Safety Clutch

A technology of safety clutches and suction discs, applied in clutches, non-mechanical drive clutches, mechanical equipment, etc., can solve problems such as large impact force, reduced gear train life, engine gear train failure, etc., achieve high cooling capacity and ensure normal operation The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not used to limit the present invention.

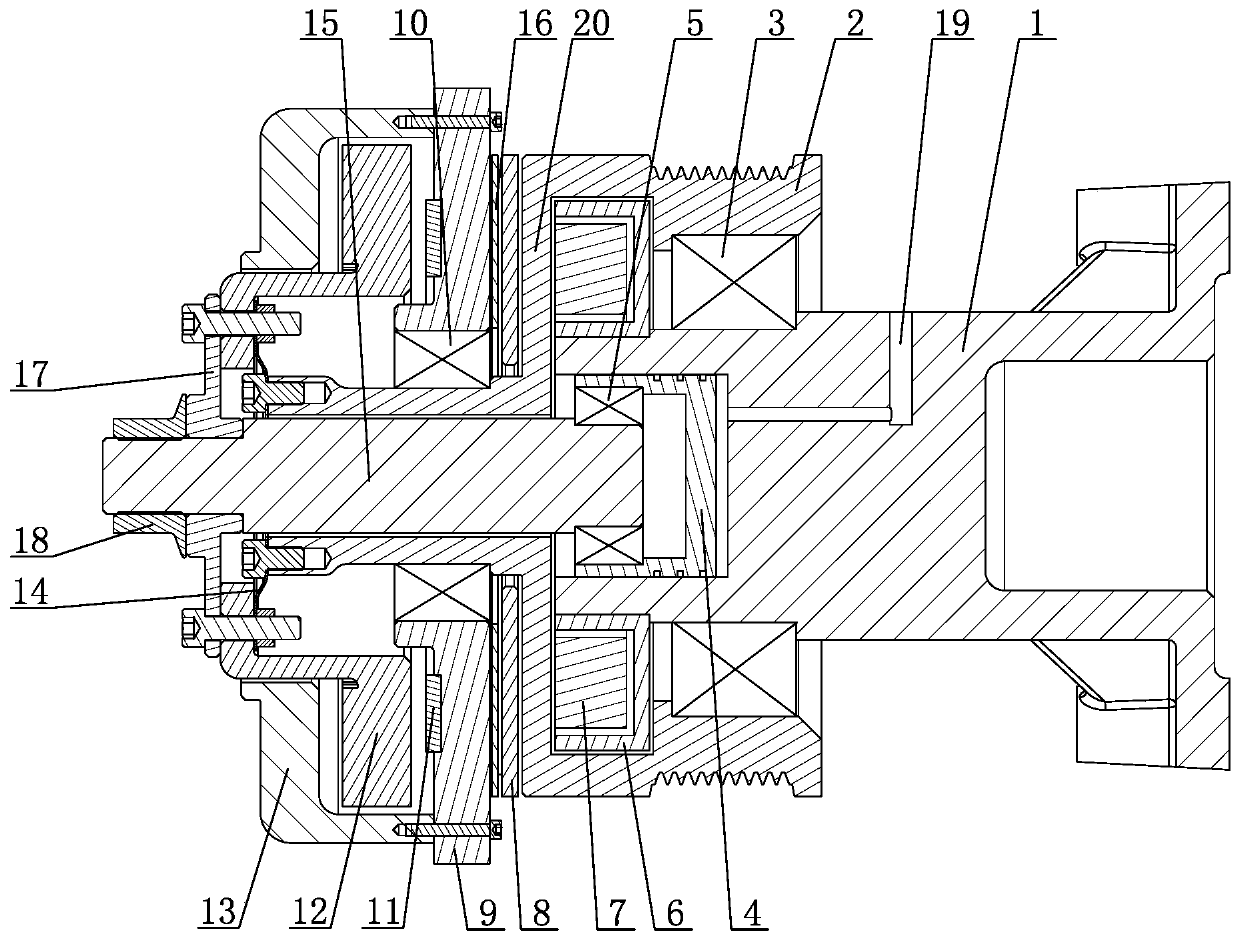

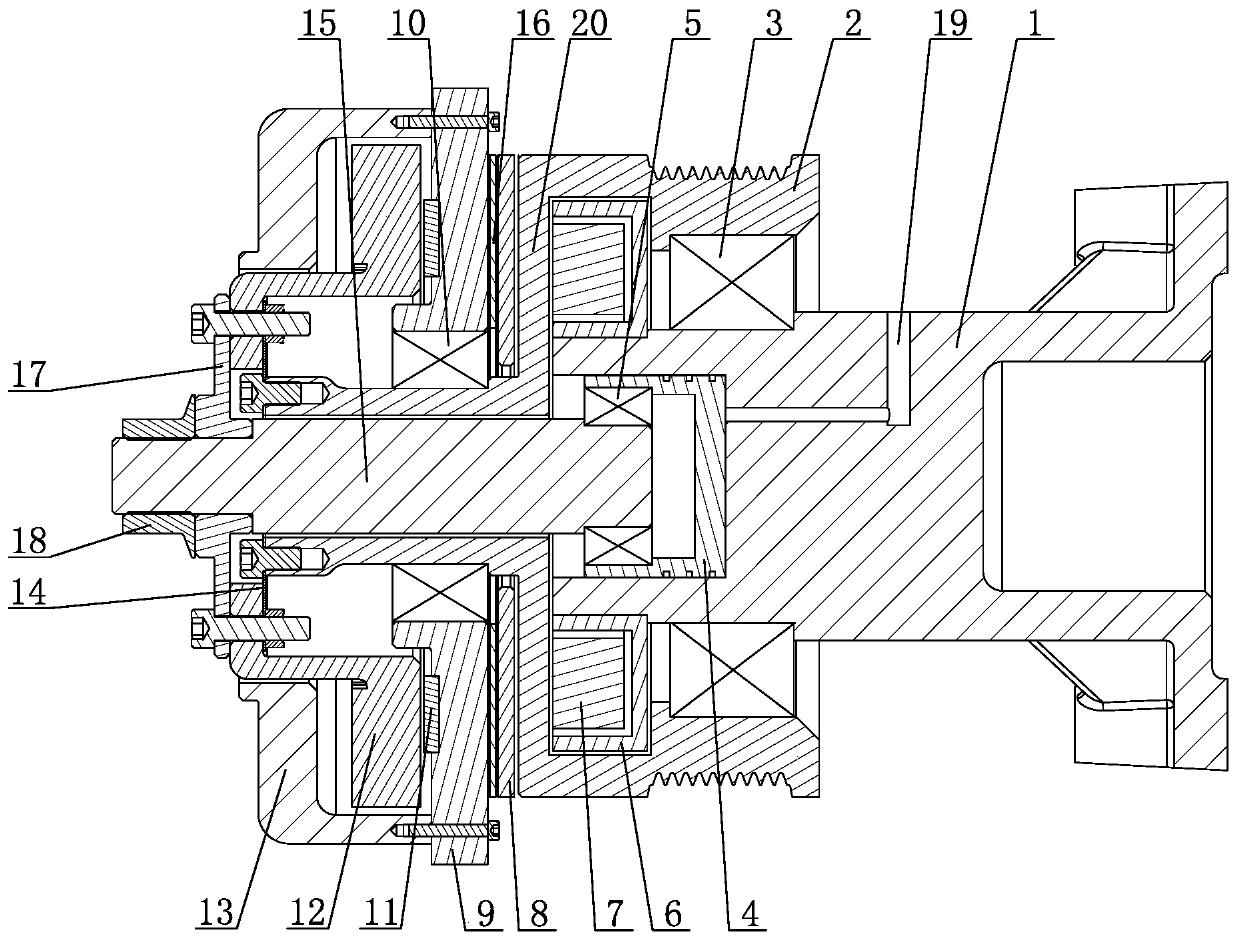

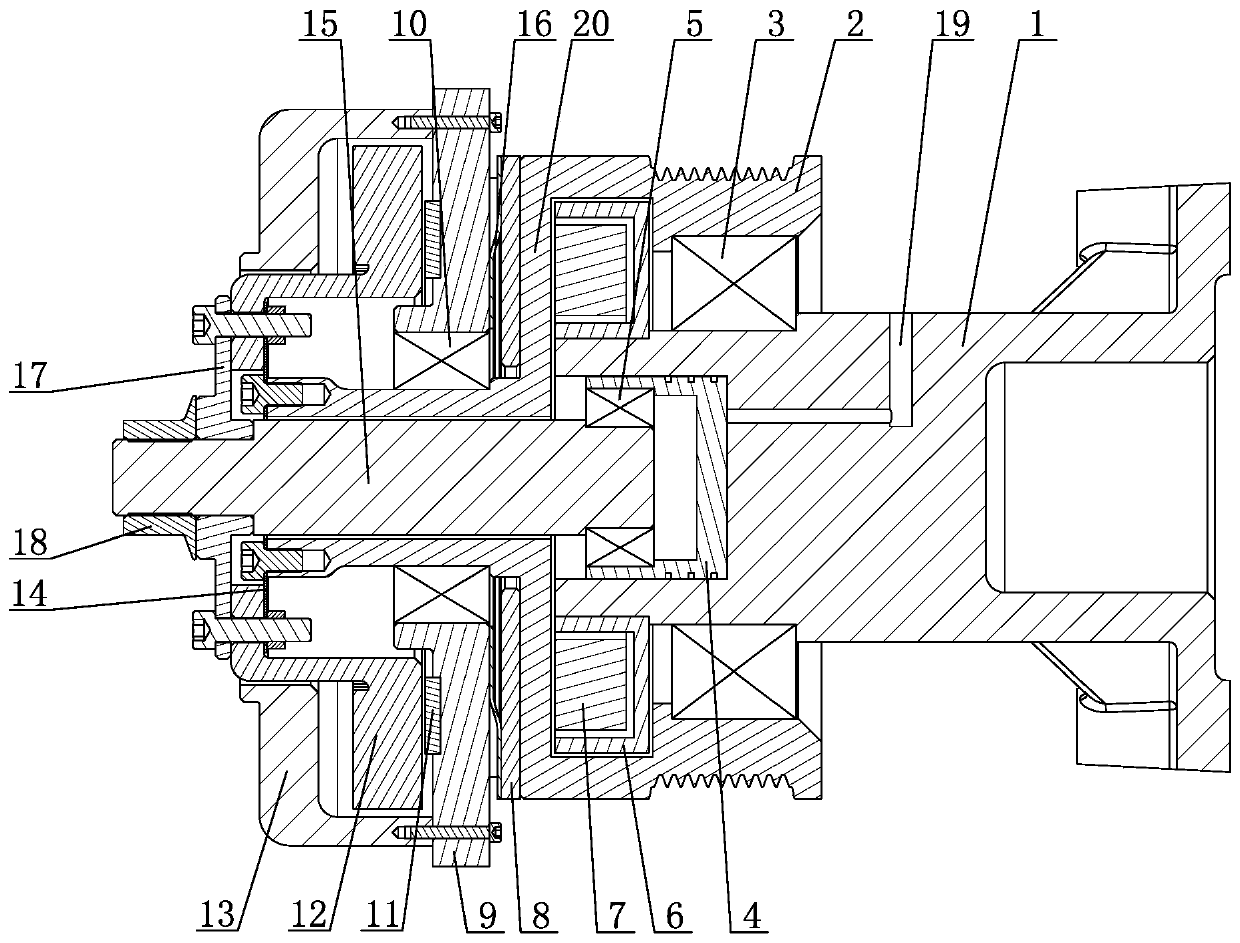

[0021] Such as figure 1 , figure 2 with image 3 As shown together, a safety clutch includes: a bracket 1, a pulley 2, a drive shaft 15, a permanent magnet 11, a coil 7, an iron core 6, a fan fixing plate 13, a cooling plate 12 and a rear cover 9. The pulley 2 passes through a bearing 3 Rotatingly mounted on the bracket 1, the belt pulley 2 is fixedly provided with a transmission disk 20, one side of the transmission disk 20 is provided with a coil 7 and an iron core 6, the iron core 6 is fixed on the outside of the coil 7, and the iron core 6 is fixed on the bracket 1. The other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com