Method for producing a bearing ring, in particular for a tapered roller bearing

A tapered roller bearing and bearing ring technology, applied in the field of bearing rings, can solve problems such as high cost, achieve high dimensional stability, good repeatability, and eliminate the need for reprocessing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Provision is made in the first step of an exemplary implementation of the method according to the invention to provide a circular disk.

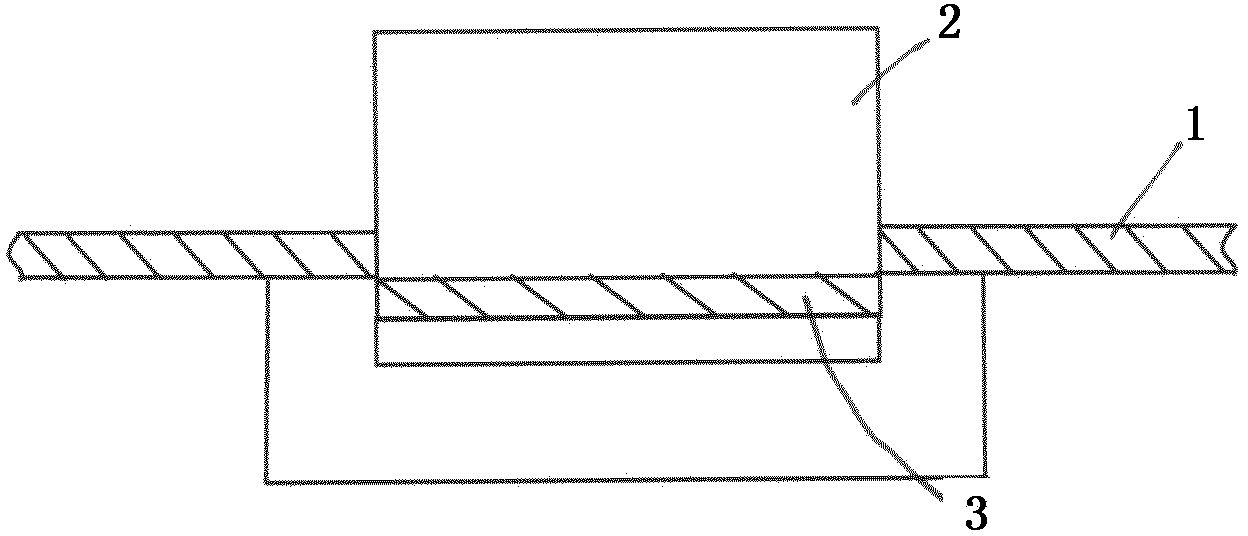

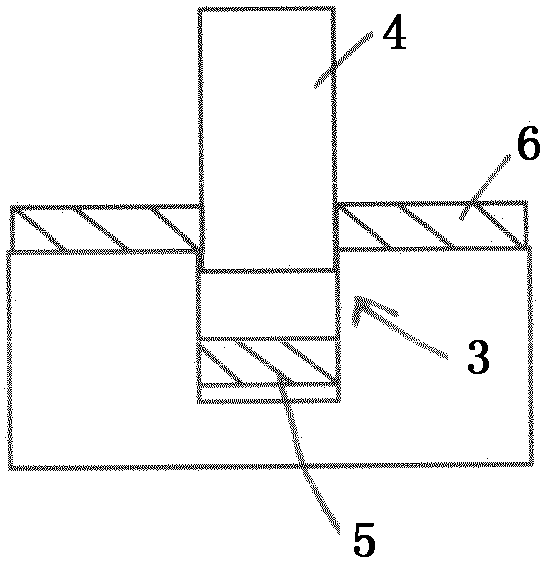

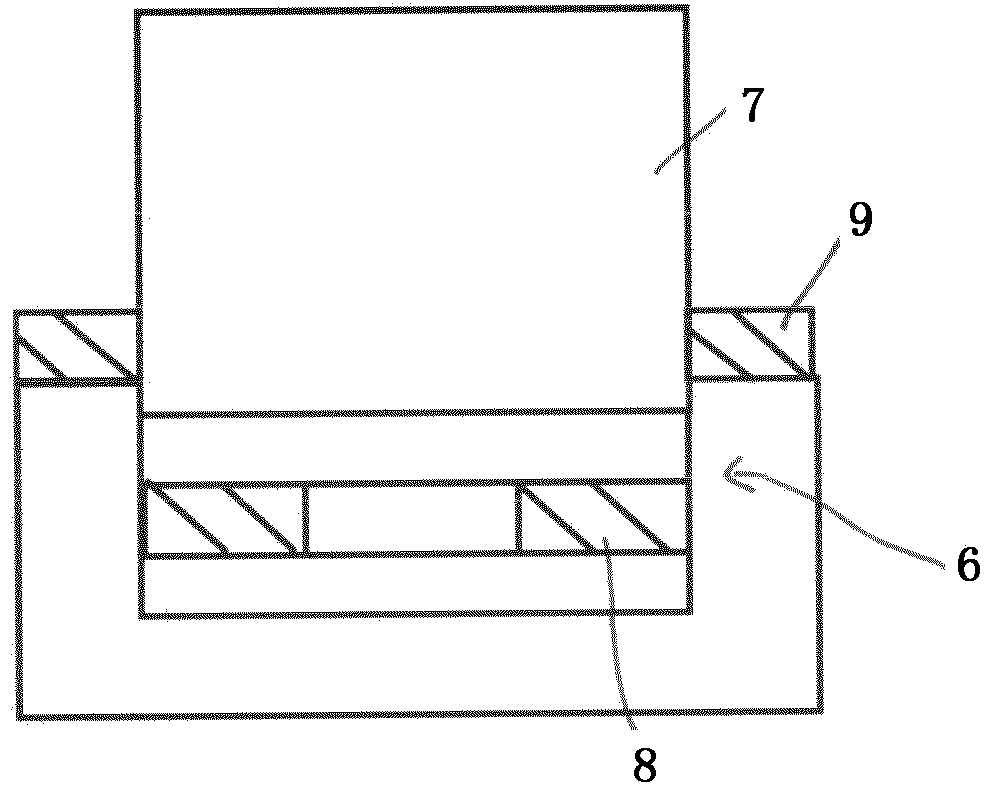

[0039] Figure 1 to Figure 3 Three preparatory steps are shown in succession for an exemplary execution of the method according to the invention, wherein a circular disk is produced and provided for the method according to the invention.

[0040] figure 1 A sheet metal 1 made of hardenable steel material is shown, which is arranged in a stamping tool 2 . In a first preparatory step, a disc blank 3 , ie a punched blank with a circular contour, is punched out of the sheet metal 1 .

[0041] figure 2 Shown is a disc blank 3 in which a central circle section 5 is stamped in a second stamping tool 4, so that a circular disc 6 is produced in a second preparatory step, i.e. has a circular outer contour and a circular shape. Segments of the inner contour.

[0042] image 3The circular disk 6 is shown in the third stamping die 7 , where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com