General frame system for automobile exterior verification model

A technology for verifying models and skeletons, applied in the field of automobile manufacturing, can solve the problems of increasing engineering design time, increasing manpower, and consuming manpower, and achieving the effect of reducing engineering design time, reducing welding time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

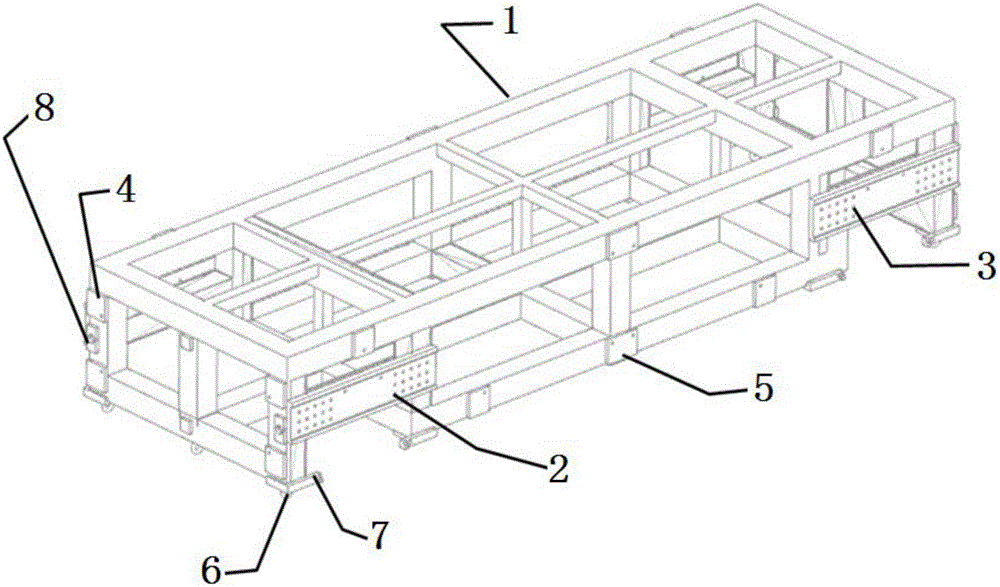

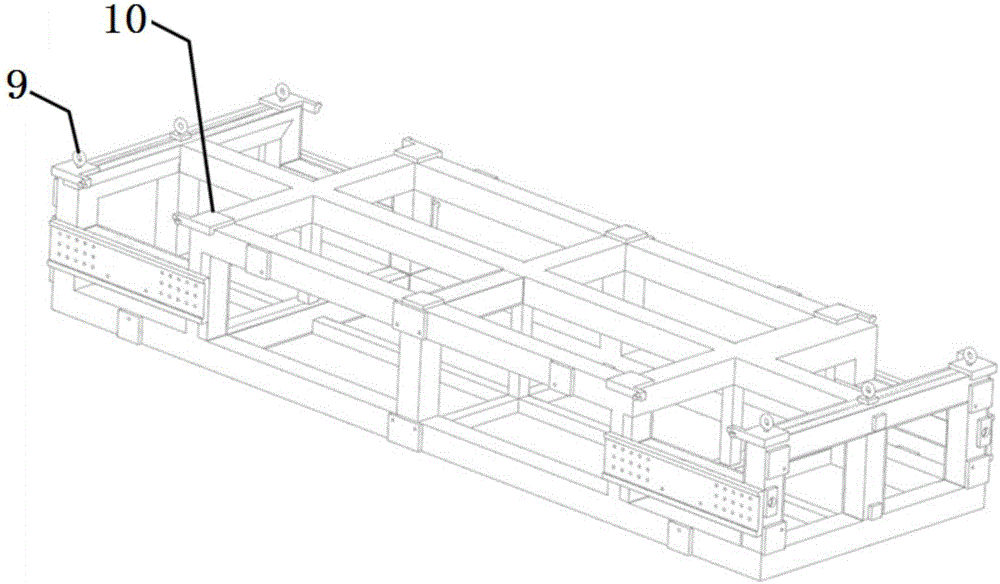

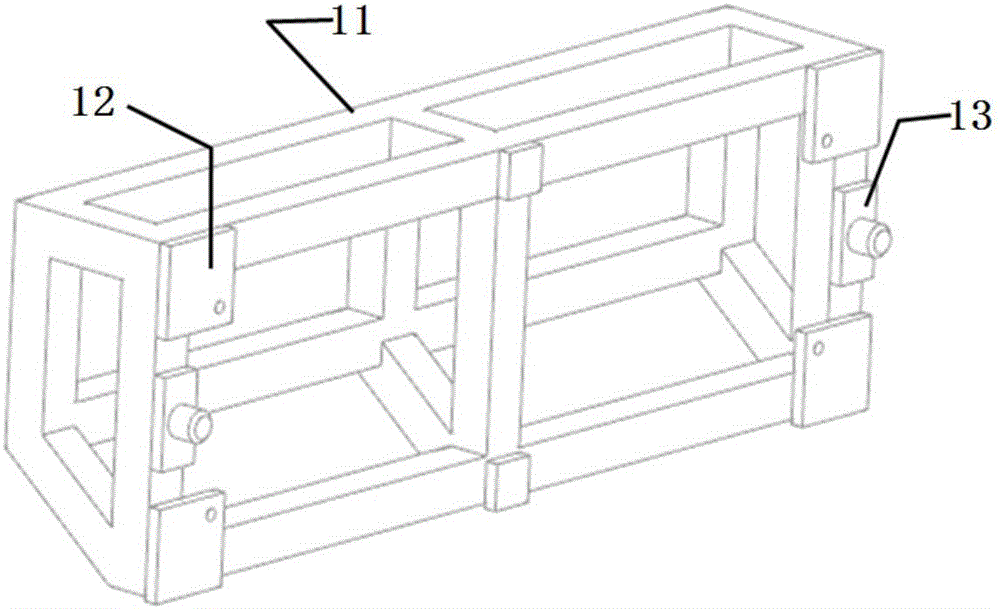

[0055] Such as Figure 1-8 Shown, a kind of general frame system that is used for the verification model of automobile exterior decoration, this frame system comprises main frame, the front tire support 19 that is arranged on the front end of main frame and the front support frame 11, the rear tire support 20 that is arranged on the rear end of main frame And the rear protection frame 14, the left and right sides of the main frame are also respectively provided with a front wheel support locking adjustment panel 2 and a rear wheel support locking adjustment panel 3, and the front tire support 19 and the rear tire support 20 are locked and protected by the front wheel support respectively. The adjustment panel 2 and the rear wheel bracket locking adjustment panel 3 are laterally adjusted along the length direction of the main frame. The frame system also includes a pair of side frames 17 symmetrically arranged on the left and right sides of the main frame.

[0056] Wherein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com