Method for producing a magnetic separation for a solenoid valve

A technology of magnetic valve and injection method, applied in the field of magnetic valve manufacturing, can solve problems such as limiting and limiting the efficiency of magnetic valve, and achieve the effects of avoiding thermal stretching, high tensile strength, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Identical components are always provided with the same reference numerals in different figures and are therefore usually only referred to or referred to only once in each case.

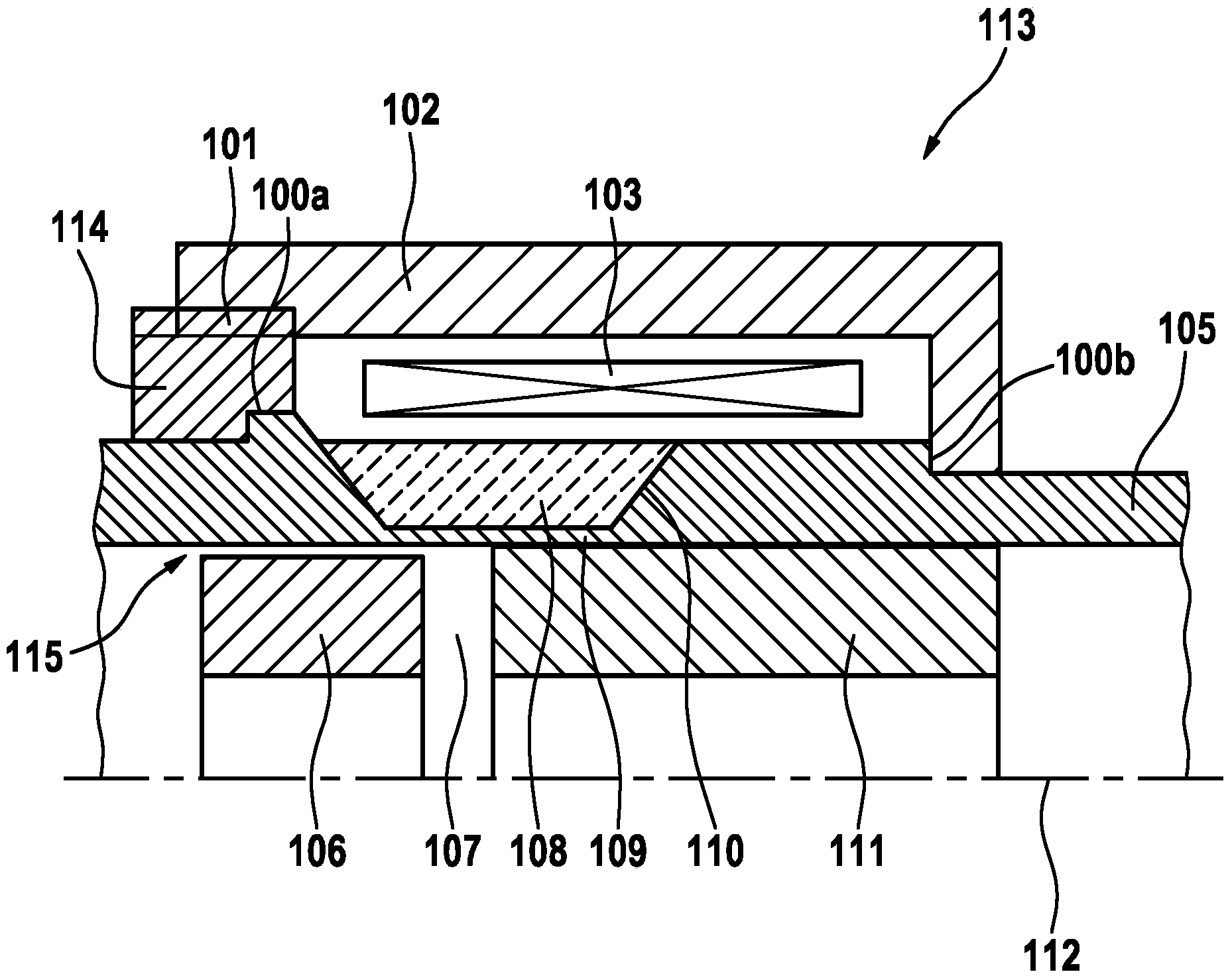

[0020] figure 1 A part of the solenoid valve 113 according to the first embodiment is shown schematically. Solenoid valve 113 is in particular an injection valve for fluid fuel (valve needle and return spring not shown). The solenoid valve is designed rotationally symmetrically about the axis 122 . An armature 106 (hereinafter also referred to as armature 106 ), which is soft-magnetic, that is to say made of ferromagnetic material, is mounted so that it can move axially and when coil 103 (hereinafter also referred to as electromagnetic coil 103 ) is switched on by Magnetic attraction caused by the soft magnetic inner pole 111 (hereinafter also referred to as the magnetic core 111 ). For high magnetic forces it is possible to ensure that the magnetic flow penetrates the armature air gap 107 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com