Patents

Literature

43results about How to "Wind resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

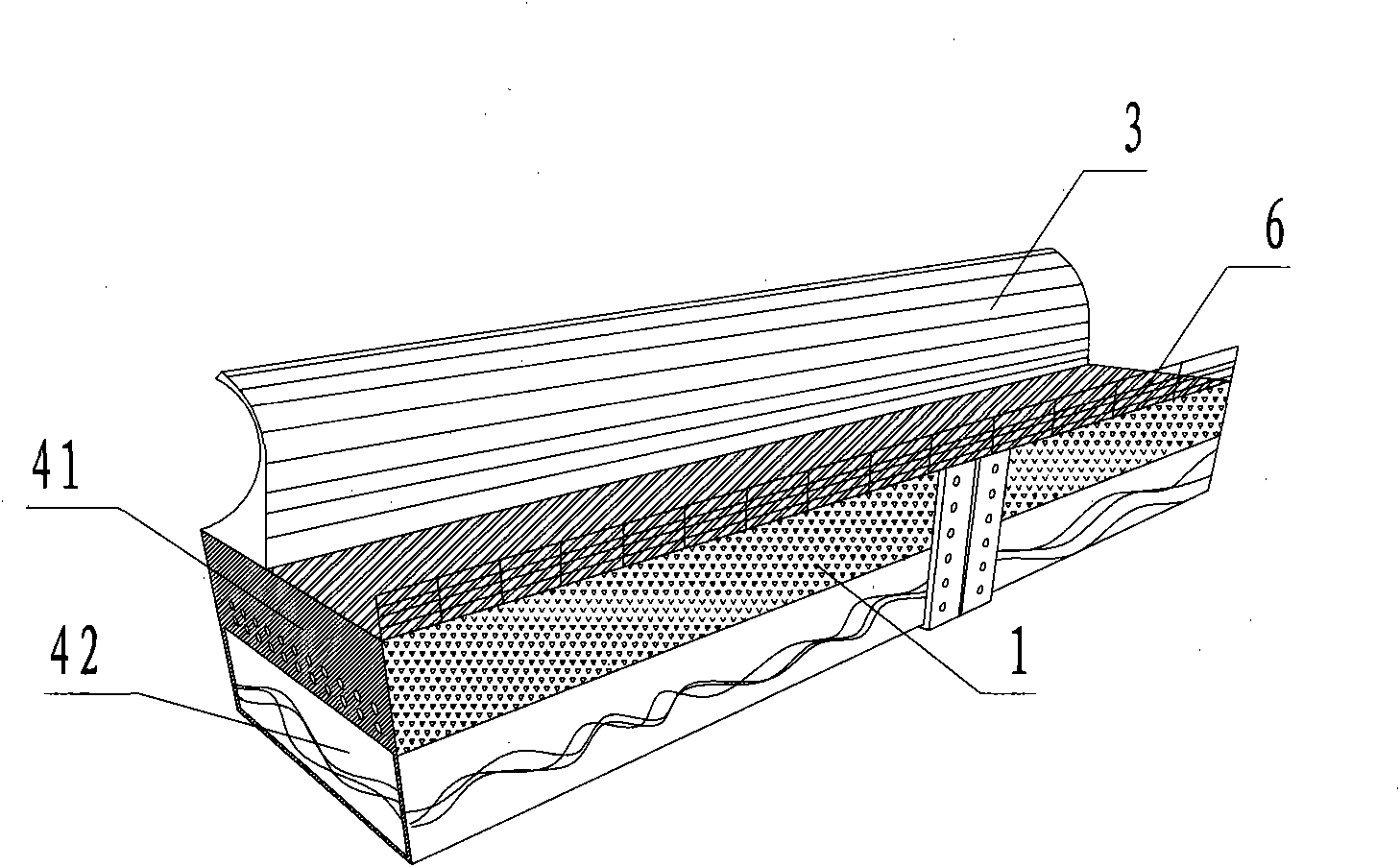

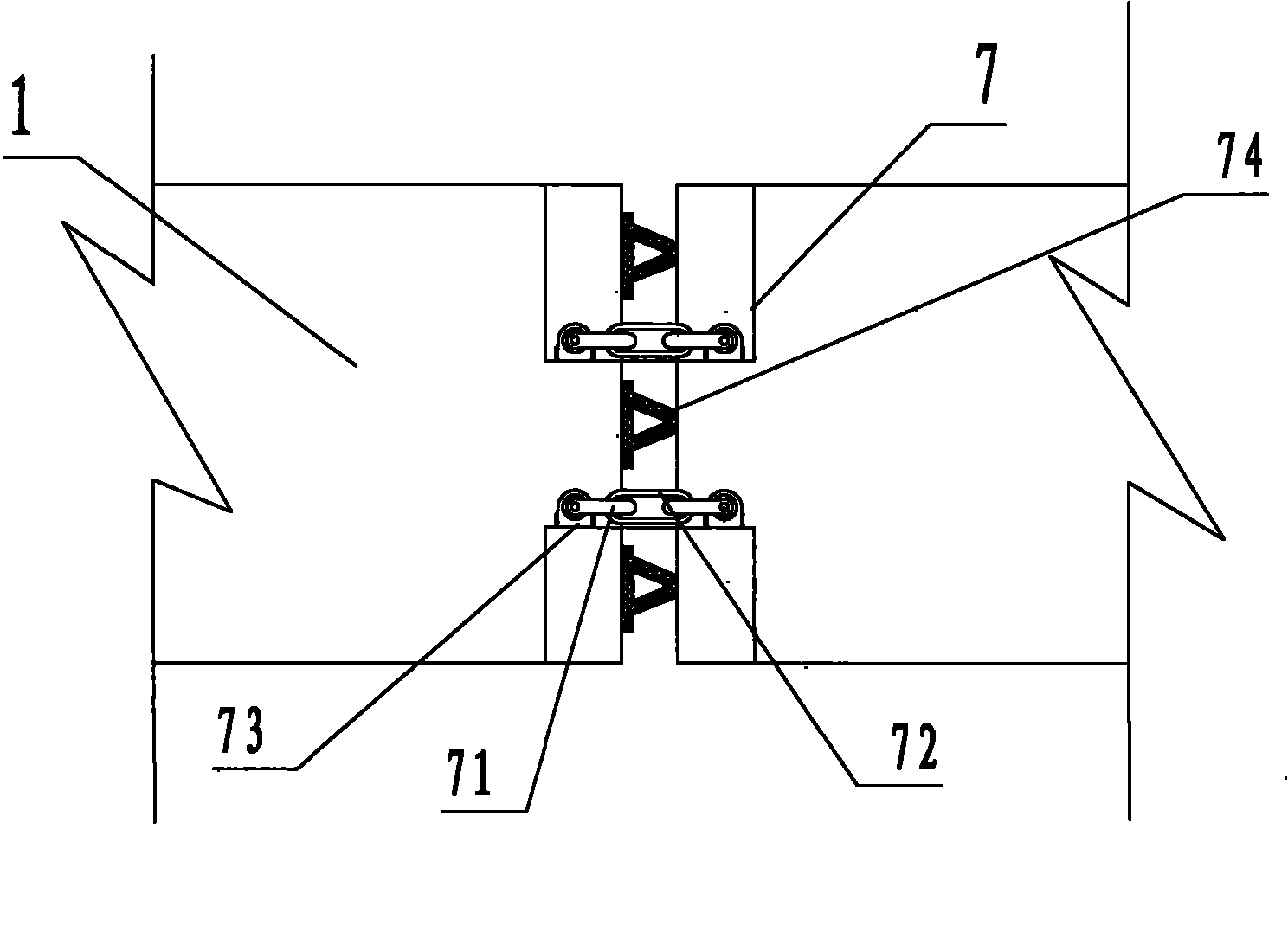

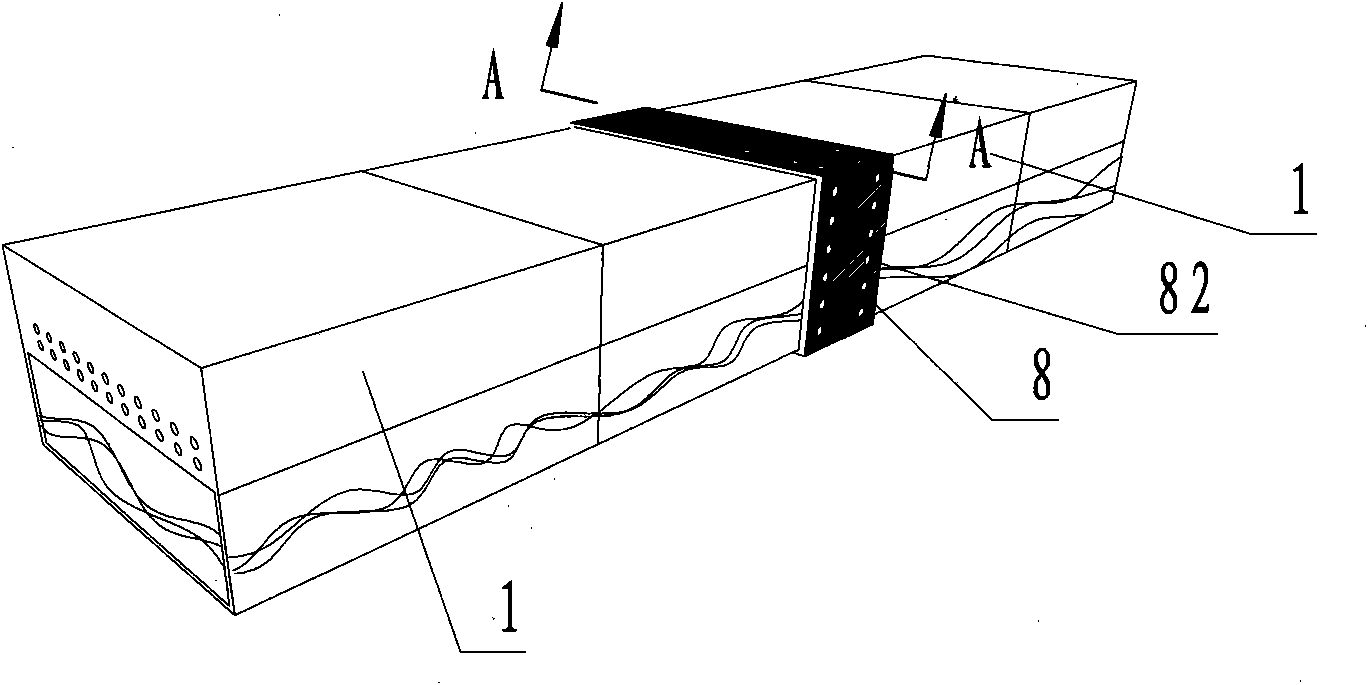

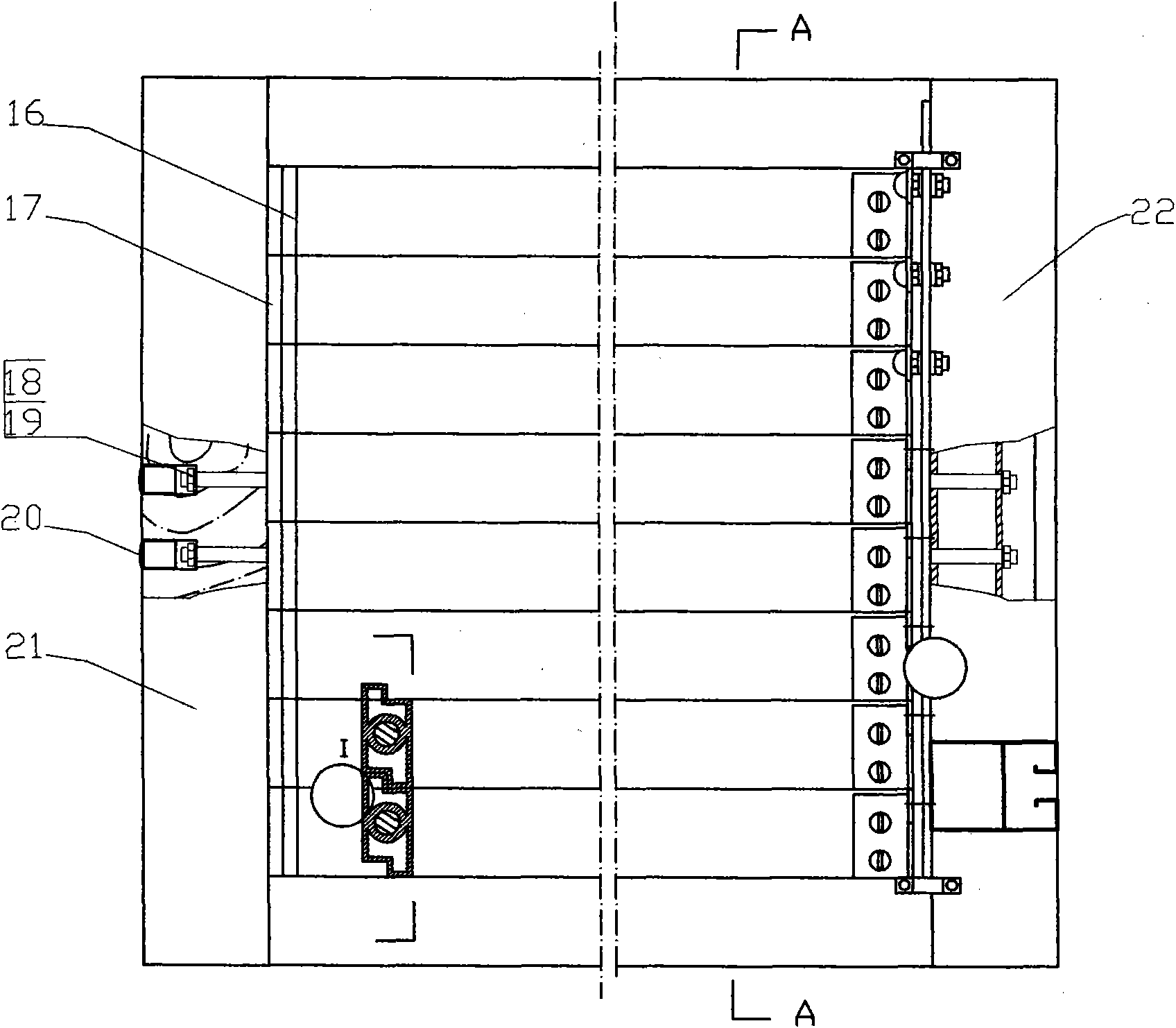

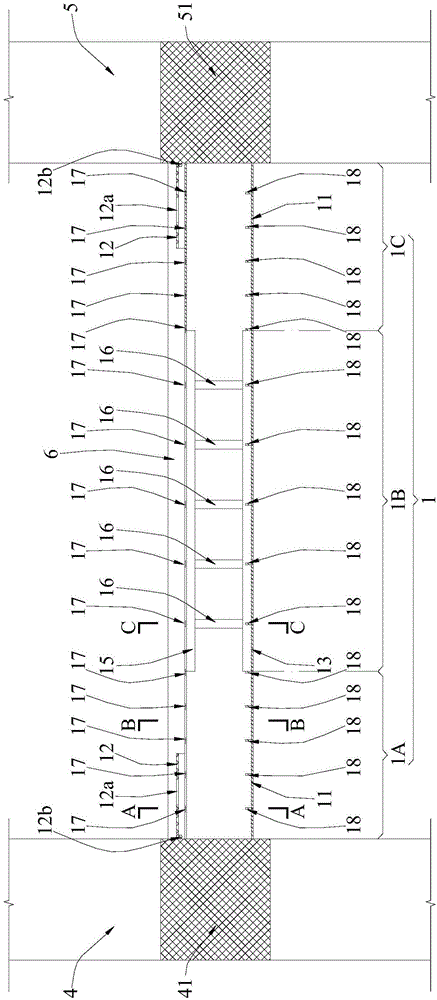

Semi-submersible type multifunctional jetty

InactiveCN101850834AExpand to benefit the societyGood sea living environmentBreakwatersQuaysEngineeringFishing

The invention discloses a semi-submersible type multifunctional jetty, comprising one or more semi-submersible type steel box bodies mutually connected together. The lower part of each box body is provided with an anchoring locating device, and a wave wall is arranged in the longitudinal direction at the upper part of the box body. The box body is internally provided with an intermediate deck dividing the box body into an upper layer and a lower layer, wherein the upper layer is a functional box, and the lower layer is a snorkeling box. The lower layer of the box body is provided with a snorkeling device, and one end part of the box body is also provided with a shore coupling device. The invention has the advantages that the adopted semi-submersible type jetty has low manufacturing cost, short construction period, convenient construction and safe use, can effectively prevent geological disasters and avoid the damage caused by earthquakes and surge, does not change the ocean attribute and can utilize a platform on the surface of the box body as a floating dock and a hydrophilic leisure and entertainment occasion for fishing and the like.

Owner:许是勇

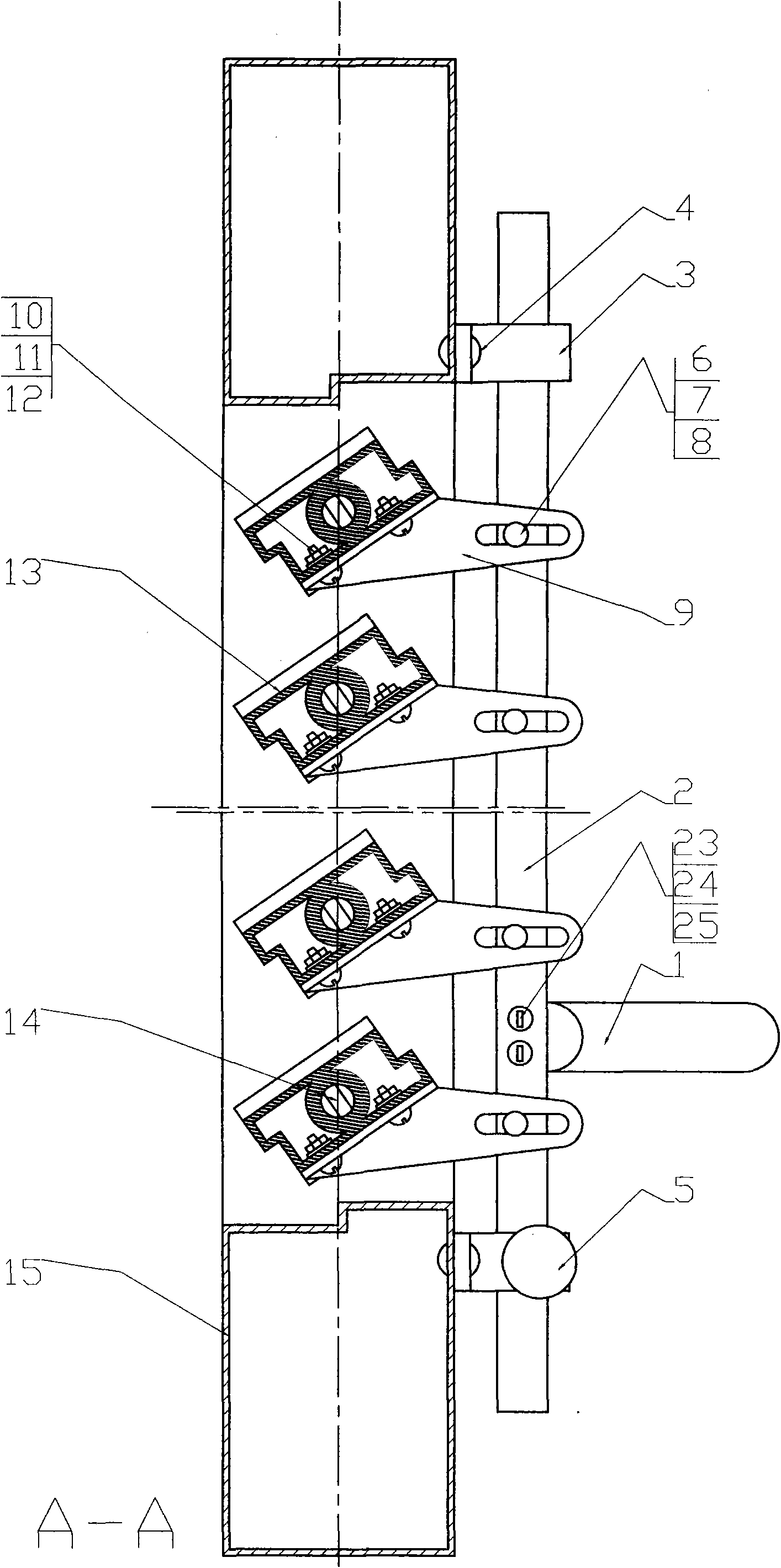

Multifunctional louver

InactiveCN101871309AAnti-theftWind resistantShutters/ movable grillesSpecial door/window arrangementsPush pullEngineering

The invention relates to a multifunctional louver mainly comprising a push-pull handle, a slide bar, a slide bar support, locking screws, a swing member, hollow blades, a double-end screw rod, wool top clips, sealing wool tops, a door and window frame and the like. The hollow blades have a long strip shape. Two narrow surfaces are asymmetric laps with perforations in the center. A plurality of ripples are arranged on hollow inner walls. The double-end screw rod has a long round strip shape, and both ends respectively have one section of thread. A plane of the wool top has two T-shaped grooves. Two narrow sides are asymmetric laps with a hole in the center and a left and a right clip feet on the back.

