Air-permeable sound-permeable waterproof membrane

A waterproof membrane, waterproof breathable membrane technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc. Impregnation, improve the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

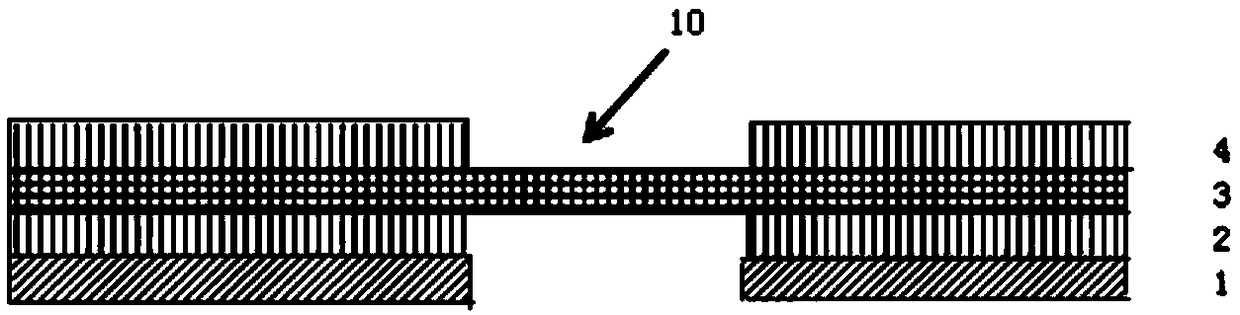

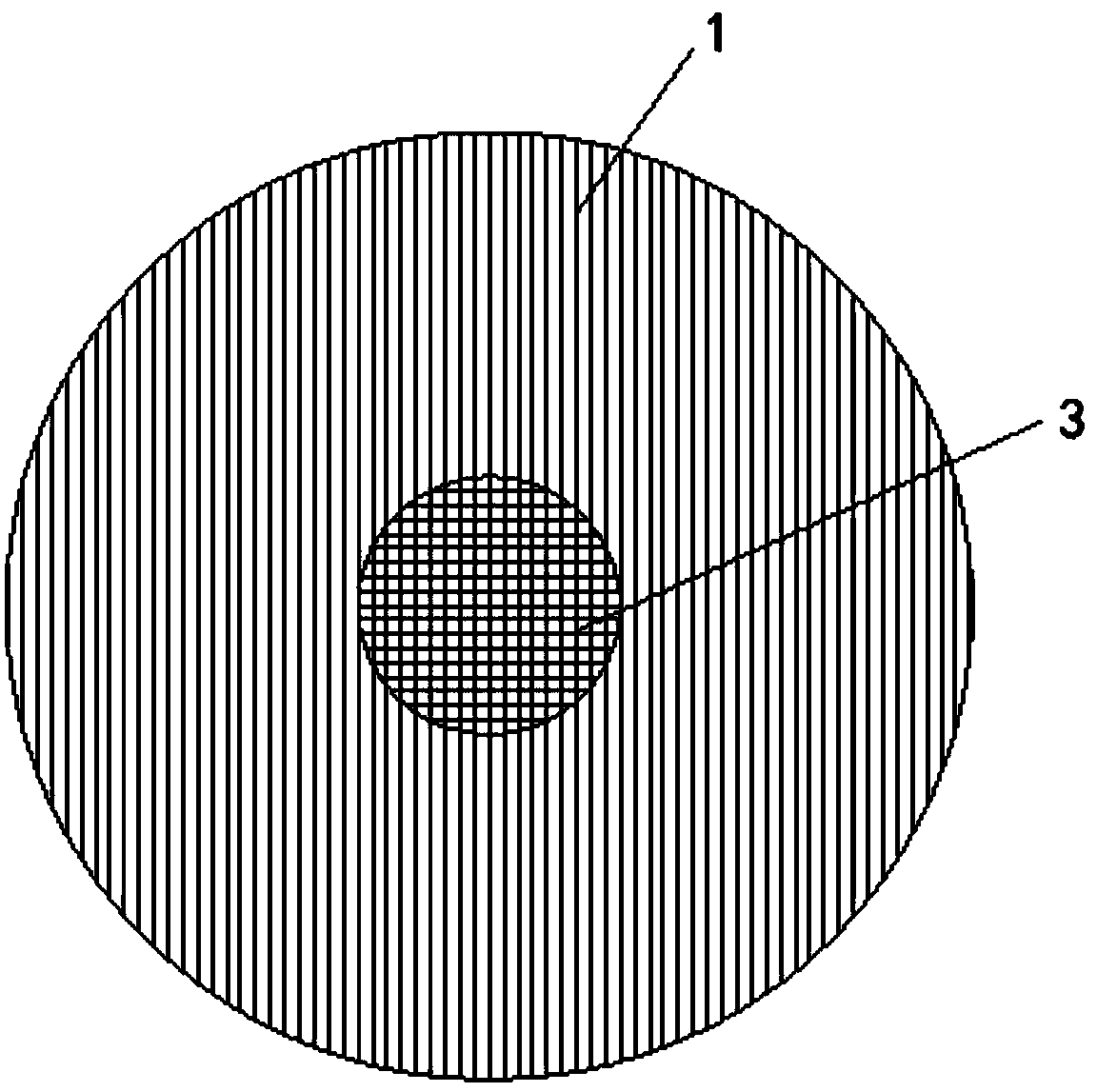

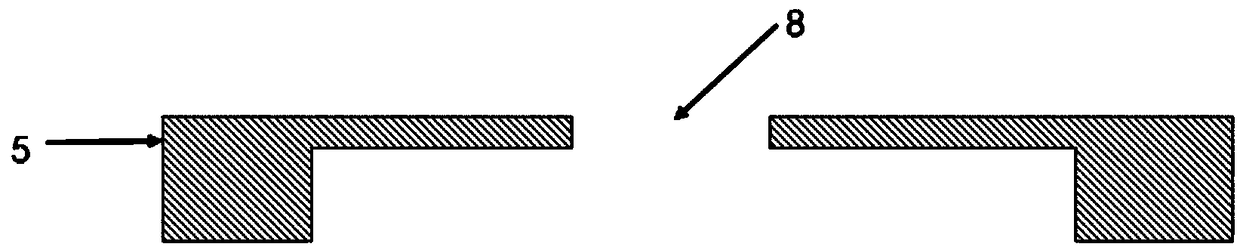

[0044] Such as Figure 1-5 Air-permeable sound-permeable waterproof membrane, including housing 5 and pressing plate 7 installed in housing 5, waterproof and breathable diaphragm assembly; the top of said housing 5 is provided with a first through hole 8; said pressing plate 7 and housing 5 The position where the first through hole 8 is provided on the top constitutes a closed area, and the pressure plate 7 is in sealing connection with the housing 5; Corresponding, and the two are connected; a pressure support 11 is provided between the pressure plate 7 and the inner surface of the bottom of the housing 5; the pressure support 11 is a rib, a circuit board, a filler block or an electronic One of the components, the pressure support member 11 in this embodiment is a rib; and the pressure support member 11 can be fixedly connected with the housing 5 and the pressure plate 7 by means of gluing, welding, etc., or can be detachably connected by snap-fitting or the like. , as long ...

Embodiment 2

[0058] The air-permeable, sound-permeable and waterproof membrane described in this embodiment is basically the same as that in Embodiment 1, except that:

[0059] Such as Figure 6-8 As shown, the top of the housing 5 is flat; the longitudinal section of the pressure plate 7 is L-shaped at both sides of the second through hole 9, and the waterproof and breathable diaphragm assembly is installed in the pressure plate 7; The third adhesive layer 6 of the body 5.

[0060] The upper surface of the inner bottom of the pressing plate 7 is bonded to the lower surface of the waterproof and breathable membrane assembly through the fourth adhesive layer 12, that is, the support part 1 is bonded, and the fourth adhesive layer 12 is located between the first through hole 8 and the second The peripheral area of the passage that through hole 9 forms; The depth of pressing plate 7 inside and the thickness summation of the 3rd bonding glue layer 6 equal the total thickness of waterproof b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com