Method for preparing green regenerated cellulose fiber by taking vinasse as raw material

A technology of regenerated cellulose and cellulose, applied in the direction of single-component cellulose rayon, spinning solution preparation, fiber raw material treatment, etc., can solve the problems of insufficient development and research on the high-value utilization of distiller's grains, etc. Achieve excellent antibacterial properties, excellent mechanical properties, and good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

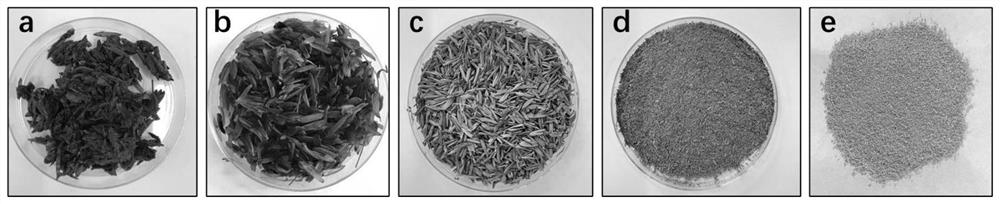

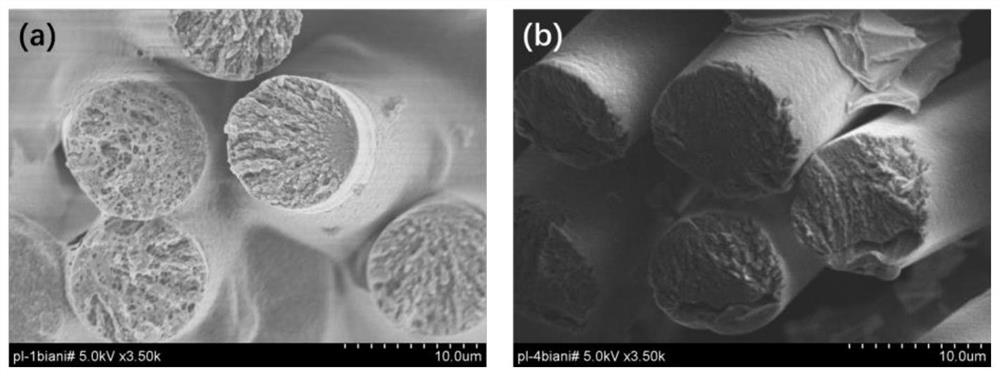

[0045] The present embodiment provides a method for preparing green regenerated cellulose fibers with distiller's grains as a raw material, and the steps are:

[0046] (1) Preparation of distiller's grains lignocellulose, placing the fragrant white distiller's grains in a 0.5% sodium hydroxide solution for immersion, the immersion bath ratio is 12:1, and the mechanical stirring is carried out at the same time, and the immersion temperature is 50°C, and the immersion time is 1.5h, the stirring speed is 700RPM. After the immersion is completed, 300-mesh stainless steel gauze is used for filtration, repeated water washing, re-filtration, and then drying at 60° C. for 4 hours, and then sieving to obtain distiller’s grains lignocellulose.

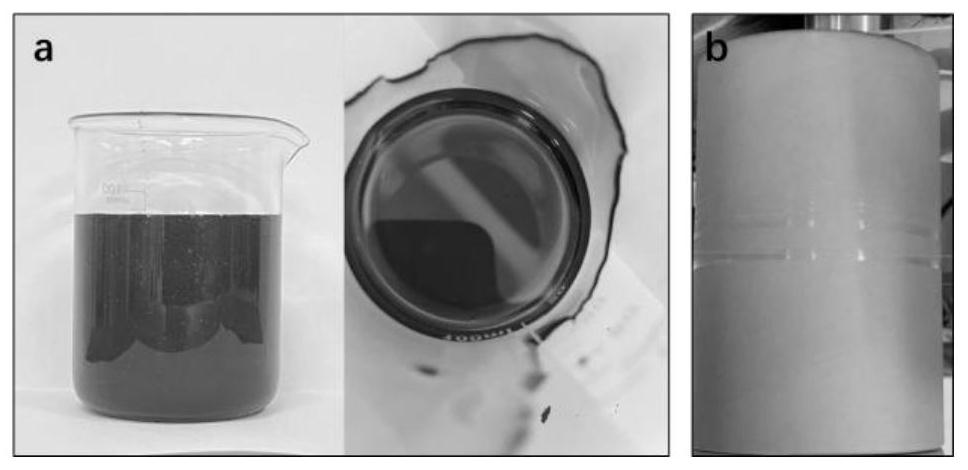

[0047] (2) Preparation of distiller's grains cellulose, the above-obtained distiller's grains lignocellulose was added to a 13% sodium hydroxide solution according to a liquor ratio of 9:1 for alkalization, the alkalization temperature was 80°C,...

Embodiment 2

[0052] The present embodiment provides a method for preparing green regenerated cellulose fibers with distiller's grains as a raw material, and the steps are:

[0053] (1) Preparation of lignocellulose from distiller's grains, dipping beer's distiller's grains in a 0.1% sodium hydroxide solution by mass, the immersion bath ratio is 16:1, and at the same time, mechanical stirring is performed, the immersion temperature is 35°C, and the immersion time is 0.5h , the stirring speed is 200RPM. After the immersion is completed, 300-mesh stainless steel gauze is used for filtration, repeated water washing, re-filtration, and then drying at 50° C. for 3 hours, and then sieving to obtain distiller’s grains lignocellulose.

[0054] (2) Preparation of distiller's grains cellulose, the above-obtained distiller's grains lignocellulose was added to 8% sodium hydroxide solution according to the liquor ratio of 5:1 for alkalization, the alkalization temperature was 60°C, and the alkalization ...

Embodiment 3

[0059] (1) The preparation of distiller's grains lignocellulose, the mixed distiller's grains with beer's grains / white wine's grains of 1 / 2 is placed in a 1% sodium hydroxide solution for dipping, and the dipping bath ratio is 18:1, while mechanical stirring, The immersion temperature was 60°C, the immersion time was 2h, and the stirring speed was 800RPM. After the immersion is completed, filter with 300-mesh stainless steel gauze, repeatedly wash with water, filter again, and then dry at 85° C. for 8 hours and then sieve to obtain distiller’s grains lignocellulose.

[0060] (2) Preparation of distiller's grains cellulose, the above-obtained distiller's grains lignocellulose was added to 14% sodium hydroxide solution according to the liquor ratio of 10:1 for alkalization, the alkalization temperature was 90°C, and the alkalization time was 4h, The alkalized product is filtered with a 300-mesh stainless steel gauze, and the filtered product is transferred to a sodium sulfite / so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com