Owner:刘明曦

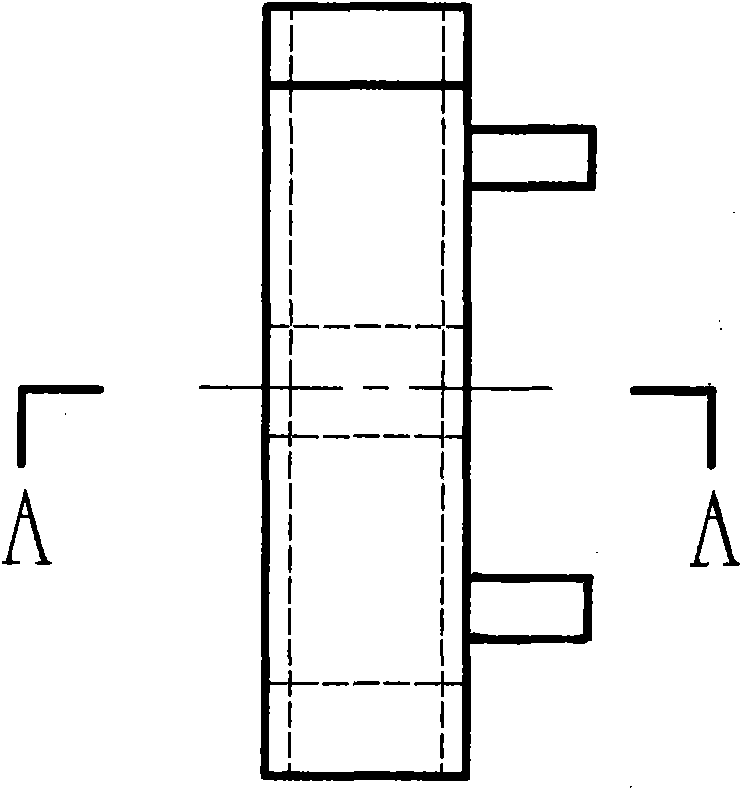

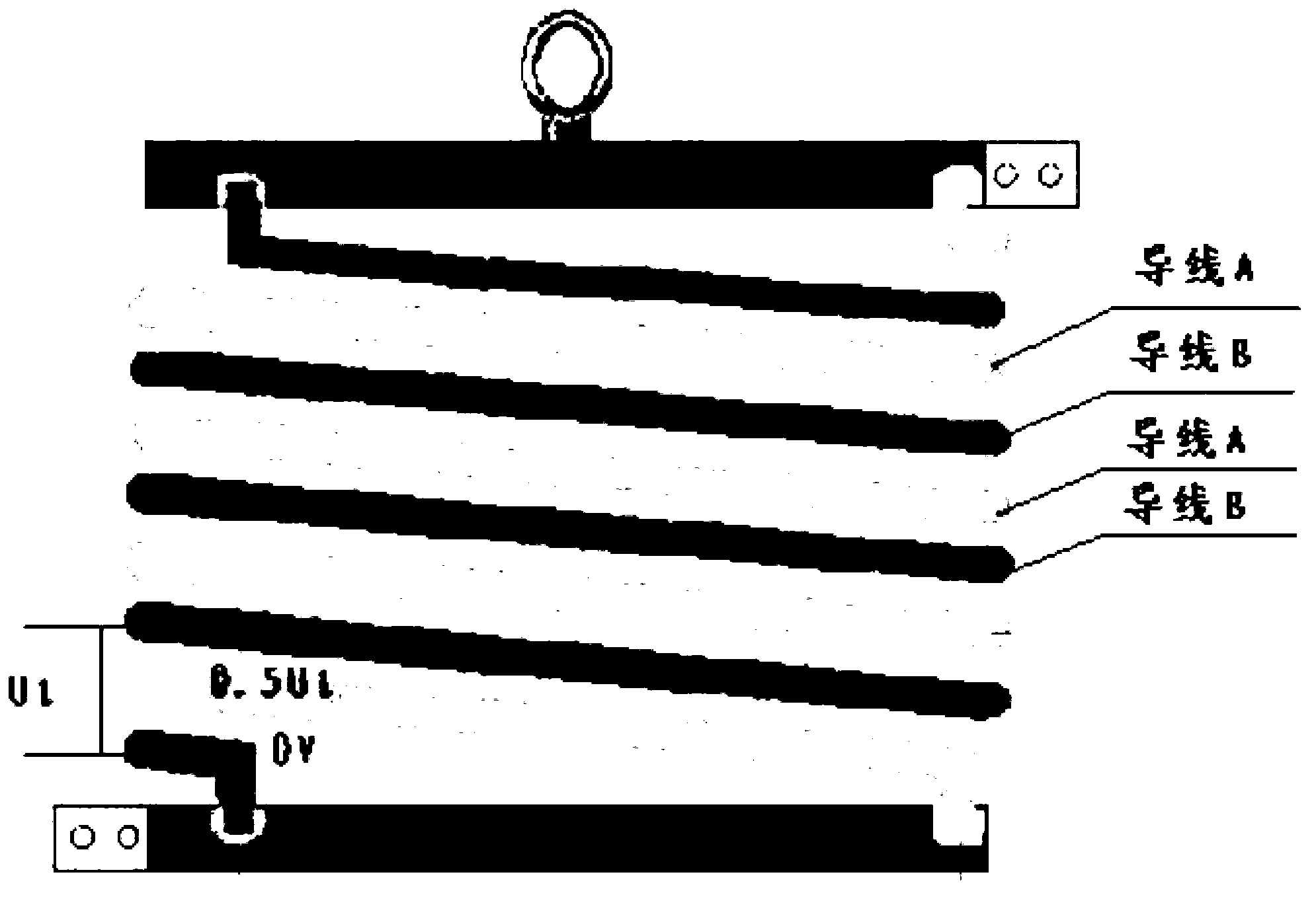

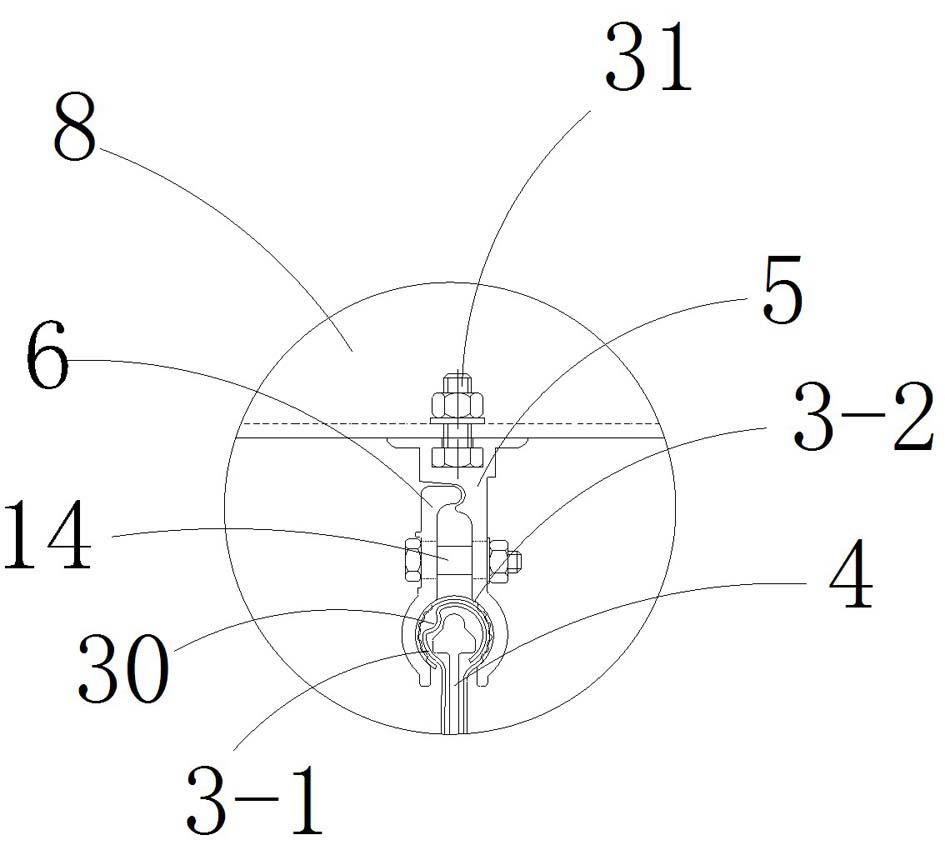

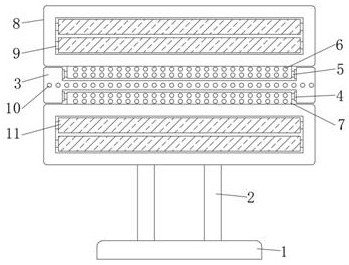

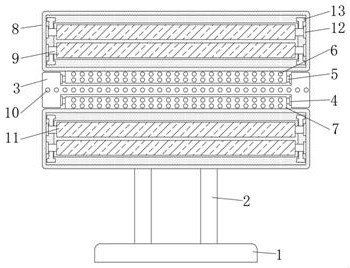

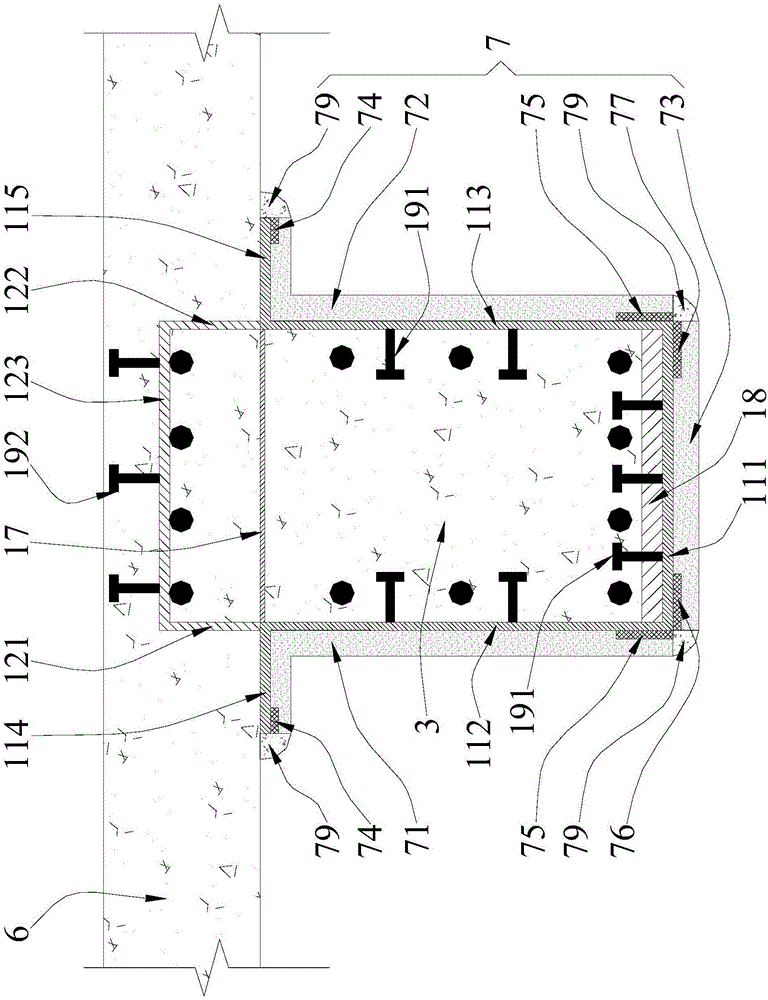

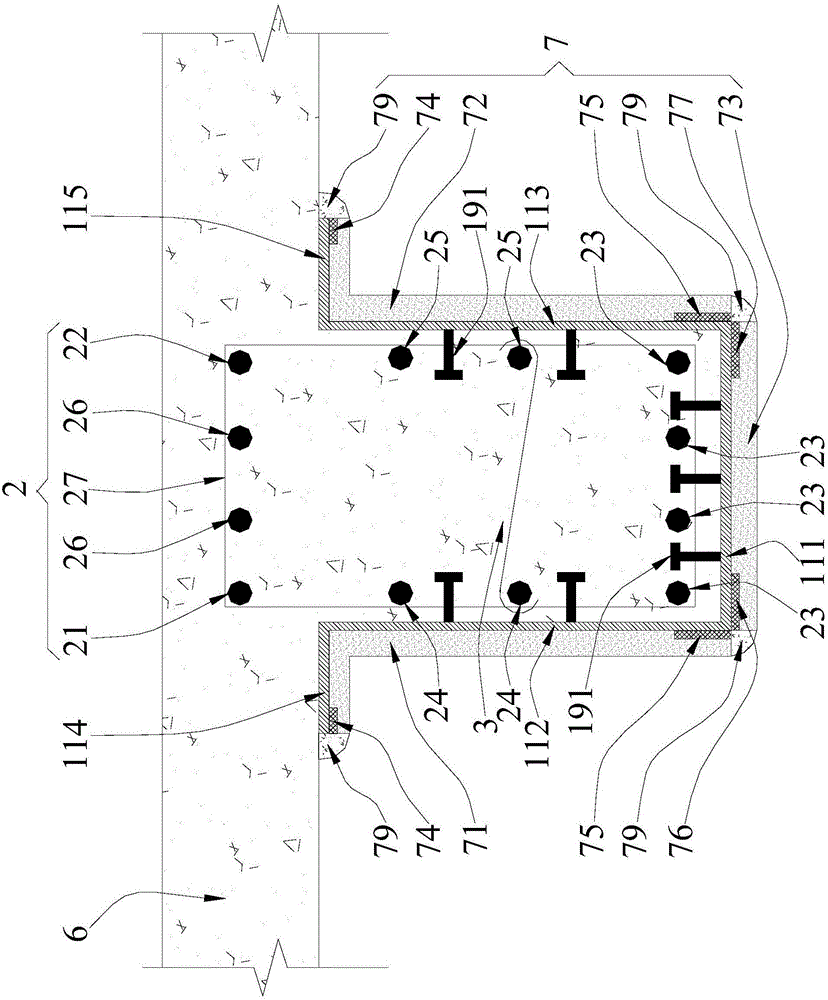

Extra-high-voltage dry hollow smoothing reactor

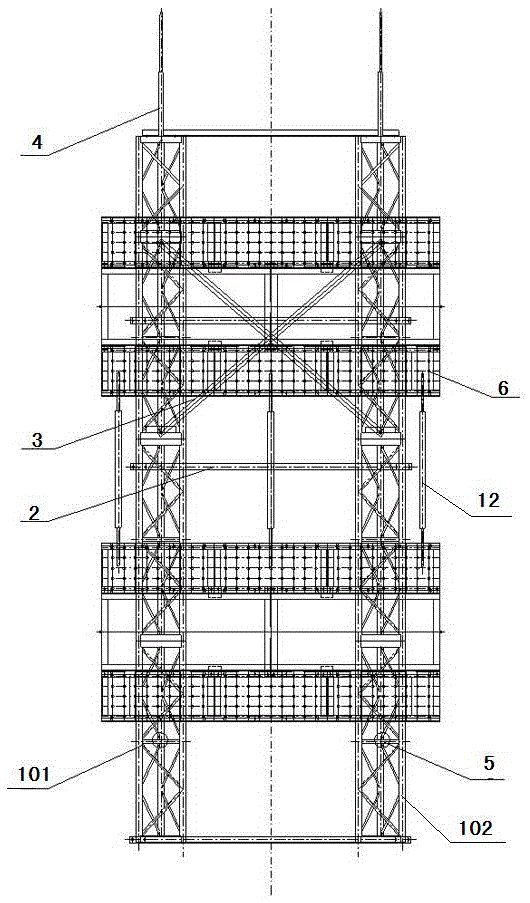

InactiveCN103187143ASolve electric field distortionIncrease the support heightTransformers/inductances coolingTransformers/inductances coils/windings/connectionsPower flowHigh-voltage direct current

The invention provides an extra-high-voltage dry hollow smoothing reactor, comprising a reactor coil, an insulating bracket, a rain-proof noise-reducing device, an arrester and an electric field shielding piece, wherein the insulating bracket is supported at the bottom of the reactor coil; the rain-proof noise-reducing device is wrapped outside the reactor coil; the arrester is connected with the reactor coil in parallel; the insulating bracket comprises a plurality of supporting insulators and at least one horizontally arranged insulator tie bar platform; each supporting insulator comprises a plurality of insulators which are connected in series through end part flanges; and the insulator tie bar platform is connected with the end part flanges of the insulators at the same level of each supporting insulator, so that the insulators at the same level have the same electric potential. The coil of the extra-high-voltage dry hollow smoothing reactor can meet the requirements of a + / - 800 kv or + / - 1,100 kv direct current power transmission project on voltage, current and impact level and can meet the requirements of an extra-high-voltage direct current power transmission project on ground insulating level and seismic intensity.

Owner:BEIJING POWER EQUIP GRP +1

Method for producing waterproof moisture permeable fabric

The invention discloses a method for producing a waterproof moisture permeable fabric with functions of moisture permeating and water proofing, which comprises the following steps: firstly, soaking a fabric into a soaking groove filled with Teflon waterproof agent for 1 to 2 minutes, and then drying and baking the soaked fabric; next, calendering the fabric, and then coating bottom adhesive on the calendered fabric surface; and finally, coating surface adhesive on the surface of the surface of the fabric bottom adhesive, wherein the bottom adhesive consists of 100 portions of polyfluortetraethylene, 10 to 15 portions of toluene, 10 portions of polyacrylate, 3 to 5 portions of cross-linking agent, and 1 to 2 portions of accelerating agent in portion by weight; and the surface adhesive consists of 100 portions of polyfluortetraethylene, 10 to 15 portions of toluene, 10 portions of polyacrylate, and 2 portions of smooth anti-sticking agent in portion by weight.

