotor 31, resolver stator 32, stator pressing piece 33, screw 34, connector 35 and displacement sensor 36.

[0056] The connection ...

Embodiment 2

[0081] The invention provides an automobile with a motor-driven hydraulic clutch. The automobile includes the above-mentioned motor-driven hydraulic clutch. The motor-driven hydraulic clutch is arranged between the engine and the gearbox to cut off or transmit the power transmitted from the engine to the gearbox.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com