Dope-Dyed Core-Sheath Type Composite Fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

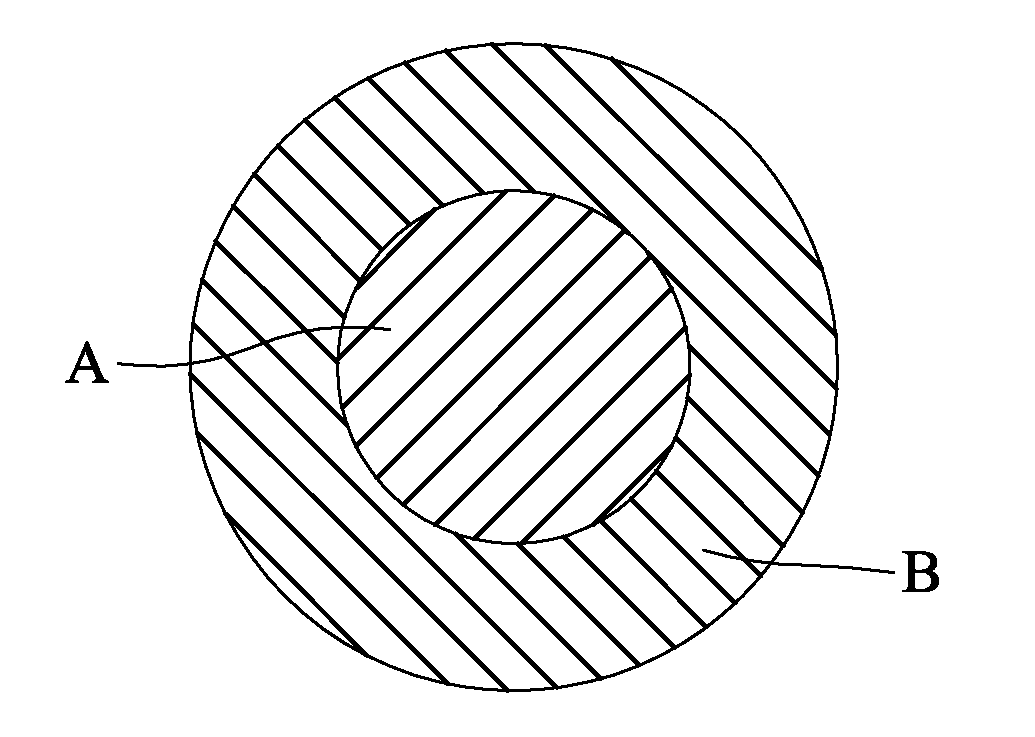

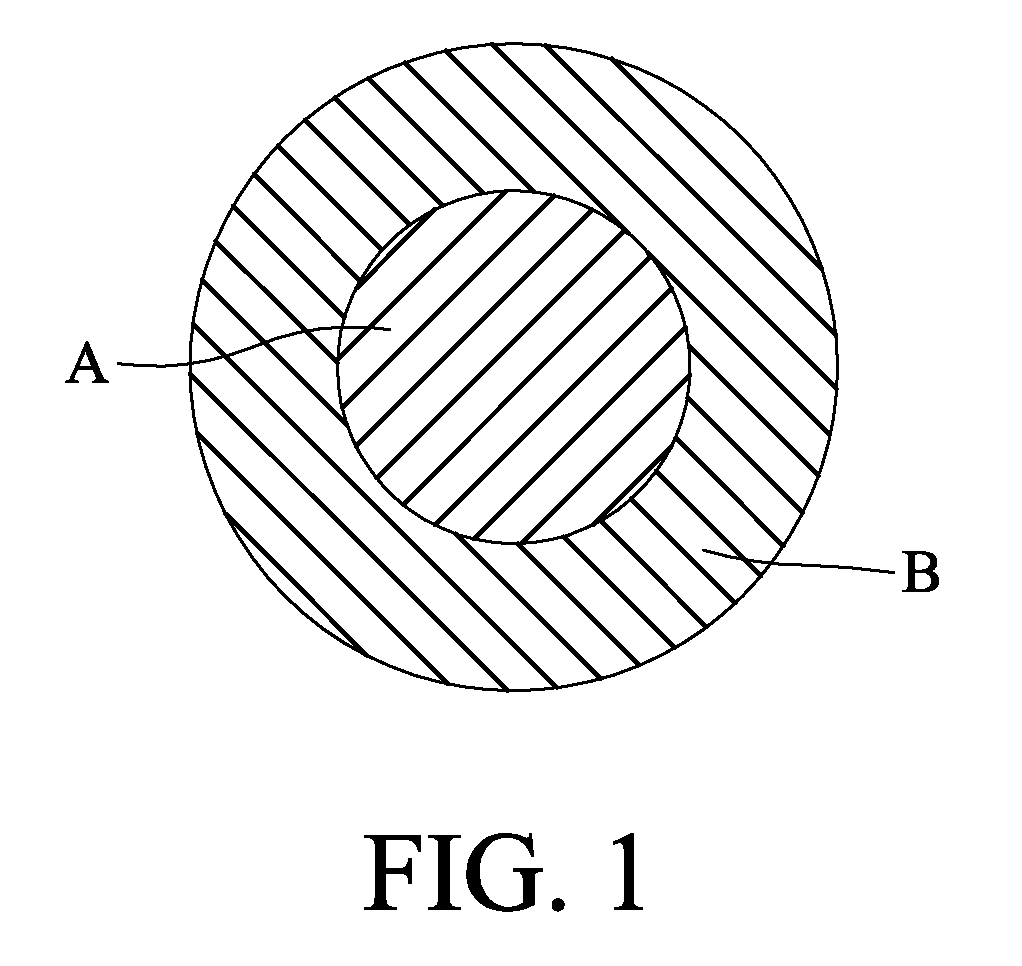

[0018]A dope-dyed core-sheath type composite fiber according to a first embodiment of the present invention is a Spin Draw Yarn (SDY) of polyester conjugate multi-filament yarn with 1.04 Denier-per-filament. Composite of the core layer A is semi-dull polyester polymer which contains 0.3 wt % of titanium dioxide, and the core layer A is dope dyed with Solvent Blue 122 through a masterbatch meter so as to form 2.0wt % content in the core part. Composite of the sheath layer B is semi-dull polyester polymer which contains 0.3 wt % of titanium dioxide, the sheath layer B is not dope dyed, a cross-sectional area ratio of the sheath layer B and the core layer A is 50 / 50, i.e., X(B)=50%, spinning speed is 4500 m / min, and the extension ratio is 3.2 times.

[0019]Comparative Example 1 is a Spin Draw Yarn (SDY) mono component polyester multi-filament yarn with 1.04 Denier-per-filament. The composite is semi-dull polyester polymer which contains 0.3 wt %t of titanium dioxide and is dope dyed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com