Owner:石狮市亿祥染整有限公司

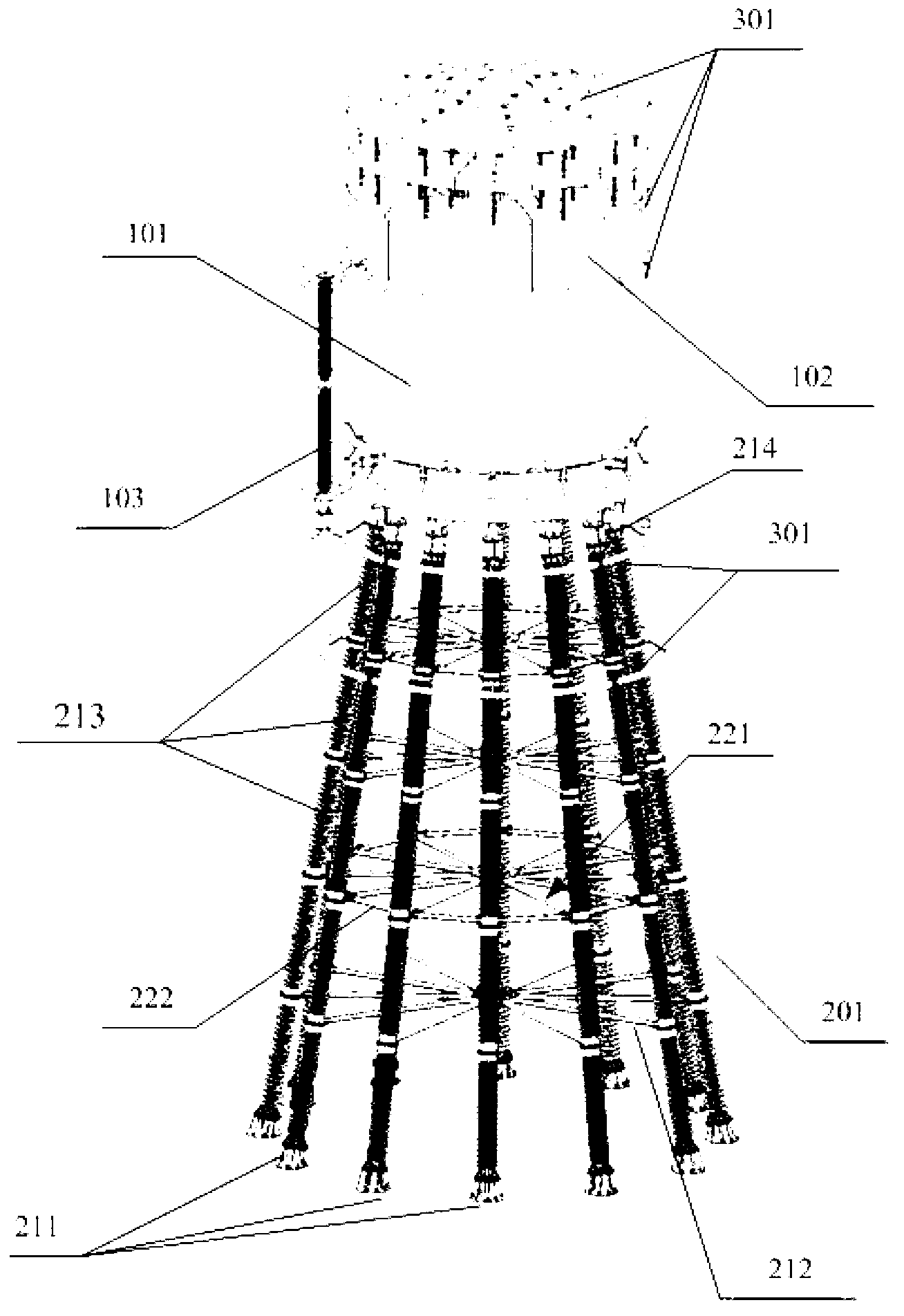

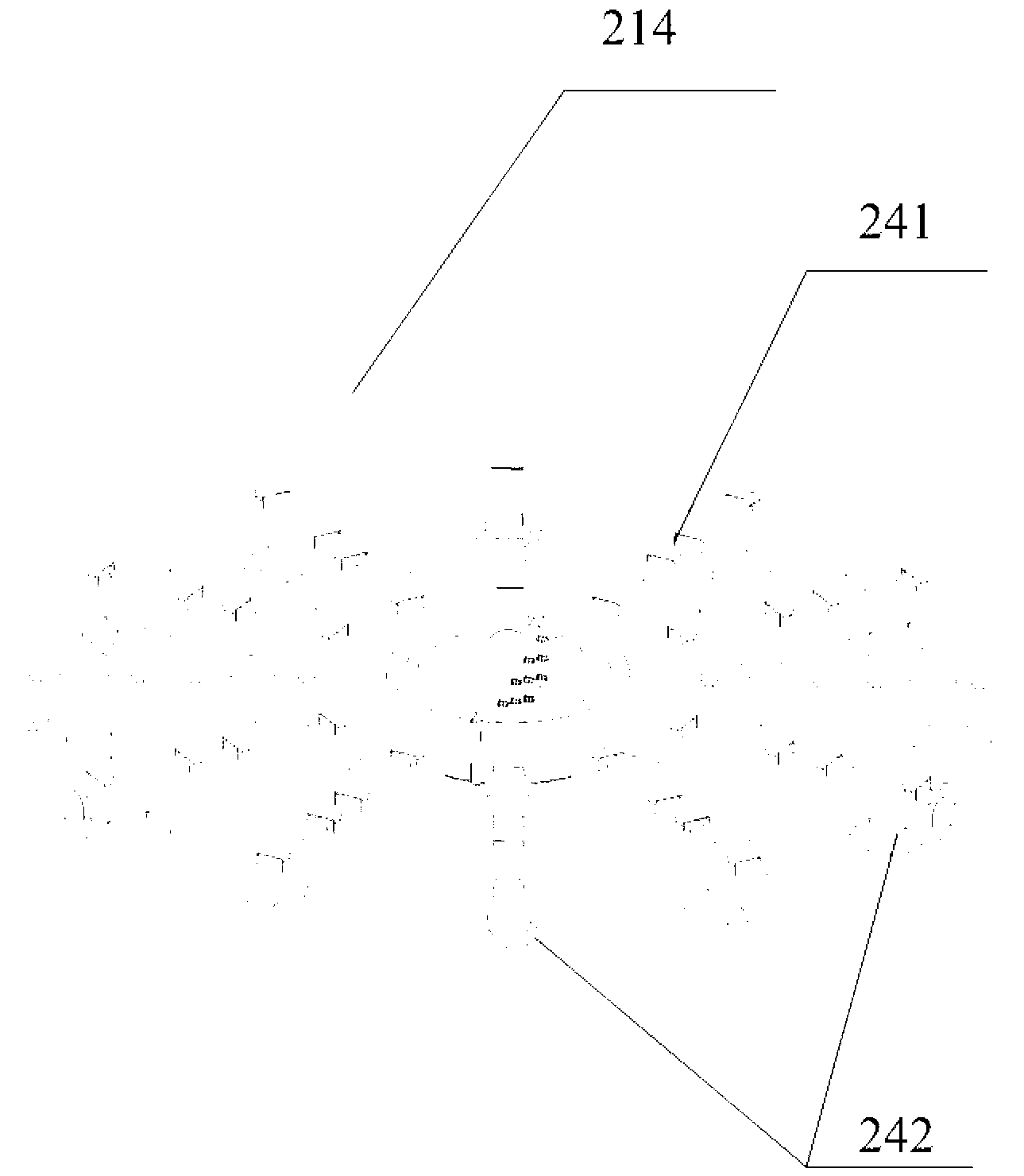

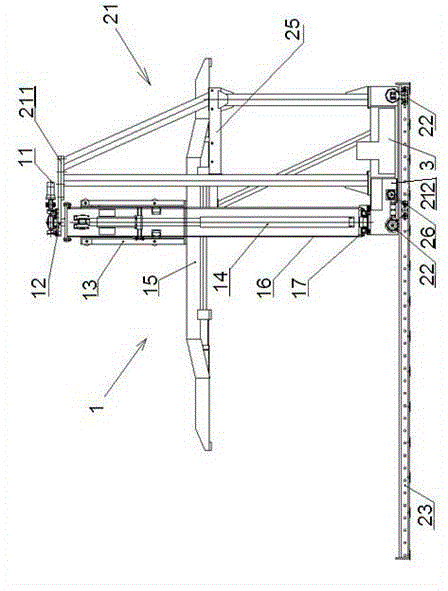

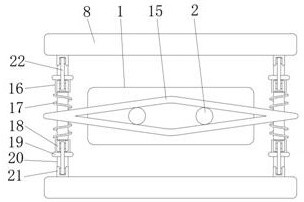

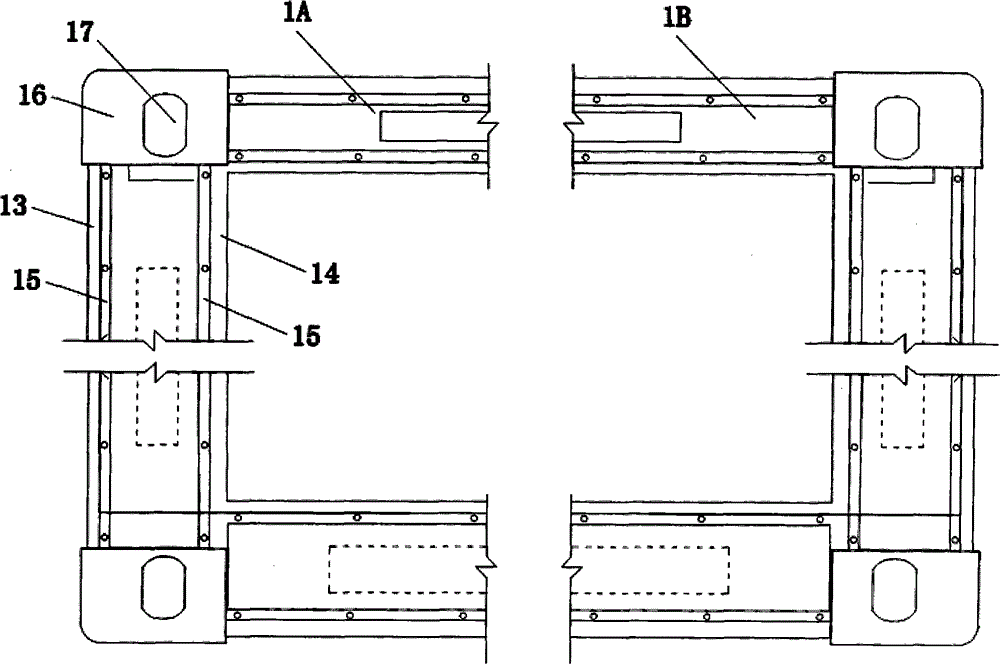

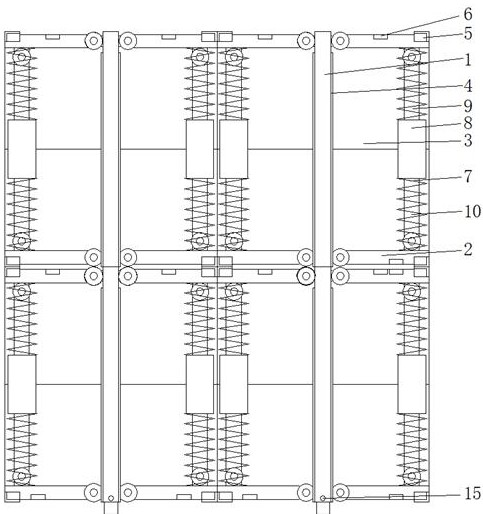

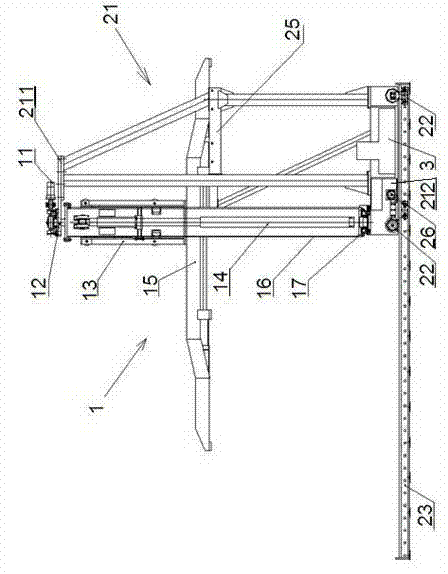

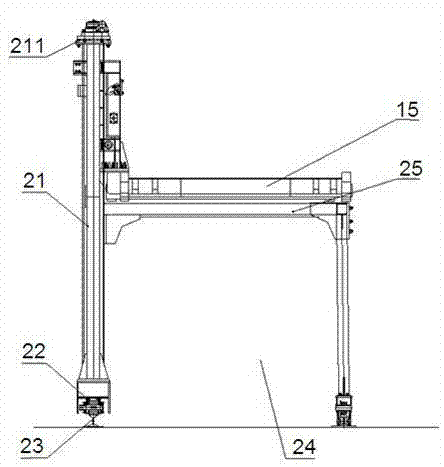

Single-side hydraulic drive type stereoscopic frame parking stall

The invention provides a single-side hydraulic drive type stereoscopic frame parking stall and mainly solves problems that existing parking stalls occupy large areas and installation and operation are complicated. The single-side hydraulic drive type stereoscopic frame parking stall is characterized in that the cross section of a garage-shaped frame is in an h shape; traveling wheels are installed on lower portions of side edges and travel on the ground track; a lifting slewing device installed on a stand column frame comprises a slewing stand column, an upper slewing support and a lower slewing support, the slewing stand column is installed between the upper slewing support and the lower slewing support, the upper slewing support and the lower slewing support are fixed on an upper cross beam and a lower cross beam of the stand column frame respectively, and a hydraulic slewing driving device which drives the slewing stand column to slew is installed on one slewing support; and a lifting sliding sleeve driven by a hydraulic cylinder is sleeved on the slewing stand column, and a vehicle carrying table board is fixed at the lower end of the lifting sliding sleeve. The single-side hydraulic drive type stereoscopic frame parking stall has the advantages that by means of a frame type main body and single-side hydraulic drive, the stereoscopic frame parking stall is simple in structure.

