Bamboo hemp cotton blended compact spinning yarn and producing method thereof

A production method, bamboo hemp cotton technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems affecting the production efficiency of looms, reducing the competitiveness of ramie industry products, and affecting the wearing performance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

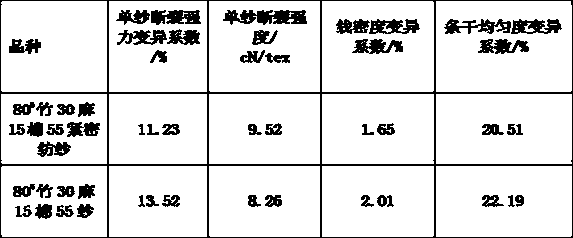

[0018] Spinning 80 S Bamboo 30 Hemp 15 Cotton 55 Yarn

[0019] Use ramie combed slivers to cut, the cutting length is 40 mm, do not open, add 3-4% oil for later use.

[0020] Based on 100% of the weight, bamboo fiber and ramie fiber are selected in a ratio of 66:34, and they are evenly stacked in the plucking machine. The weight of the sesame sticks is controlled at 16g / 5m. Carding licker-in gap is 20 mm, cylinder to licker-in speed ratio is 1:3, licker-in speed is 1000 rpm.

[0021] Cotton fibers are evenly stacked in the plucking machine, and after grasping, mixing, opening, impurity removal, and carding, cotton slivers are made, and the weight of the cotton slivers is controlled at 21 grams / 5 meters. Carding licker-in gap is 22 mm, cylinder to licker-in speed ratio is 1:2, licker-in speed is 1100 rpm.

[0022] The raw cotton slivers are combined and combed to further remove short fibers and impurities. The number of slivers fed into the slivers is 22, the speed of the l...

Embodiment 2

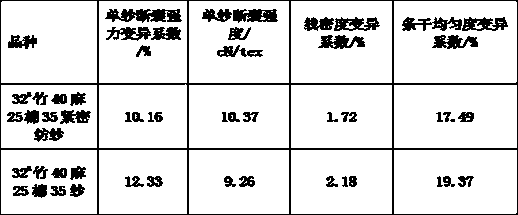

[0030] Spinning 32 S Bamboo 40 Hemp 25 Cotton 35 Yarn

[0031] Select the degummed ramie fine dry hemp, the cut length is 55 mm, the number of opening channels is 4, and 4-6% emulsion is added for later use.

[0032] Based on 100% of the weight, bamboo fiber and ramie fiber are selected in a ratio of 61:39, and they are evenly stacked in the plucking machine. The weight of the sesame sticks is controlled at 20 grams / 5 meters. Carding licker-in gap is 20 mm, cylinder to licker-in speed ratio is 1:3, licker-in speed is 950 rpm.

[0033] The cotton fibers are evenly stacked in the plucking machine, and after grasping, mixing, opening, impurity removal, and carding, cotton slivers are made, and the weight of the cotton slivers is controlled at 20 grams / 5 meters. Carding licker-in gap is 22 mm, cylinder to licker-in speed ratio is 1:2, licker-in speed is 1000 rpm.

[0034] The raw cotton slivers are combined and combed to further remove short fibers and impurities. The number o...

Embodiment 3

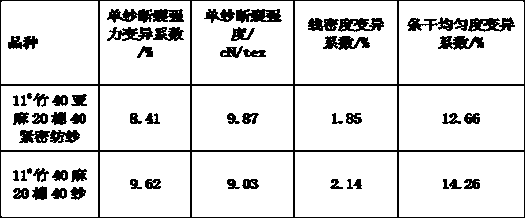

[0042] Spinning 11 S Yarn bamboo 40 hemp 20 cotton 40

[0043] Select semi-degummed flax fine dry flax, cut length is 65 mm, and the number of opening is 3, add 2-4% emulsion for later use.

[0044]Based on 100% by weight, bamboo fiber and flax fiber are selected in a ratio of 65:35, and they are evenly stacked in the plucking machine, and after grasping, mixing, opening, impurity removal, and carding, raw bamboo and flax fibers are made. The weight of raw bamboo flax strips is controlled at 20g / 5m. Carding licker-in gap is 21 mm, cylinder to licker-in speed ratio is 1:3, licker-in speed is 900 rpm.

[0045] Cotton fibers are evenly stacked in the plucking machine, and after grasping, mixing, opening, impurity removal, and carding, cotton slivers are made, and the weight of the cotton slivers is controlled at 22.2 grams / 5 meters. Carding licker-in gap is 22 mm, cylinder to licker-in speed ratio is 1:2, licker-in speed is 1000 rpm.

[0046] On the drawing frame, 3 raw cotto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com