Wet electrostatic dust collector for fresh air system

A wet electrostatic and fresh air system technology, applied in the field of air purification, can solve the problems of reduced dust removal efficiency, secondary dust, and increased user operating costs, and achieve the effect of convenient replacement and maintenance and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

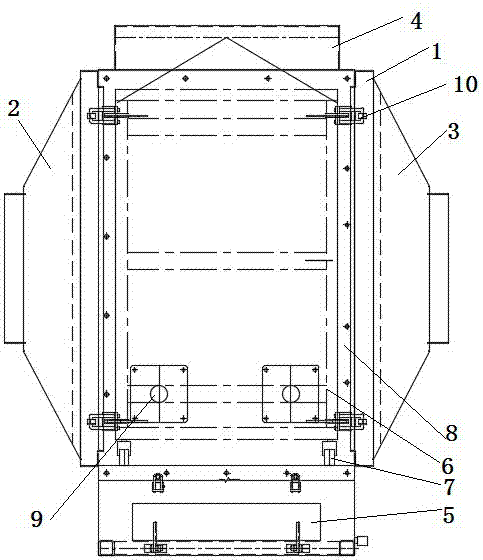

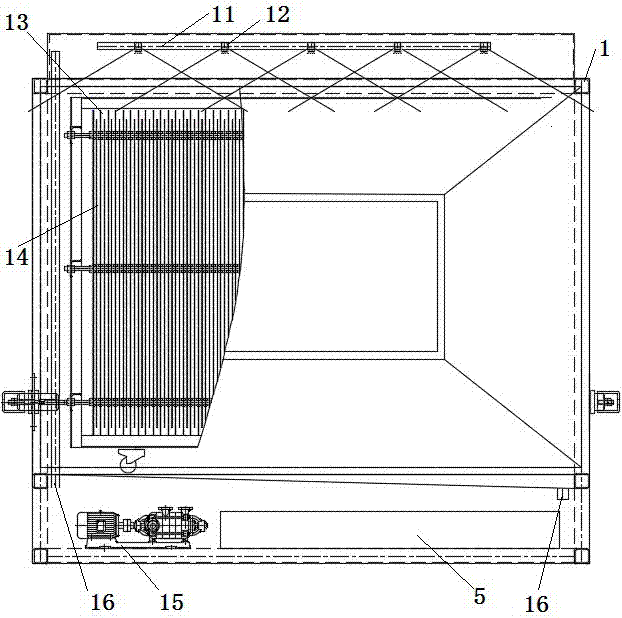

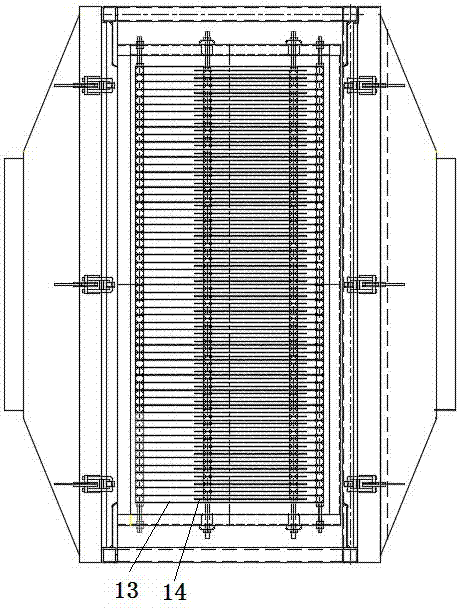

[0020] Example: as attached figure 1 , with figure 2 And attached image 3 As shown, a wet electrostatic precipitator for a fresh air system includes a housing 1, an anode system 13 and a cathode system 14. The opposite sides of the housing are air inlets and air outlets. The upper end of the housing is provided with a spray system 4. The body is provided with an inlet speaker 2 at the air inlet, and the housing is provided with an outlet speaker 3 at the air outlet. The inside of the housing is hollow, one side of the housing is open, and a maintenance door 8 is provided on the opening side of the housing. The plate frame 6 is fixedly connected to the anode system and the cathode system, the bottom of the plate frame is provided with a roller 7, and the lower end of the shell is provided with a water collection tank 5, and the lower part of the shell is connected to the water collection tank through a hose 16, and spray The system includes a nozzle 11 and a nozzle 12, nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com