Owner:阜新工大科技发展有限公司

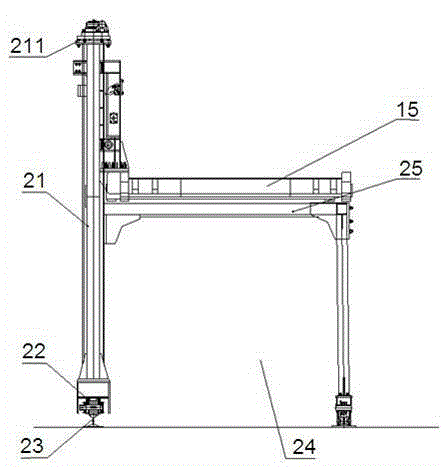

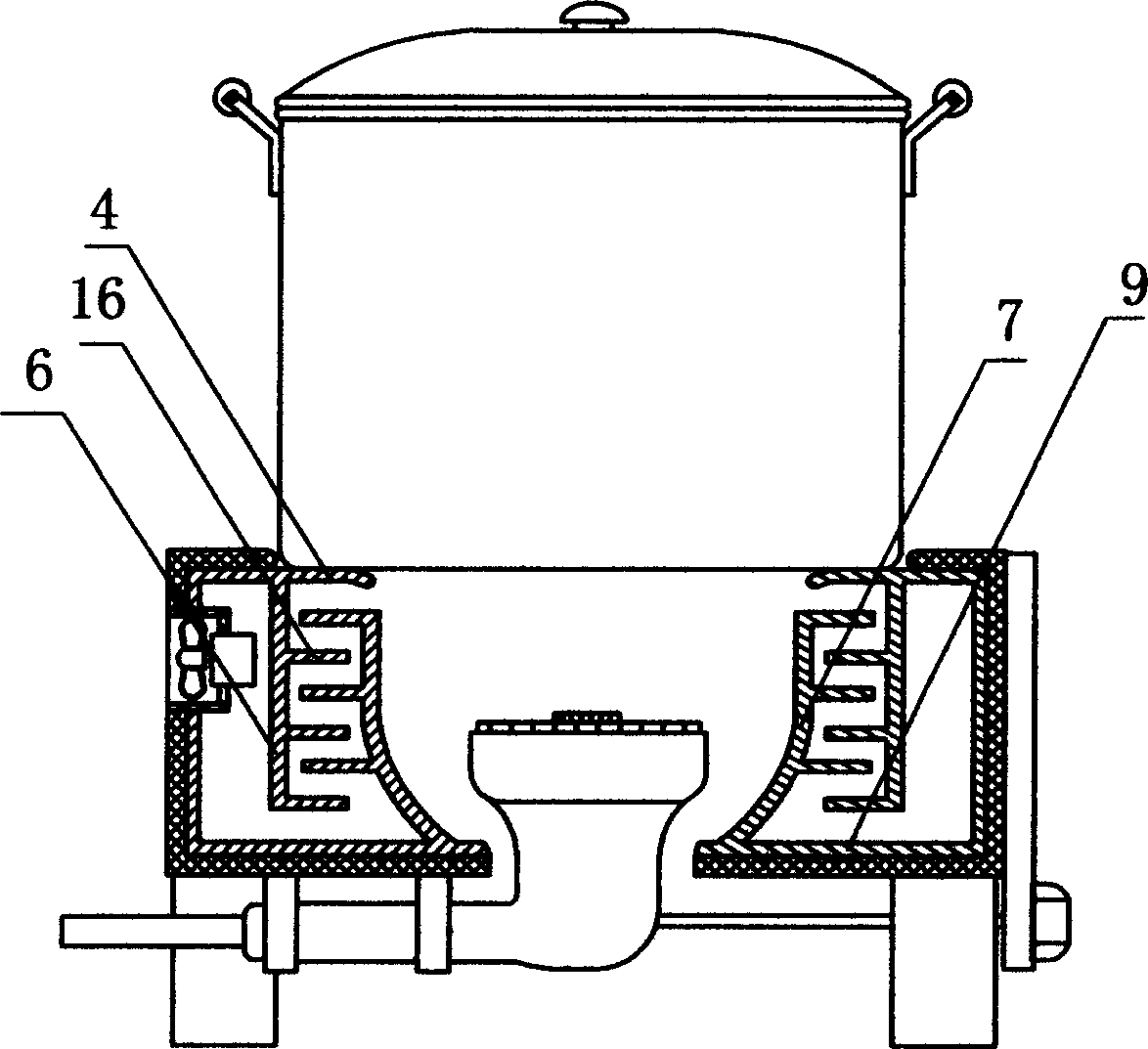

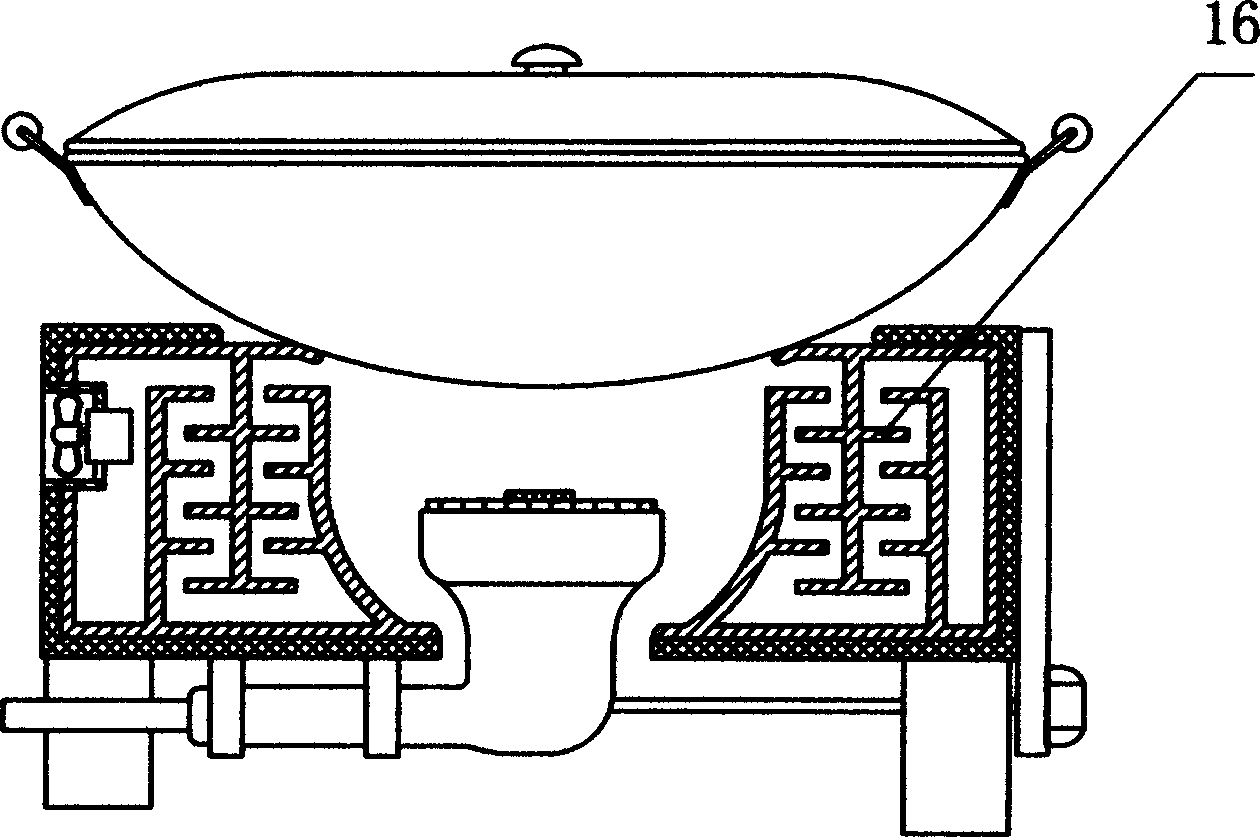

High efficiency energy saving gas range

InactiveCN1858501AFierce firepowerAvoid churnDomestic stoves or rangesLighting and heating apparatusCombustorHigh energy

The high efficiency energy saving gas range includes a combustor, a hearth, and a range body. The combustor is located in the bottom of the hearth, and the range body has casing with furnace hole. Between the casing and the hearth plate, is one curved fume cavity with inlet located in the upper part of the hearth plate, outlet inside the casing and fume exhausting fan at the outlet. The present invention has high energy source utilizing rate and environment friendship.

