Mesoporous silica (SiO2) and preparation method thereof

A mesoporous silica and mesoporous technology, applied in the field of silica gel fillers, can solve the problems of complex preparation process, high cost, and increased production cost, and achieve the effect of simplifying the original process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

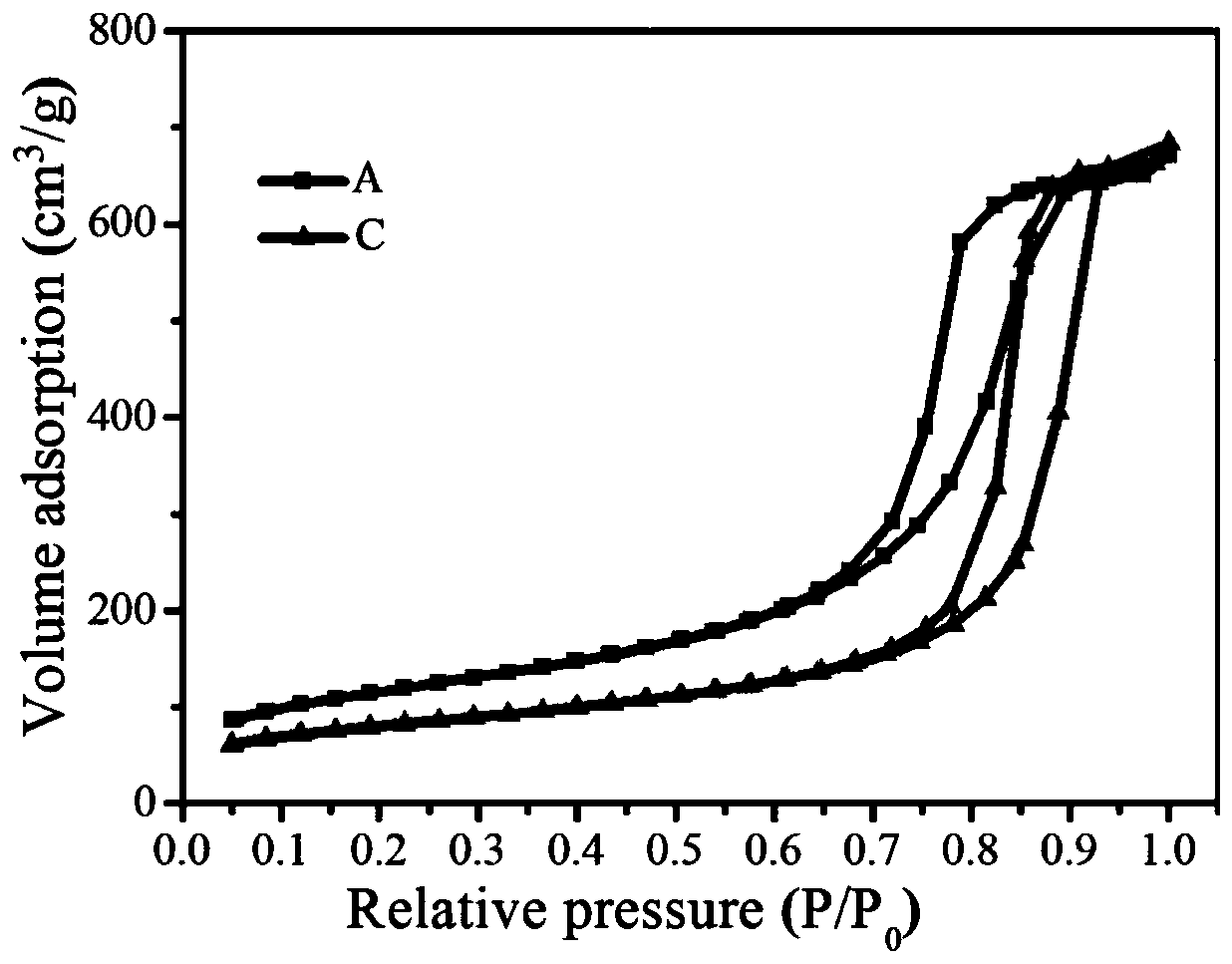

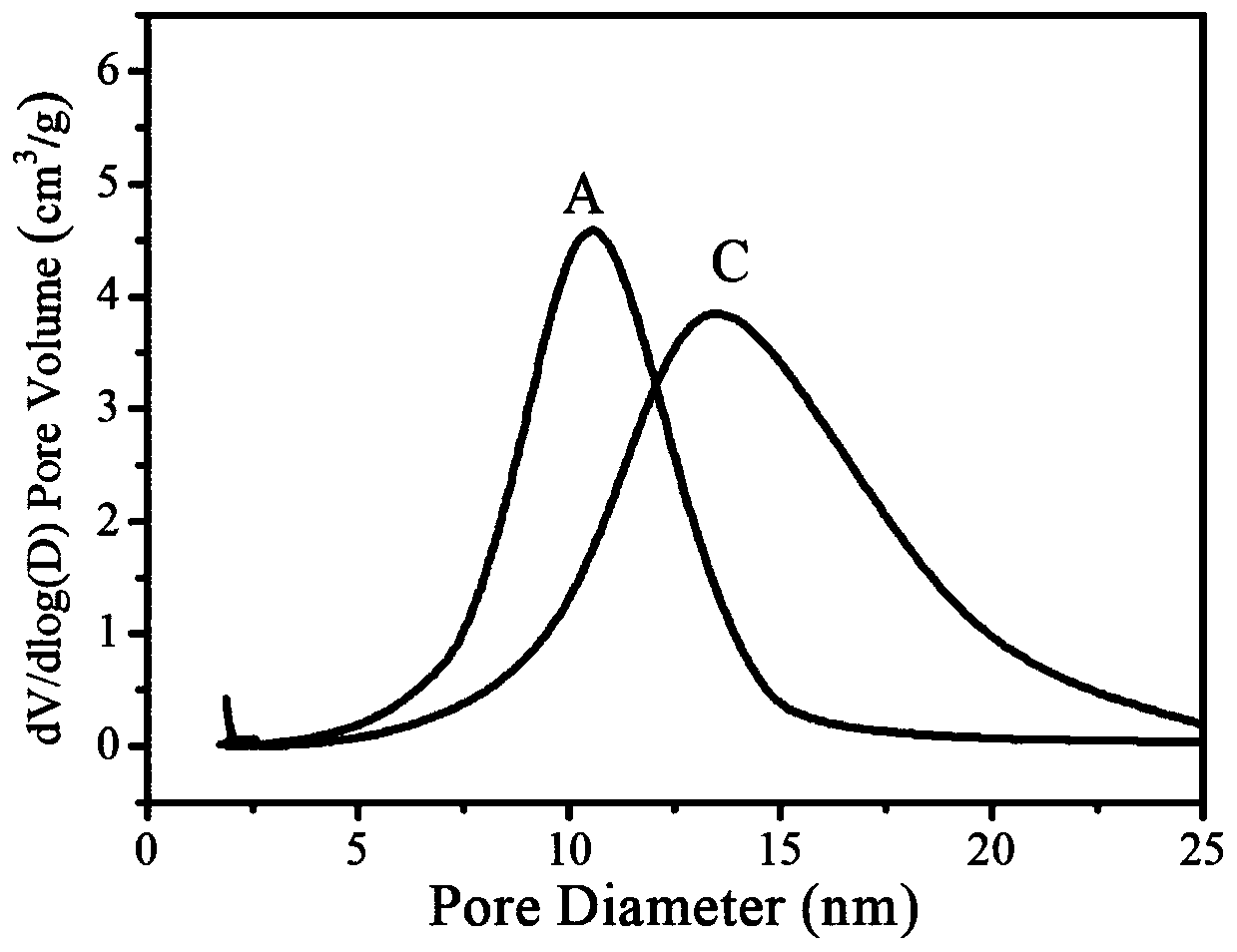

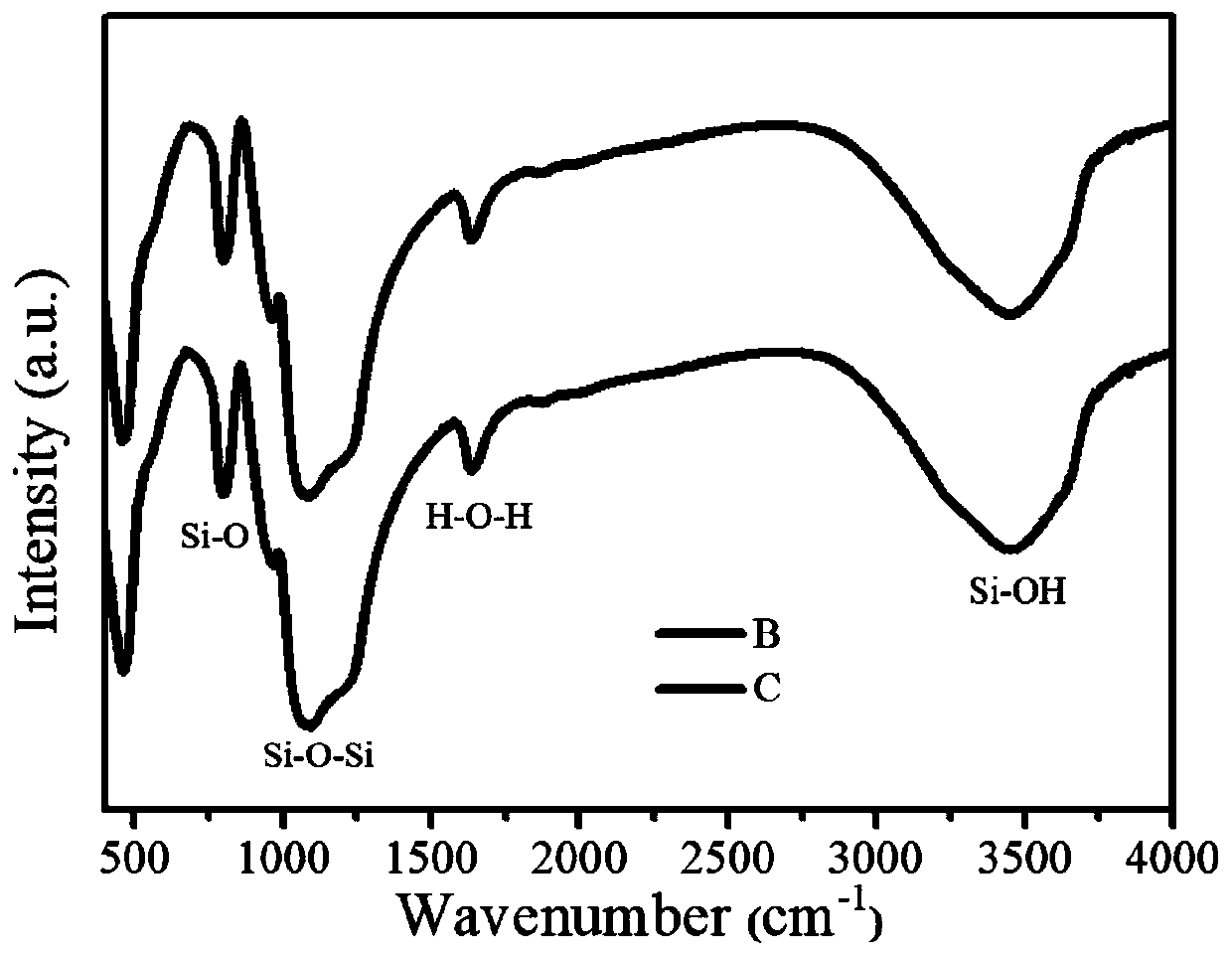

Embodiment 1

[0029] (1) First weigh 3g of TX-100 surfactant, then add it into 50mL of sulfuric acid solution (3mol / L) and stir vigorously at 50°C for 24h (stirring speed is 600r / min) to fully dissolve it. After the stirring was completed, 10 mL of porogen ethanol was added and the stirring was continued for 12 h to obtain a mixed solution A. Then add olivine with a certain particle size (0.5mm) to the above mixed solution A, and continue to stir vigorously at 50°C for 24h (stirring rate is 700r / min), after the stirring is completed, the obtained mesoporous silicon precursor is decanted It is separated from unreacted substances, and at the same time, the impurity components in olivine are also