Production process of chemical fabric with good air permeability

A production process, the technology of chemical fiber cloth, applied in the field of chemical fiber cloth production technology, can solve the problems of poor air permeability of chemical fiber fabrics, insufficient wearing comfort, affecting the quality of fabrics, etc., achieve brilliant colors, improve elasticity and wear resistance Shape retention and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

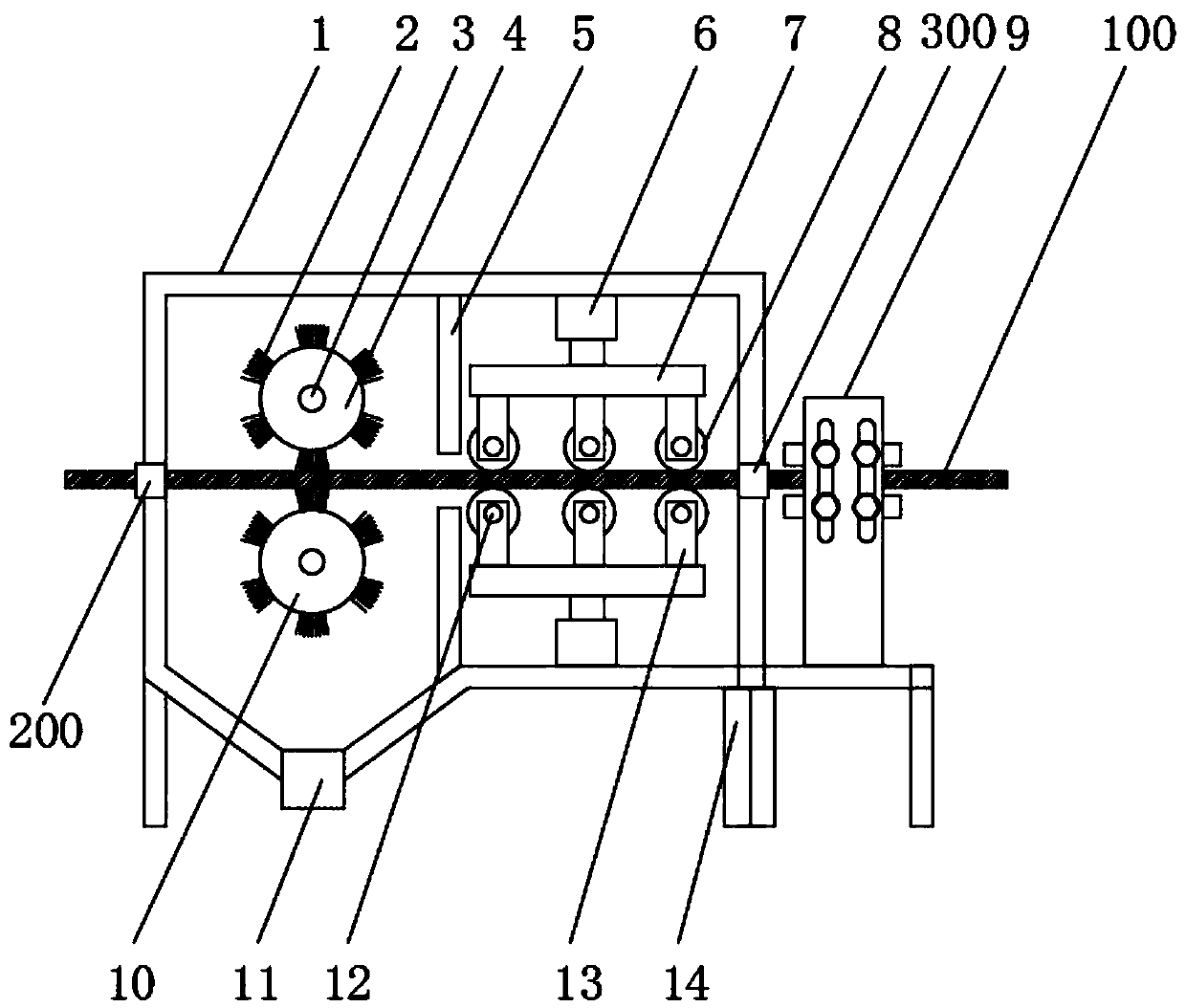

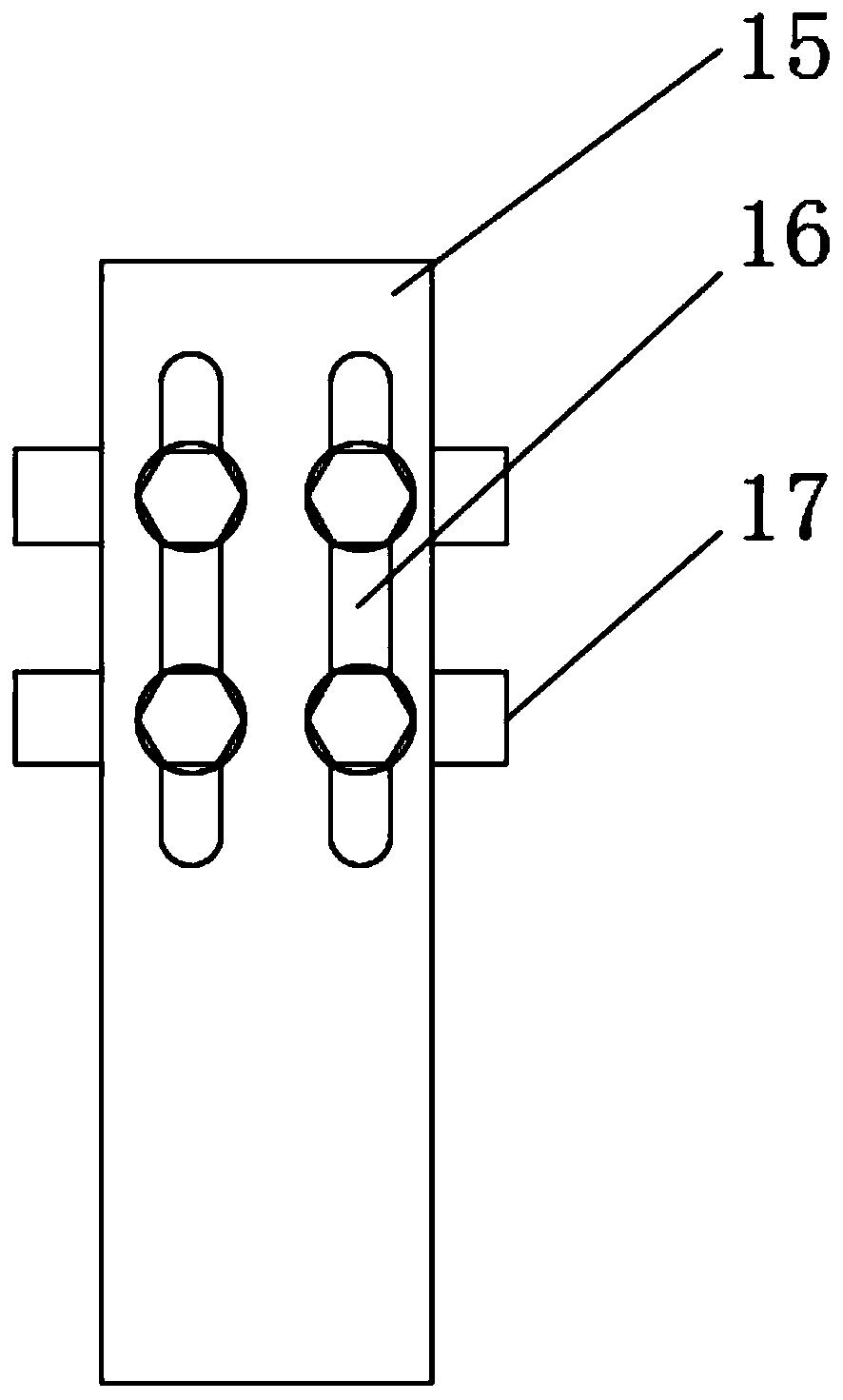

[0038] see Figure 1-6 As shown, the present embodiment is a production process of a kind of chemical fiber cloth with good air permeability, comprising the following steps:

[0039] Step 1: Take 60 parts of viscose fiber and 40 parts of polyester fiber by weight;

[0040] Step 2: Yarn selection and weaving: drawing and co-extruding viscose fiber to form viscose fiber spinning, drawing and co-extruding polyester fiber to form polyester fiber spinning, selecting viscose fiber spinning as warp, and selecting polyester fiber spinning as Weft, the warp and weft are woven into a blended fabric through a weaving machine;

[0041] Step 3: Bleaching and impregnation: Put the blended fabric into the impregnation device for impregnation, add liquid alkali and whitening agent to the impregnation device, add additives, and impregnate for 3-4 hours;

[0042] Step 4: Prepare the dye solution:

[0043] S1. Weigh the following raw materials by weight: 10 parts of polyethylene resin, 6 part...

Embodiment 2

[0053] see Figure 1-6 As shown, the present embodiment is a production process of a kind of chemical fiber cloth with good air permeability, comprising the following steps:

[0054] Step 1: Weigh 70 parts of viscose fiber and 30 parts of polyester fiber by weight;

