Light dustproof and ventilating bulk cargo warehouse

A light-weight, warehouse-based technology, applied in large-capacity bulk material storage, shockproof, building components, etc., can solve the problems of unorganized dust emission, long construction period, and high ground foundation requirements, and achieve low cost and low price. Low, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

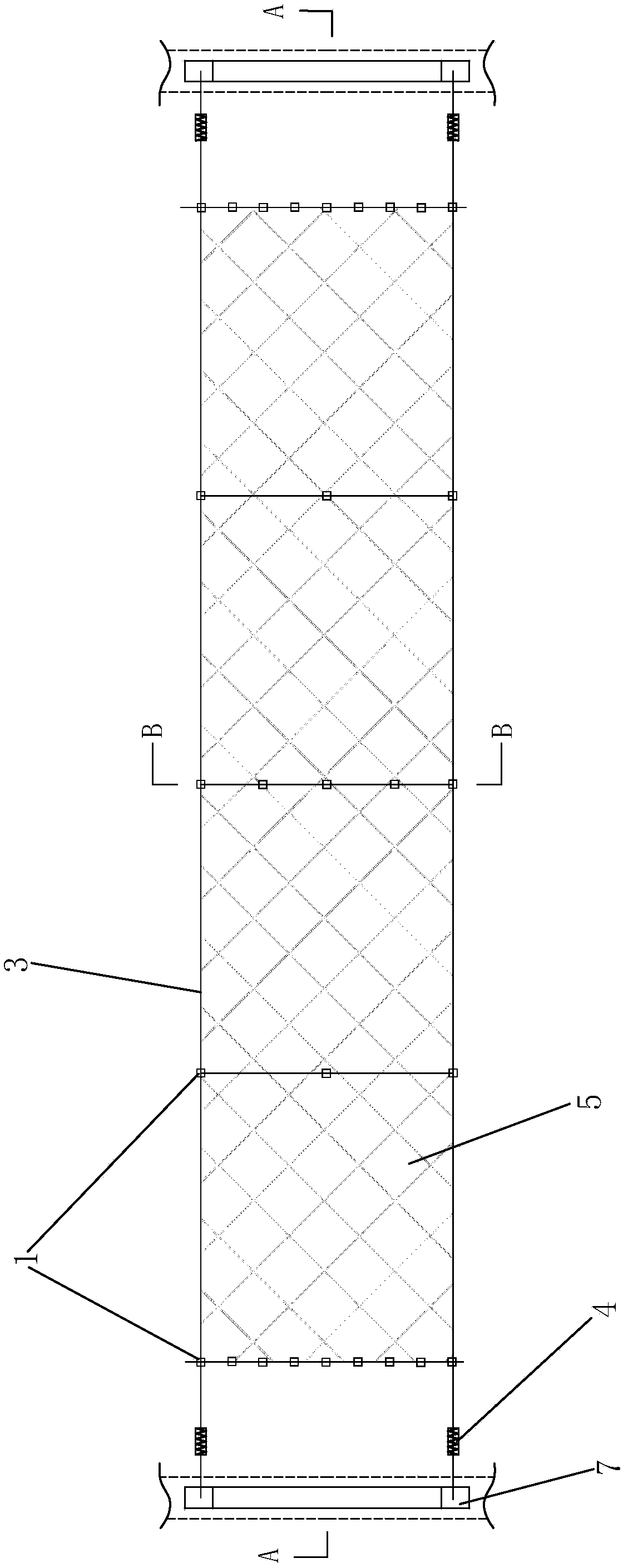

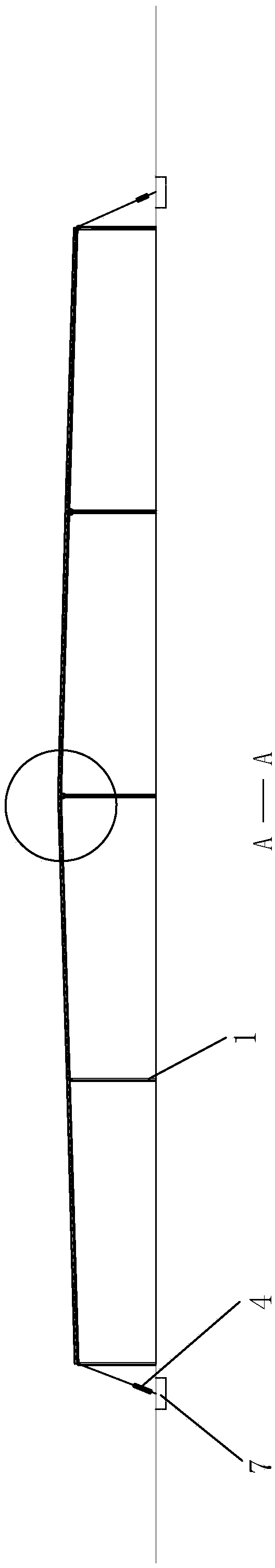

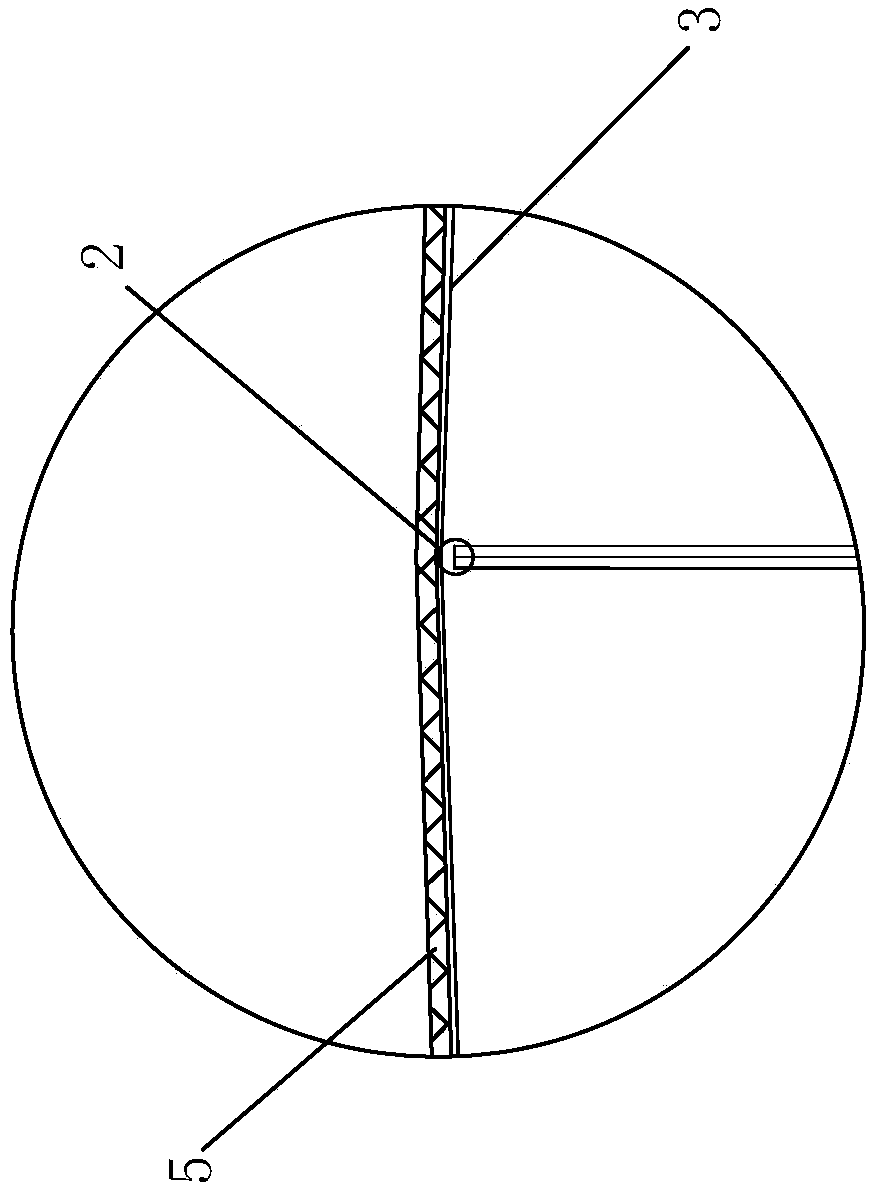

[0029] see Figure 1 to Figure 4 As shown, a light-weight bulk cargo warehouse disclosed by the present invention includes steel columns 1, pulleys 2, steel wire ropes 3, elastic adjusters 4 and dust-proof and air-permeable nets 5. Steel columns 1 are erected on the ground, and several steel columns 1 are arranged in horizontal and vertical rows. A pulley 2 is installed on the top of the steel column 1. The same wire rope 3 is wound on the pulley 2 at the top of the same horizontal row of steel columns 1, and the two ends of the wire rope 3 are fixed on the ground, and the wire rope 3 is equipped with a tightness adjuster 4 (the tightness adjuster 4 can be purchased on the market as required. specified model). A dust-proof air-permeable net 5 is installed between two steel wire ropes 3 on two adjacent horizontal steel columns 1, and the dust-proof air-permeable net 5 has two layers of metal mesh 51,52 and a middle layer of dust-proof material 53, two layers of metal mesh 51,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com