dissolved by acid, and aged at 60°C for 12h. Among them, the TX-100 surfactant promotes the silicon in olivine to form an ordered combination by virtue of its special amphiphilicity, and the porogen effectively fills the combination, and then continues to separate the aged silicon precursor Wash with...

Embodiment 2

[0032] (1) First weigh 4g of TX-10 surfactant, then add it into 55mL of sulfuric acid solution (4mol / L) and stir vigorously at 40°C for 24h (stirring speed is 500r / min) to fully dissolve it. After the stirring was completed, 8 mL of porogen glycerol was added and the stirring was continued for 16 h to obtain a mixed solution A. Next, olivine with a certain particle size (0.8mm) was added to the above mixed solution A, and continued to stir vigorously at 40°C for 16h (stirring rate was 600r / min), and after the stirring was completed, the obtained mesoporous silicon precursor was decanted It is separated from unreacted substances, and at the same time, the impurity components in olivine are also dissolved by acid, and aged at 60 ° C for 8 hours. Among them, the TX-100 surfactant promotes the silicon in olivine to form an ordered combination by virtue of its special amphiphilicity, and the porogen effectively fills the combination, and then continues to separate the aged silicon ...

Embodiment 3

[0035] (1) First weigh 3.5g of SE-10 surfactant, then add it into 40mL of hydrochloric acid solution (5mol / L) and stir vigorously at 35°C for 24h (stirring speed is 400r / min) to fully dissolve it. After the stirring was completed, 5 mL of porogen heptane was added and the stirring was continued for 10 h to obtain a mixed solution A. Next, serpentine with a certain particle size (1.0mm) was added to the above mixed solution A, and continued to stir vigorously at 35°C for 16h (stirring rate was 500r / min). After the stirring was completed, the obtained mesoporous silicon precursor was decanted The body is separated from the unreacted substance, and at the same time, the impurity components in the serpentine are also dissolved by acid, and aged at 60 ° C for 10 h. Among them, the TX-100 surfactant promotes the silicon in the serpentine to form an ordered combination by virtue of its special amphiphilicity, and the porogen effectively fills the combination, and then continues to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com