Owner:吴国成

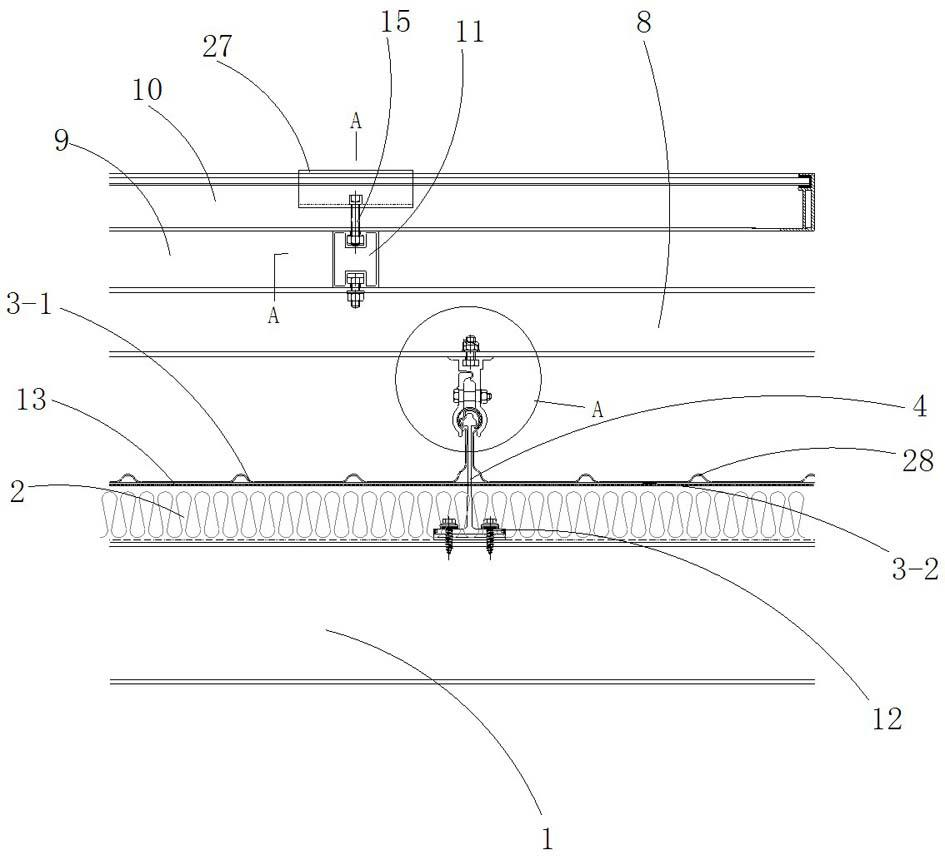

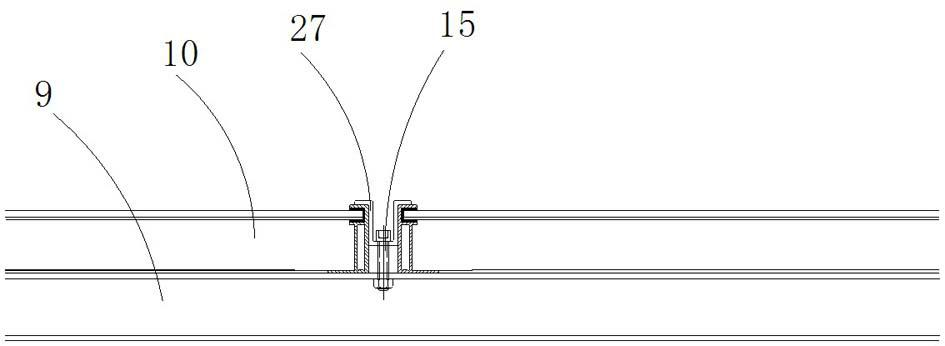

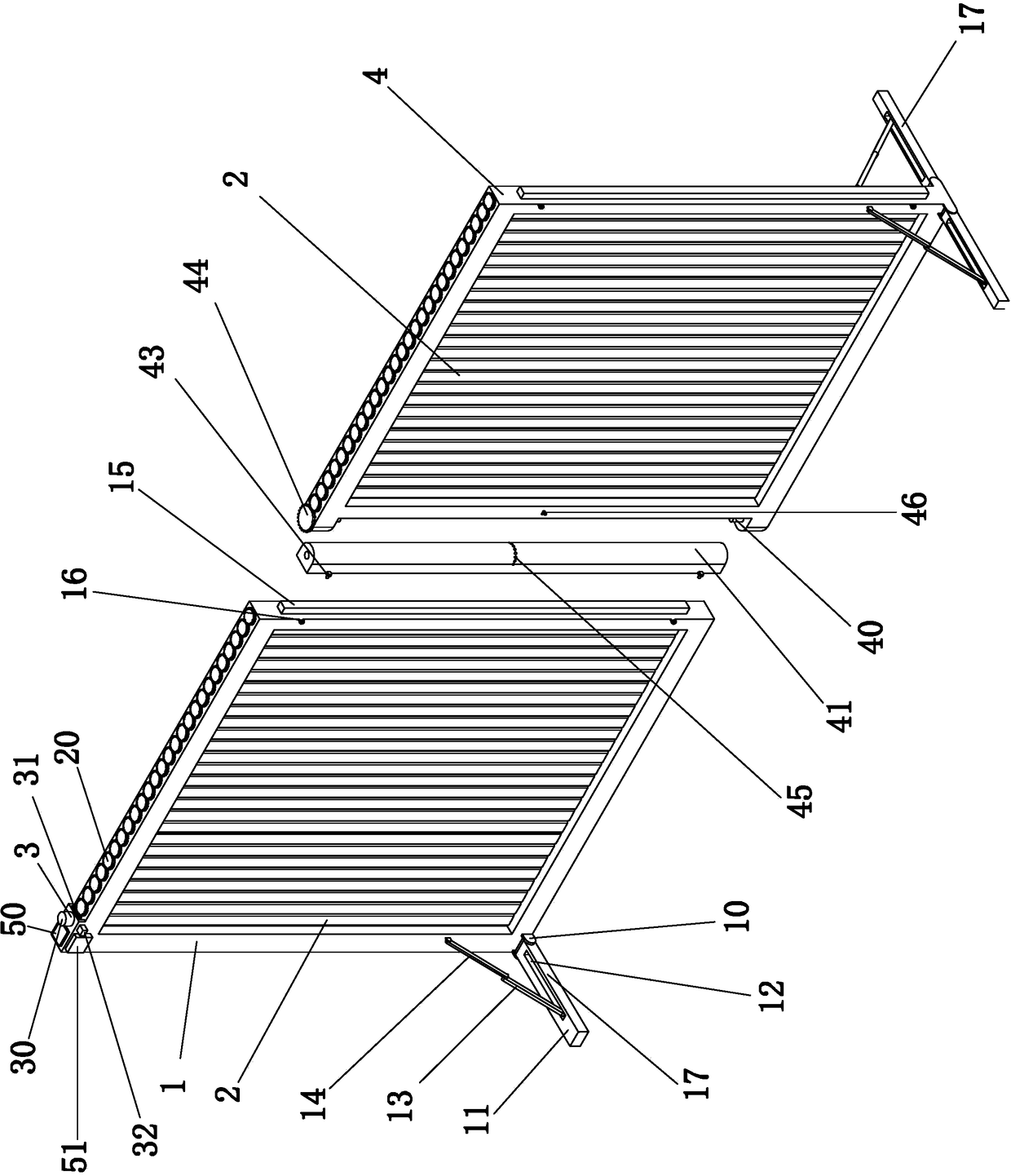

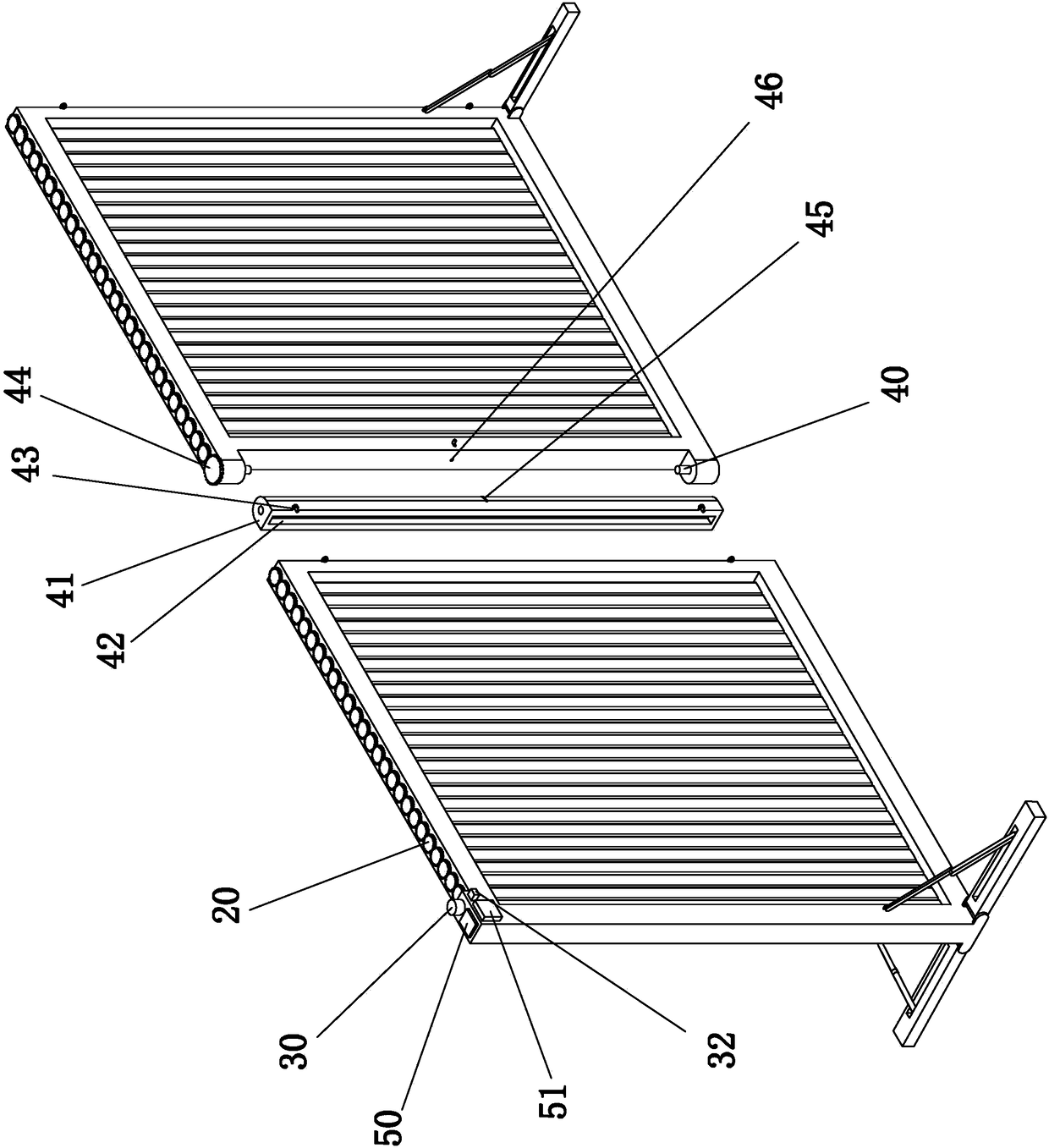

