High-fastness black vat dye and preparation method thereof

A dye fastness technology, applied in the field of high-fastness black vat dyes and its preparation, can solve the problems of sun resistance, low washing fastness, low pad dyeing rate, suspension dispersion stability and poor diffusibility, etc. problems, achieve excellent washing fastness, simple preparation method and excellent color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

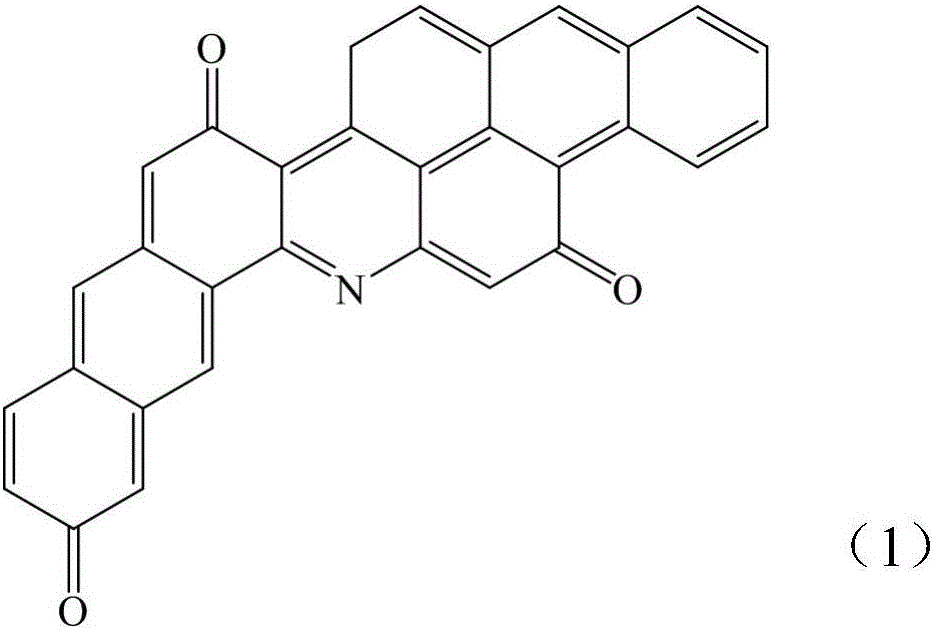

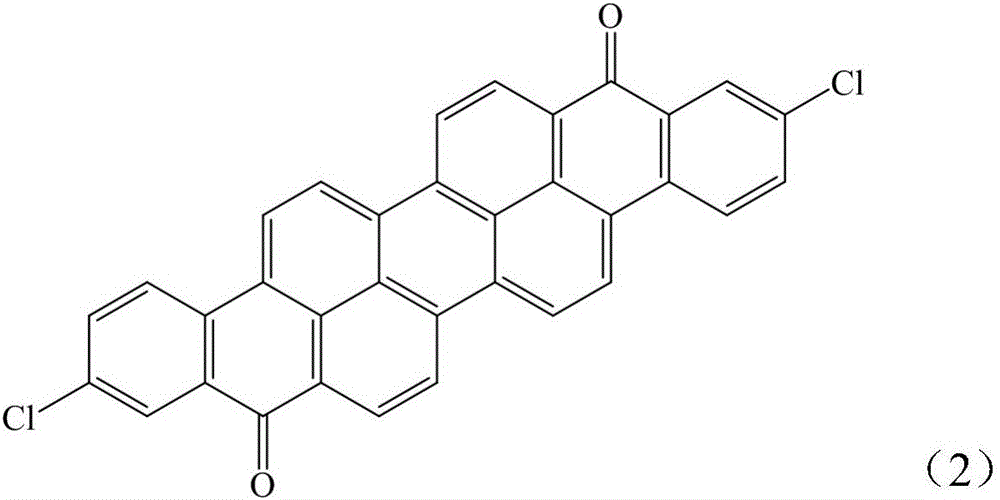

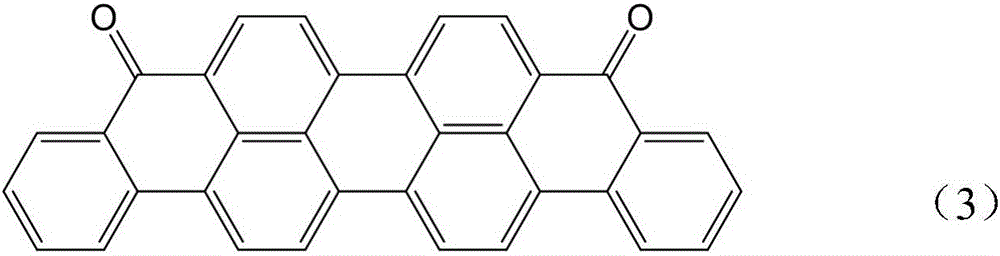

Image

Examples

Embodiment

[0022] The composition and mass percentage content of the black vat dye of high fastness in embodiment 1-5 are as follows table 1:

[0023] Table 1

[0024]

[0025]

[0026] The preparation method of the black vat dye with high fastness, the steps are as follows: Weigh the filter cakes of the dye monomers A, B, C and D in proportion, add them to the dispersing kettle, add a dispersant to beating to obtain a slurry, and mix the slurry Transfer to a liquid fine grinder for crushing, and then transfer to a sand mill for grinding for 65-70 hours. The fineness of the slurry after grinding is 0.5-2 μm. Sonicate for 5 minutes while stirring, and transfer to a microwave drying room for drying within 3 minutes. At the same time, spray dustproof agent, and finally pack the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com