Composite activity black dye

A black dye, reactive technology, applied in the field of dyes, can solve the problems of poor reproducibility, cloudy color fastness, poor washability, etc., and achieve good selectivity, excellent color fastness, and easy washability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

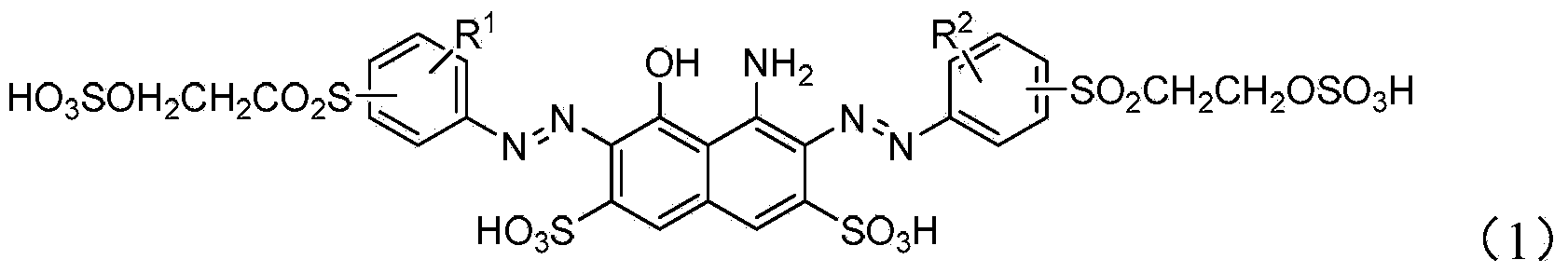

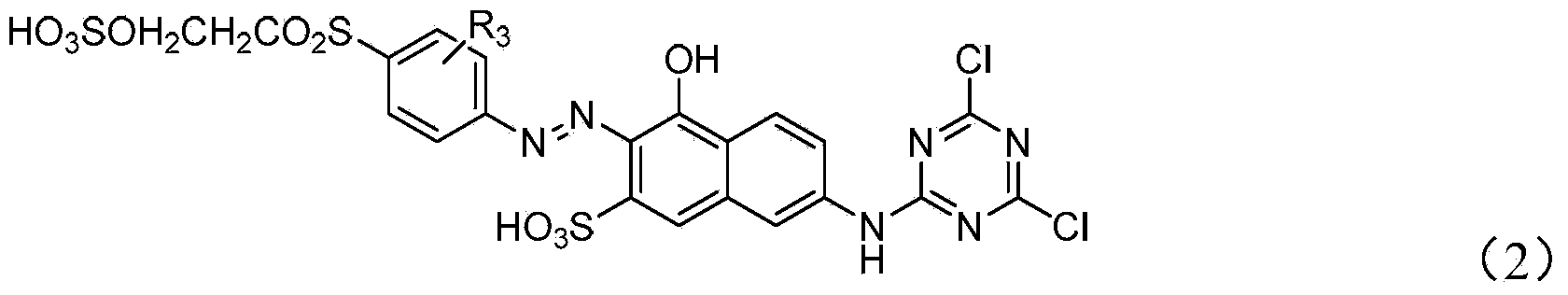

Method used

Image

Examples

Embodiment 1~15

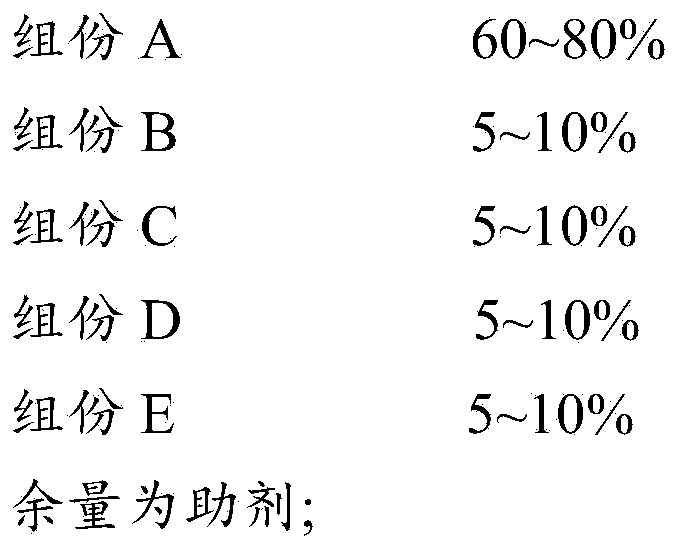

[0048] According to the data in Table 1, mix the dye component A, dye component B, dye component C, dye component D, dye component E, and auxiliaries using blending equipment, or directly mix the liquid slurry uniform.

[0049] Table 1

[0050]

[0051]

[0052] The reactive dyes prepared in the above examples were dyed with standard reactive dyes to obtain their corresponding performance data, as shown in Table 2. The relevant standards used are:

[0053] GB / T2374-2007 General Conditions for Dyeing Determination;

[0054] GB / T2387-2006 Determination of shade and intensity of reactive dyes;

[0055] GB / T3920-1997 Textile color fastness test Color fastness to rubbing (eqv ISO105-X12: 1993);

[0056] GB / T3921.4-1997 Textile color fastness test Color fastness to washing (eqv ISO105-C04: 1989);

[0057] GB / T3922-1995 Test method for color fastness to perspiration of textiles (eqv ISO105-E04: 1994);

[0058] Table 2

[0059]

[0060] Through the detection data analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com