High-emulation bamboo joint longitude and latitude heterochromatic textile and preparation method thereof

A textile fabric, warp and weft technology, applied in the field of preparation of the fabric, can solve the problems of poor color fastness, dull luster, poor wearing comfort, etc., achieve excellent elasticity, unique style and comfort, and improve the effect of wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

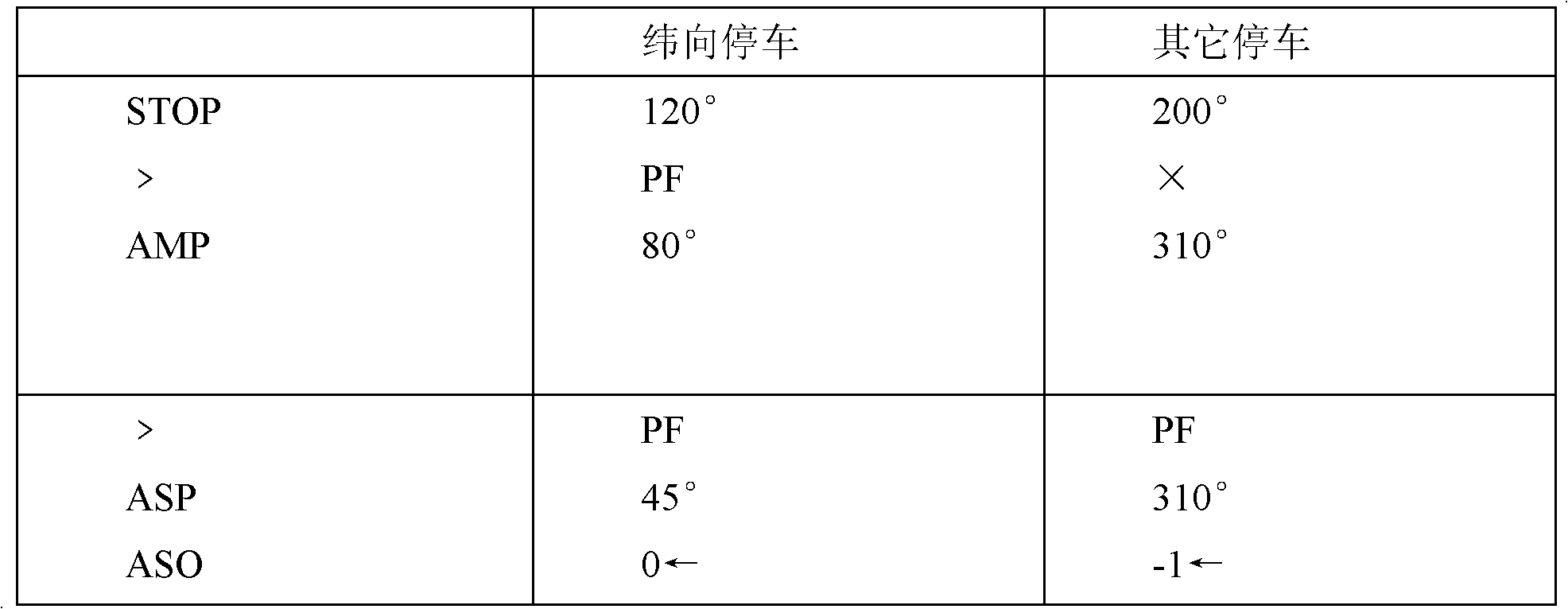

Image

Examples

Embodiment

[0024] Embodiment: the preparation method of highly simulated slub warp and weft heterochromatic textile fabrics is characterized in that it comprises the following steps:

[0025] ①Warp yarn preparation: Warp yarns include A warp and B warp. The aforementioned A warp is formed by twisting and spinning 40 denier spandex through a core-spun yarn with a thickness of 32 inches. The aforementioned B warp has a thickness of 21 inches. The core-spun yarn of 40 deniers is wrapped into the spandex twist spinning of 40 deniers. The aforementioned core-spun yarn is composed of 65% by weight of cationic polyester fiber and 35% by weight of viscose fiber; and then warping in batches , sizing, drafting, sizing with a double sizing machine, and adding food coloring into the sizing tank of the second warp, so that the second warp is colored, so that the warp A and the warp B are easy to distinguish during the weaving process;

[0026] ②Weft yarn preparation: the weft yarn includes A weft and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com