Natural-fiber artificial leather and manufacturing method thereof

A technology for simulating leather and natural fibers, applied in textiles and papermaking, etc., can solve the problems of increasing the content of organic chemical components in artificial leather, reducing product environmental protection, and high production and processing costs, shortening dyeing time, reducing water energy consumption, and reducing Effects of wastewater discharge and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

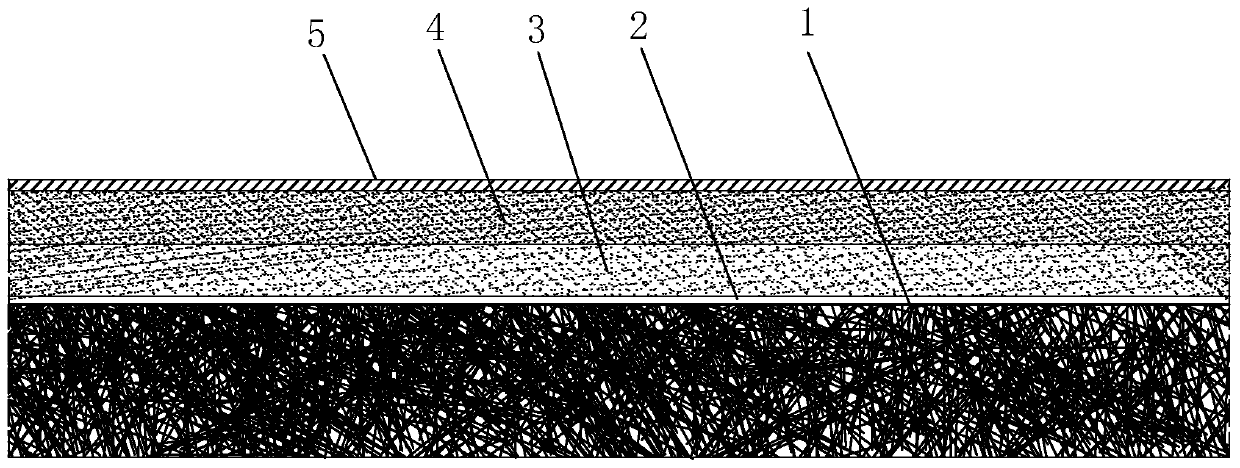

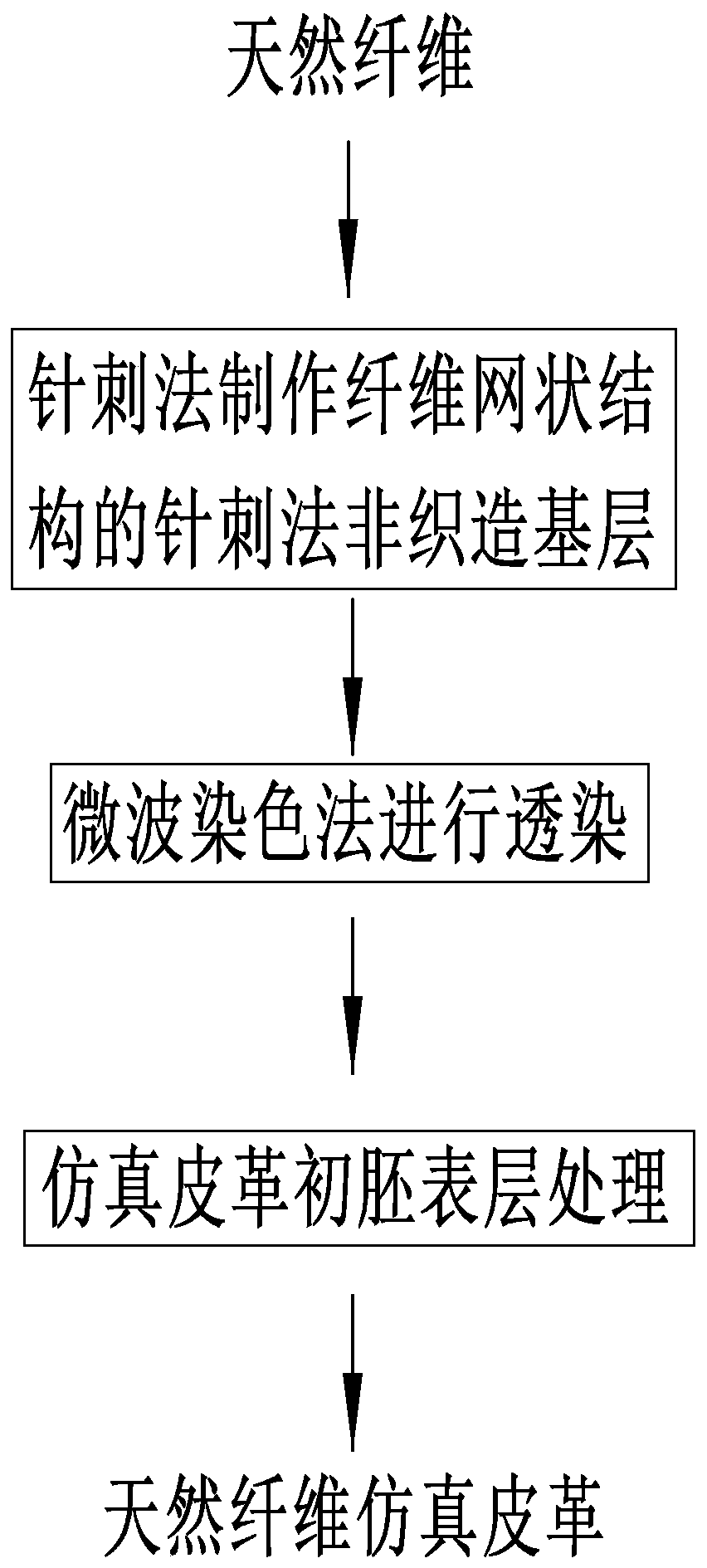

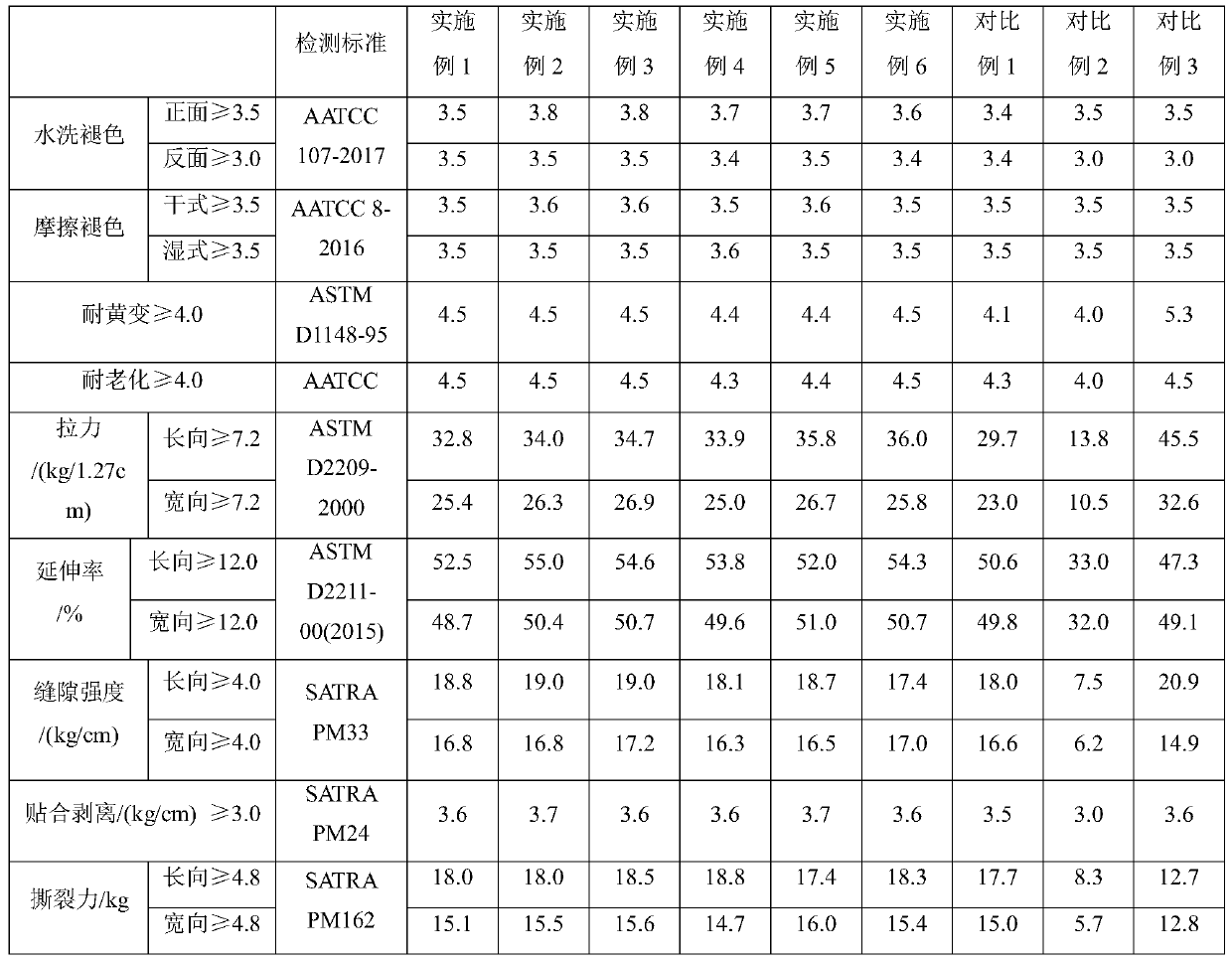

[0039] A natural fiber imitation leather, such as figure 1 As shown, it includes needle-punched nonwoven base layer 1, cover layer 2, first resin layer 3, second resin layer 4 and oil wax layer 5 from bottom to top. Needle-punched non-woven base layer 1 is made of natural fibers through needles. It is formed by interweaving by needle punching method, and the inside of the needle punching method nonwoven base layer 1 is a fiber network structure. The natural fiber in the present invention can select plant fiber for use, as pineapple leaf, banana leaf, tencel fiber etc., also can select