[0055] Step 2: Yarn selection and weaving: drawing and co-extruding viscose fiber to form viscose fiber spinning, drawing and co-extruding polyester fiber to form polyester fiber spinning, selecting viscose fiber spinning as warp, and selecting polyester fiber spinning as Weft, the warp and weft are woven into a blended fabric through a weaving machine;

[0056] Step 3: Bleaching and impregnation: Put the blended fabric into the impregnation device for impregnation, add liquid alkali and whitening agent to the impregnation device, add additives, and impregnate for 3-4 hours;

[0057] Step 4: Prepare the dye solution:

[0058] S1. Weigh the following raw materials by weight: 12 parts of polyethylene resin, 7 par...

Embodiment 3

[0068] see Figure 1-6 As shown, the present embodiment is a production process of a kind of chemical fiber cloth with good air permeability, comprising the following steps:

[0069] Step 1: Take 80 parts of viscose fiber and 20 parts of polyester fiber by weight;

[0070] Step 2: Yarn selection and weaving: drawing and co-extruding viscose fiber to form viscose fiber spinning, drawing and co-extruding polyester fiber to form polyester fiber spinning, selecting viscose fiber spinning as warp, and selecting polyester fiber spinning as Weft, the warp and weft are woven into a blended fabric through a weaving machine;

[0071] Step 3: Bleaching and impregnation: Put the blended fabric into the impregnation device for impregnation, add liquid alkali and whitening agent to the impregnation device, add additives, and impregnate for 3-4 hours;

[0072] Step 4: Prepare the dye solution:

[0073] S1. Weigh the following raw materials by weight: 15 parts of polyethylene resin, 8 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com