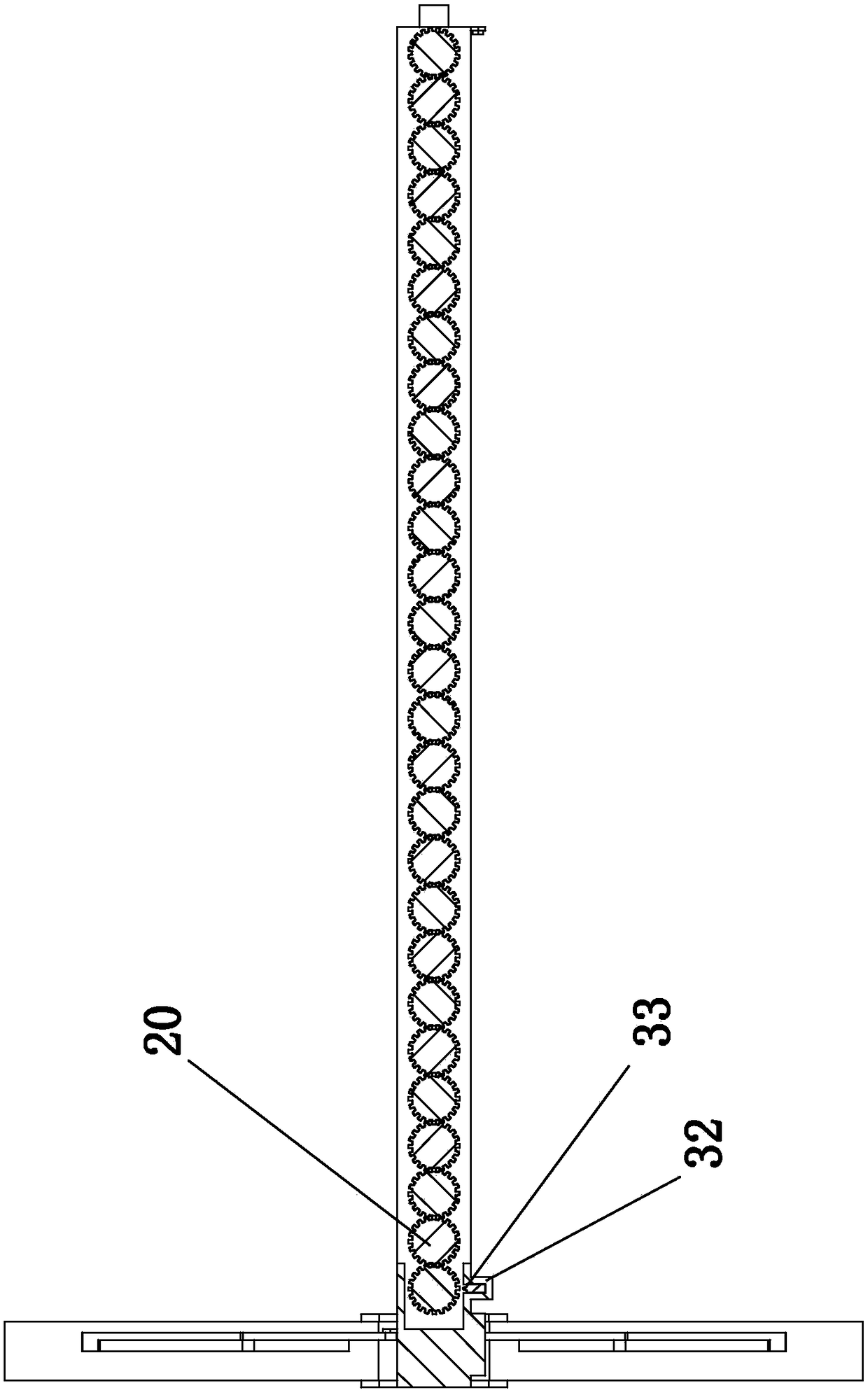

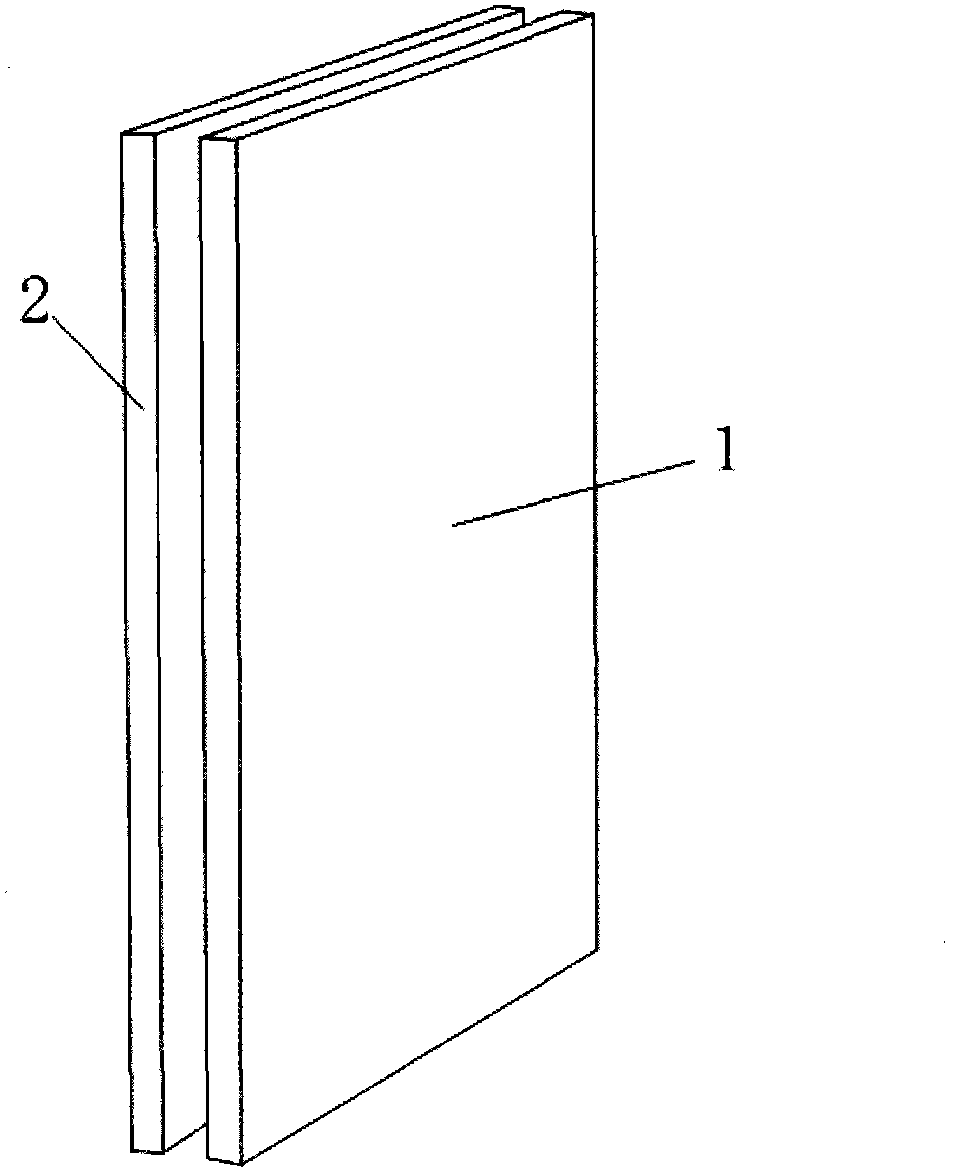

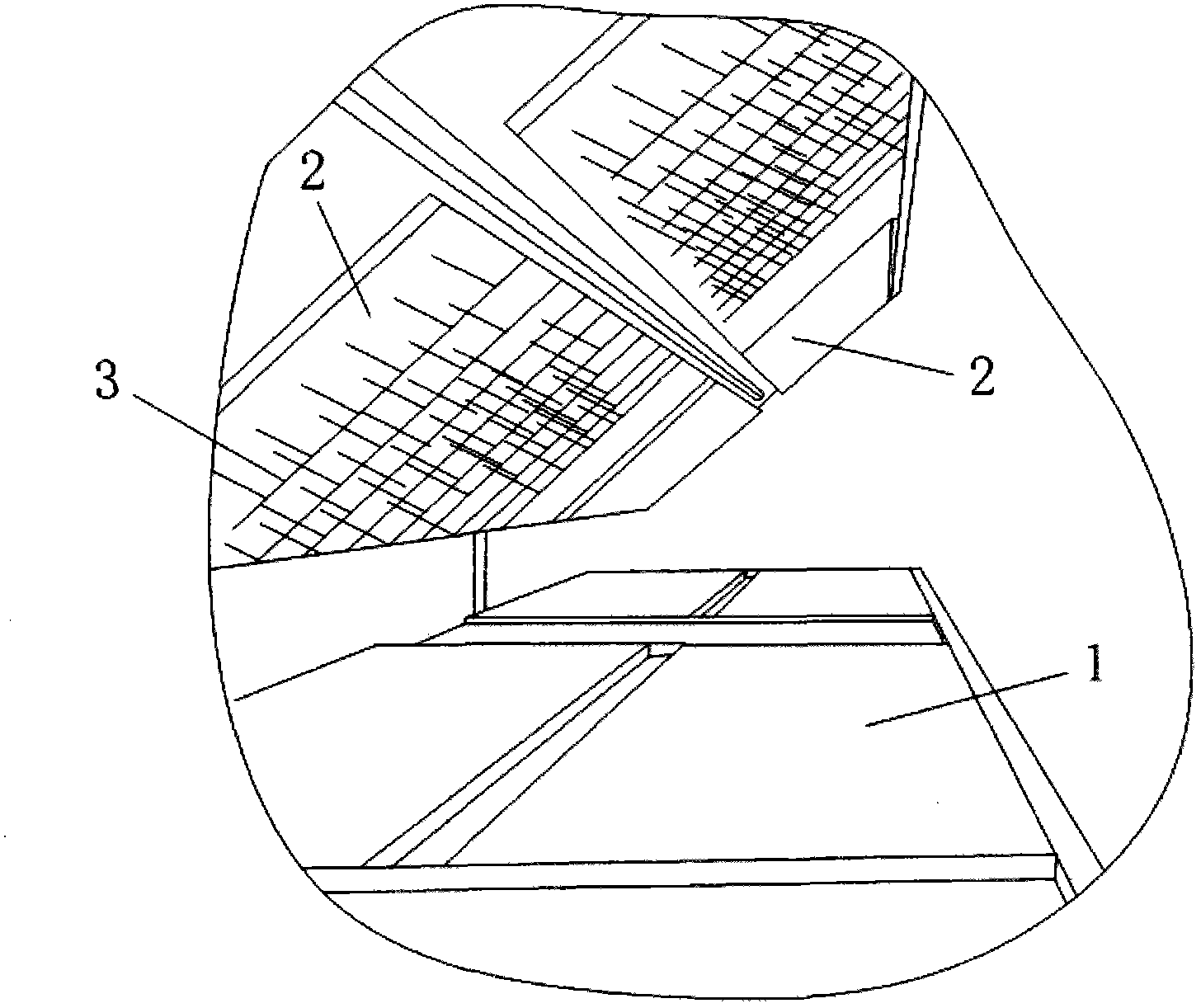

Connection node of metal proofing system for solar photovoltaic building and mounting method