animal hair fiber for use, such as wool fiber, cow hair fiber etc., fiber length needs to reach not less than 2cm, make acupuncture machine The processed fiber network structure is more compact and strong. The interior of the needle-punched non-woven base layer 1 is dyed with chemical dyes through the microwave dyeing method, so that the interior has the same color as the desired leather product...

Embodiment 2

[0052] The natural fiber artificial leather of embodiment 2 is the same as the layer structure and composition thereof of embodiment 1, the difference is that the manufacturing process is different, specifically:

[0053] (1) Production of needle-punched nonwoven substrate

[0054] Manufactured to form a thickness of 1.5mm, 400g / m 2 The needle-punched nonwoven base layer, all the other are identical with the step (1) of embodiment 1;

[0055] (2) Internal dyeing treatment of needle-punched nonwoven substrate

[0056] The transmission speed of the needle-punched non-woven base layer is 3m / min, the microwave power is 11kw, the drying temperature of microwave dyeing is 60°C, and the overall duration is 15min; the dyeing agent for microwave penetration dyeing includes the following components by weight: dyestuff : leather penetrating agent: water is 1: 0.05: 10, and water temperature is controlled at 37 ℃; Dyestuff then is according to the needs of actual production and processi...

Embodiment 3

[0060] The layer structure and composition thereof of the natural fiber imitation leather of embodiment 3 are identical with embodiment 1, and difference is that manufacturing process is different, specifically:

[0061] (1) Production of needle-punched nonwoven substrate

[0062] Manufactured to form a thickness of 1.8mm, 600g / m 3 The needle-punched nonwoven base layer, all the other are identical with the step (1) of embodiment 1;

[0063] (2) Internal dyeing treatment of needle-punched nonwoven substrate

[0064] The transmission speed of the needle-punched non-woven substrate is 3m / min, the microwave power is 15kw, the drying temperature of microwave dyeing is 70°C, and the overall dyeing time is 14min; the dyeing agent for microwave penetration dyeing includes the following components by weight: Dye: leather penetrating agent: water is 1: 0.05: 10, and water temperature is controlled at 40 ℃; Dyestuff then is according to the needs of actual production and processing, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com