Coke oven waste gas utilization device and application method thereof

A coke oven gas and coke oven technology, applied in the coking field, can solve problems such as large water demand, and achieve the effects of low renovation cost, low construction cost, and sufficient gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Coke oven waste gas utilization device

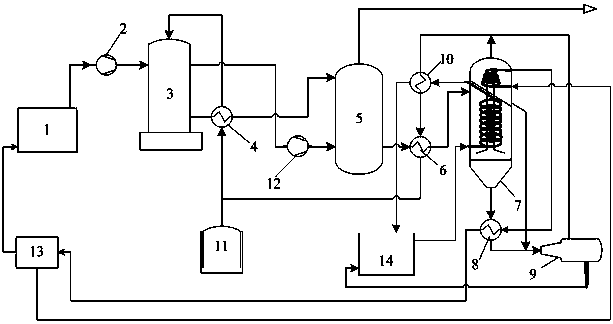

[0029] figure 1 A schematic flow chart of the utilization of coke oven waste gas in the present invention is shown.

[0030] A coke oven waste gas utilization device, comprising a coke oven 1, an air separator 13, a coke oven gas tank 11, a multi-stage gas-liquid separator 7, an expansion flash evaporator 9, a reformer 3, and a chemical synthesizer 5; The furnace 1 is connected to the reformer 3 through the compressor 2, the syngas outlet at the upper end of the reformer 3 is connected to the chemical synthesizer 5 through the booster 12, and the exhaust gas outlet at the lower end of the reformer 3 is connected with the chemical synthesis gas through the mixed gas preheater 4 The product synthesizer 5 is connected; the exhaust gas outlet at the lower end of the chemical synthesizer 5 is connected with a multi-stage gas-liquid separator 7, and the multi-stage gas-liquid separator 7 is a cyclone spiral pipeline heat ex...

Embodiment 2

[0035] Embodiment 2: Coke oven waste gas utilization method

[0036] The specific steps are:

[0037] (1) Heating of exhaust gas and separation of exhaust gas:

[0038] Exhaust gas at 400°C produced by coke oven 1 is pressurized at 10,000 kmol / h by compressor 2 to 3.5MPa and then enters reformer 3. The temperature of the exiting gas drops to 380°C. After heat exchange by mixed gas preheater 4, it enters the chemical Synthesizer 5, inlet 300°C, 3.44MPa, outlet 260°C, 3.42 MPa, then cooled to 200°C by waste gas cooler 6, enters multi-stage gas-liquid separator 7, heat exchange through cyclone spiral tube, bottom outlet temperature 130°C, Pressure 3.38MPa, superheated water 3795.19 kmol / h (including CO 2 6.56 v%) with CO 2 Saturated water vapor (CO 2 Content 31.44 v%) rises from the middle standpipe and enters the top through the conical liquid nitrogen coil, and the outlet temperature at the top drops to 40°C (containing 99.9% CO 2 ), 4253.03 kmol / h H 2 O leads out from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com