ActiveCN102635210ATake advantage ofSimple structurePhotovoltaic supportsRoof covering using slabs/sheetsEngineeringPhotovoltaics

The invention relates to a metal proofing system, particularly relates to a connection node of a metal proofing system for a solar photovoltaic building and a mounting method, and belongs to the field of steel structures. An insulating layer is arranged on a secondary purline of a roof; a metal proofing plate is arranged on the insulating layer; the metal proofing plate is fixed through a spliced supporting strip; a clamping piece is arranged on the lateral wall of the lower end of a clamping base; the clamping piece and the clamping base form a clamping opening and clamp a spliced position; a skeleton is fixed above the clamping base; a guide groove purline is arranged on the skeleton; and a solar panel component is arranged on the guide groove purline. The connection node of the metal proofing system for the solar photovoltaic building and the mounting method are simple in structure and strong in supporting property, fully utilize solar energy resources and have wind resistance.

Owner:浙江东南网架股份有限公司

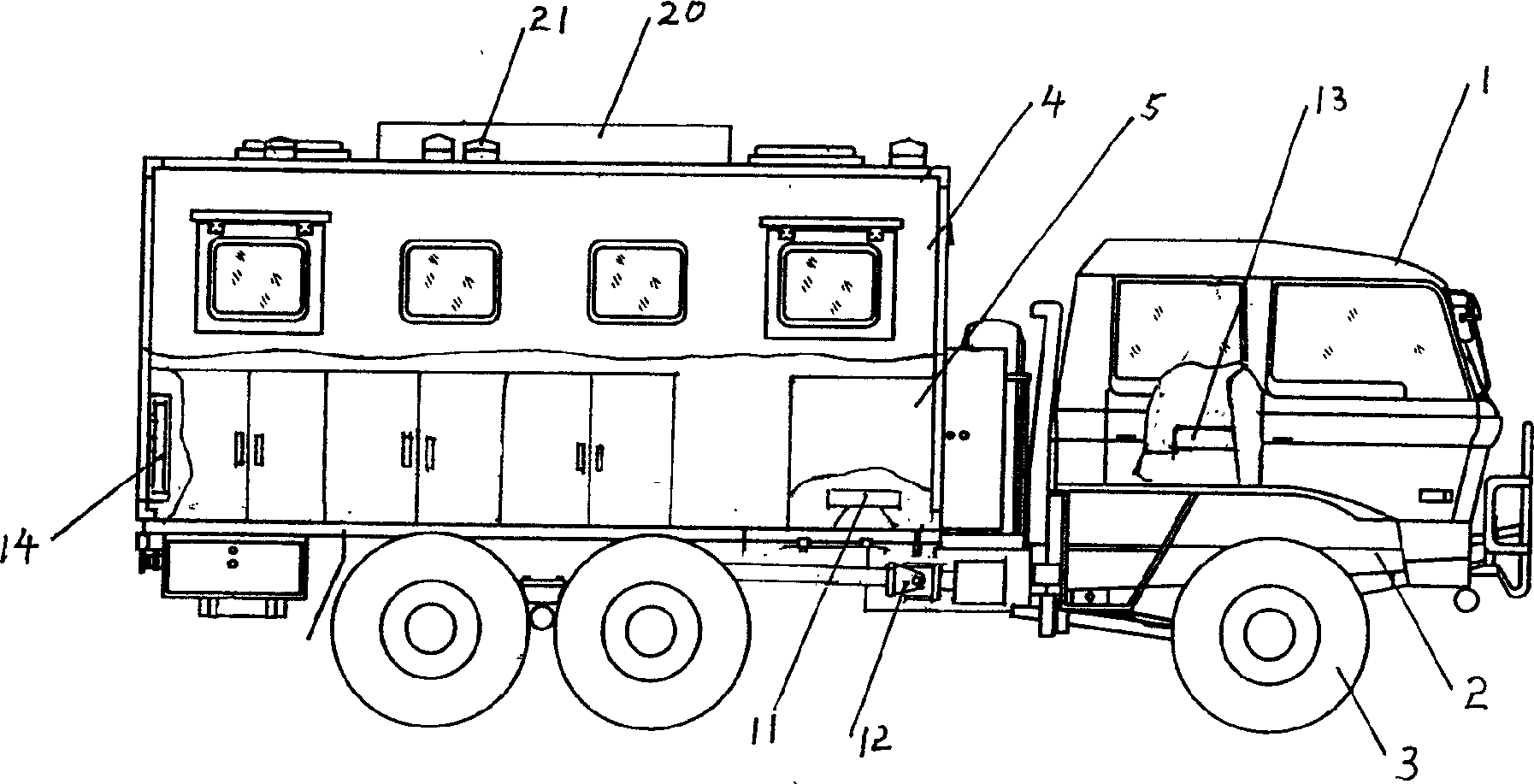

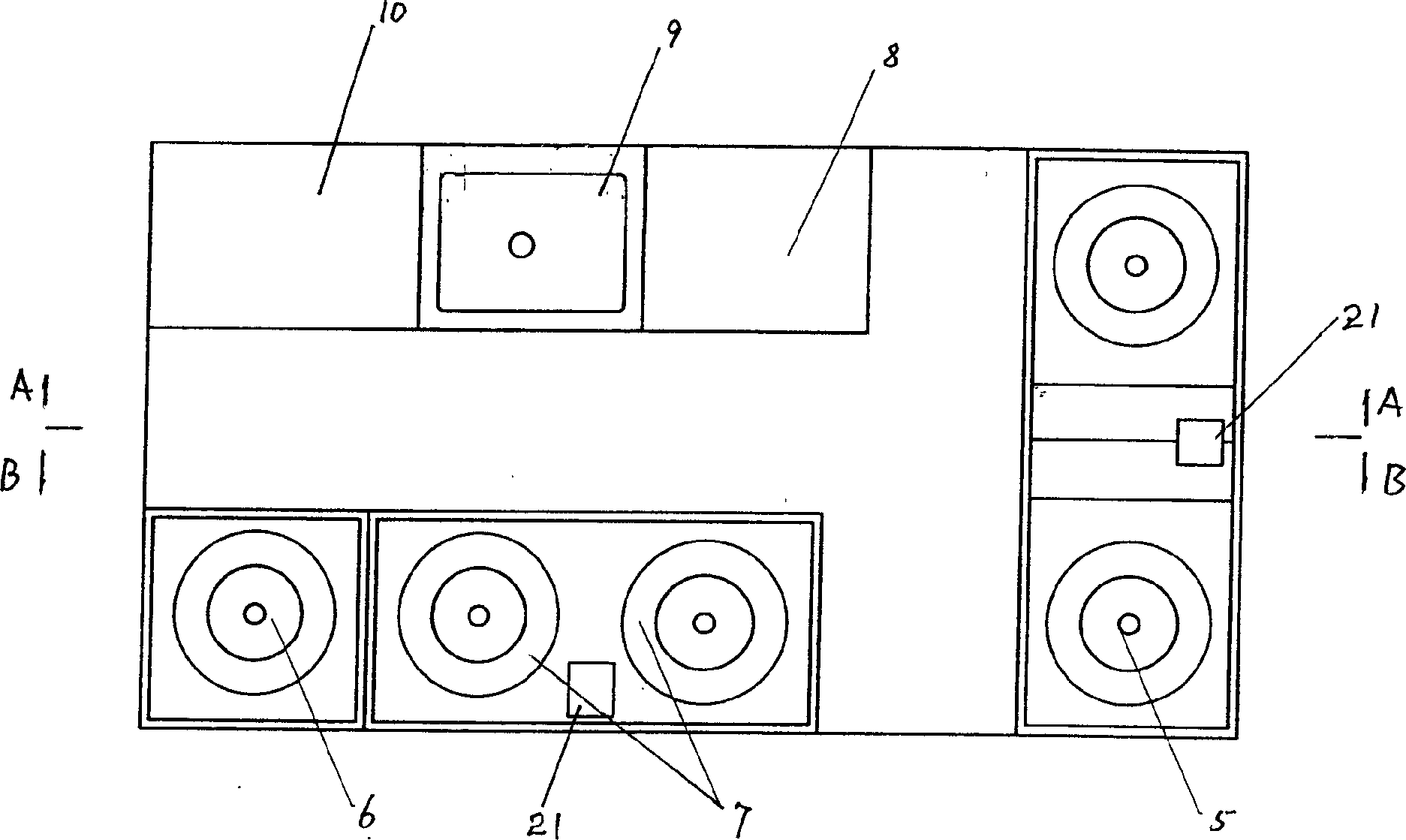

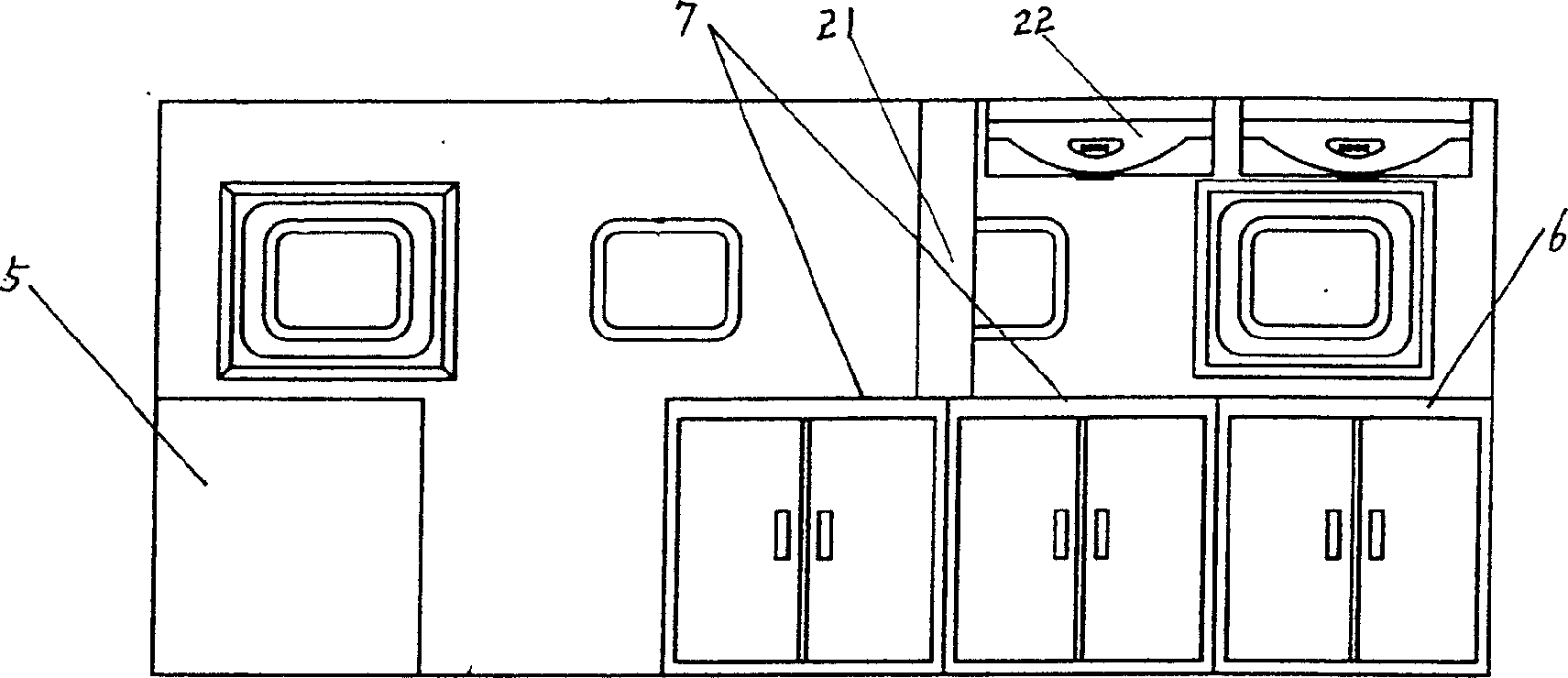

Cross-country self-propelled cooking vehicle

InactiveCN1676370AIncrease volumeImprove driving performanceWorkshop/display transportationCombustorDistribution system

The present invention relates to an off-road automative type kitchen truck, its chassis is off-road truck chassis, and on the platform a multifunctional cooking system and a multifunctional power distribution system are set. Said multifunctional cooking system is fixed on the inner wall of the vehicle body, and includes main food range, stir-frying range, stewing range, kneader, wasing tank, refrigerator and burner; and the multifunctional power distribution system includes shaft power generator, power-supply inverter, external power supply change-oven switching board, electric control main control box and electric control step control box, etc.

Owner:YUNNAN AEROSPACE IND

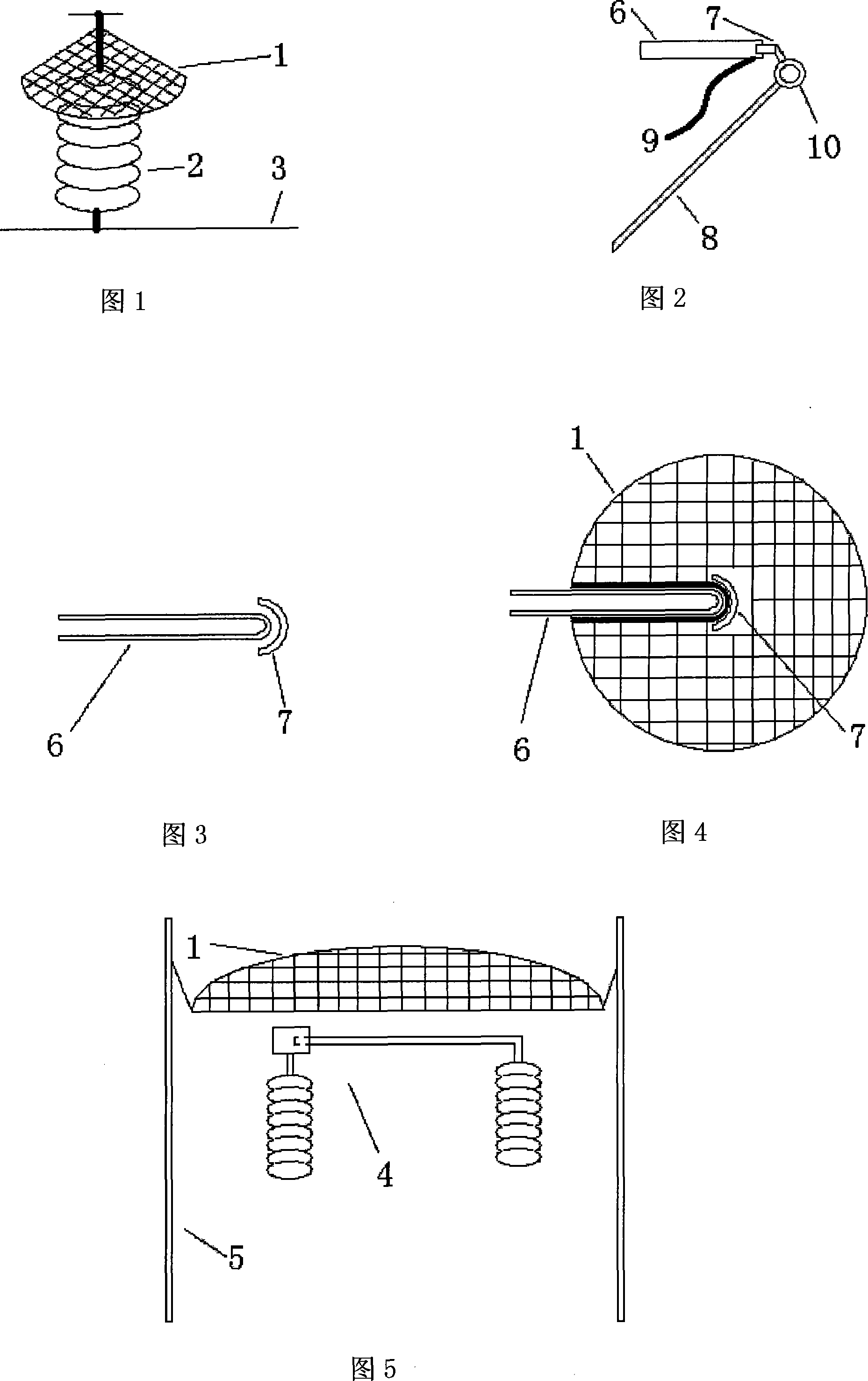

Ice-prevention mesh for open air power device

InactiveCN101237133APreserve electrical performanceReduce electrical accidentsOverhead installationNon-enclosed substationsWindageStorm

The invention relates to a protecting device for preventing outdoor power equipment from freezing; a net structure with toughness and proper rigidity under the low temperature is fixed on the top of the outdoor power equipment which needs freezing protection; the net structure is called an ice-preventing net. The principle of operation is that: if the net meets ice rain and snow, firstly the ice-preventing net freezes to form an ice cap which shades the outdoor power equipment positioning on the lower part free from freezing disaster. The design of the net structure is to reduce windage resistance and prevent gale damage. For mountainous areas with small wind power and rainy areas, the net structure is designed to a structure which is similar to a multiply eave with one layer pressing on another layer in order to increase certain anti-storm performance. The invention can preserve the electric appliance performance of the power equipment under the disastrous weather and reduces the power accidents caused by the reduction of equipment insulation. The invention can remarkably strengthen the safety of an outdoor power system.

Owner:天津有序环境科技发展有限公司

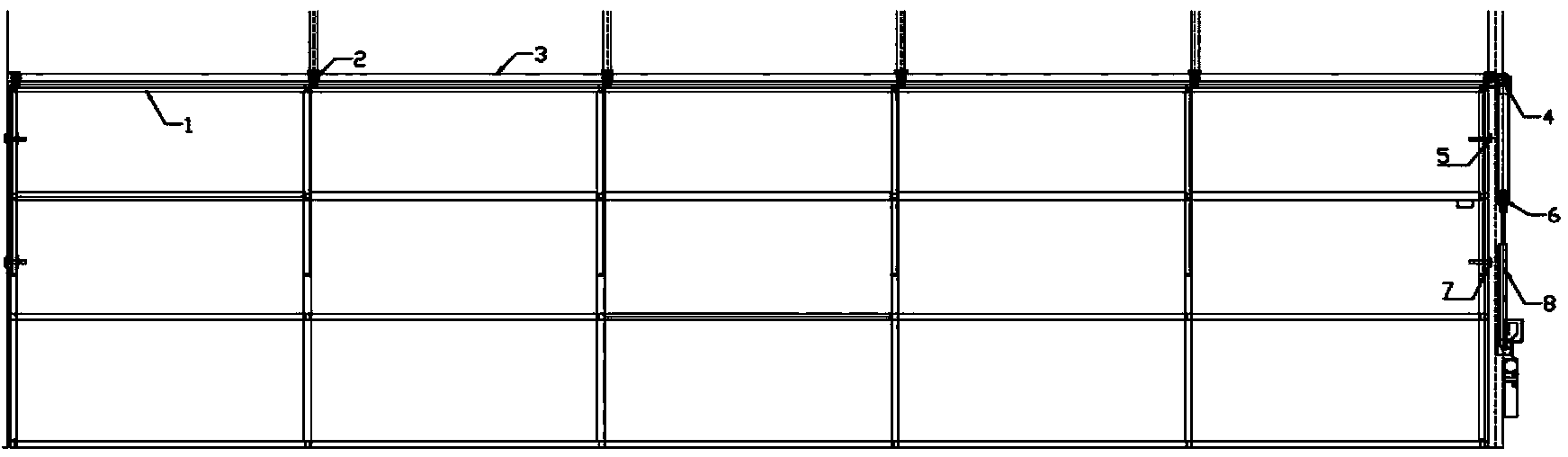

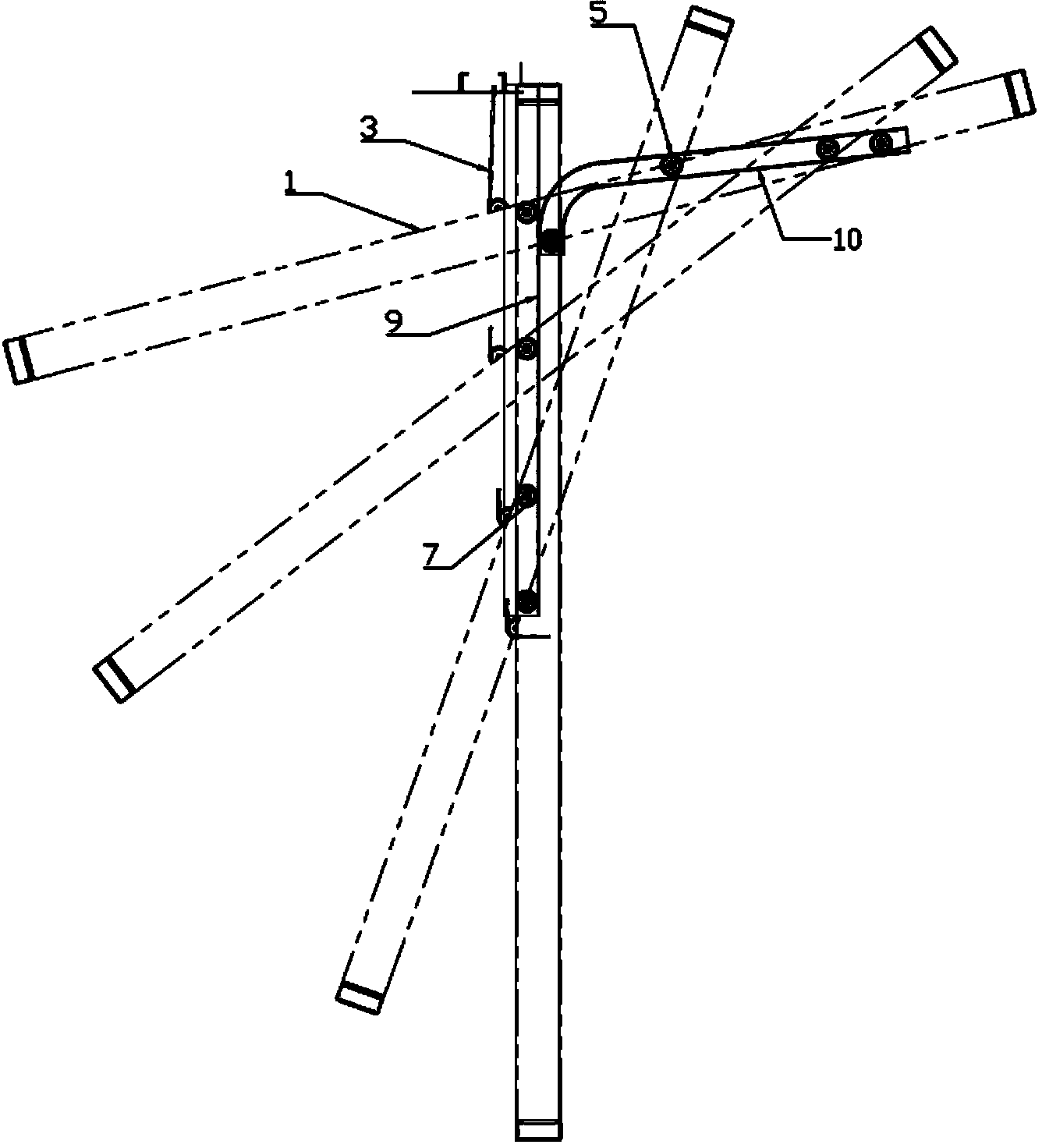

Giant whole floating hangar door

InactiveCN103437697AAvoid disadvantagesWith sound insulationGates/doorsPower-operated mechanismEngineeringPulley

The invention discloses a giant whole floating hangar door, and relates to a hangar door. The giant whole floating hangar door comprises a door main body, a first pulley, a wire rope, a second pulley, an upper wheel, a third pulley, a lower wheel, a telescopic cylinder, a vertical track and an inclined track, wherein the vertical track and the inclined track are arranged on the door main body; the lower wheel is arranged inside the vertical track; the upper wheel is arranged inside the inclined track; the wire rope is connected with the lower center part of an upright post of the door main body; the wire rope is connected with the telescopic cylinder through the first pulley, the second pulley and the third pulley orderly. By adopting the giant whole floating hangar door, the defects of a rolling door and a push-pull type hangar door are overcome; the giant whole floating hangar door has the advantages of low opening noise, sound insulation, heat insulation, heat preservation, wind resistance and fast opening and closing speed, and also has the advantages of being energy-saving, simple in structure and the like because of adoption of hydraulic power.

Owner:伟攀(上海)机械设备有限公司

Quick disassembling and assembling windproof enclosure

The invention discloses a quick disassembling and assembling windproof enclosure. The quick disassembling and assembling windproof enclosure comprises a frame. The quick disassembling and assembling windproof enclosure is characterized in that the frame is provided with a plurality of rotatable baffles through bearings, and the quick disassembling and assembling windproof enclosure further comprises a quick assembling frame, wherein the quick assembling frame is provided with a plurality of rotatable baffles through bearings, the quick assembling frame can be connected to one side of the frame, and a rotating mechanism capable of rotating the baffles on the frame and the baffles on the quick assembling frame connected with the frame is arranged on the frame. Wind force is induced through awind sensor, the baffles are rotated through the rotating mechanism, a second gear is locked by an electric push rod motor, the baffles rotate at a certain angle, gaps are formed between the baffles,the wind-bearing area of the enclosure is reduced, and the wind-resistant capability is achieved; the multiple enclosures can be quickly assembled through arranged convex blocks and rotating blocks,the rotating blocks can rotate at multiple angles, and an angle is locked by a bolt being inserted into an inserting hole, so that the functions of wind resistance, quick assembly and disassembly areachieved, the structure is simple, and the use is convenient.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

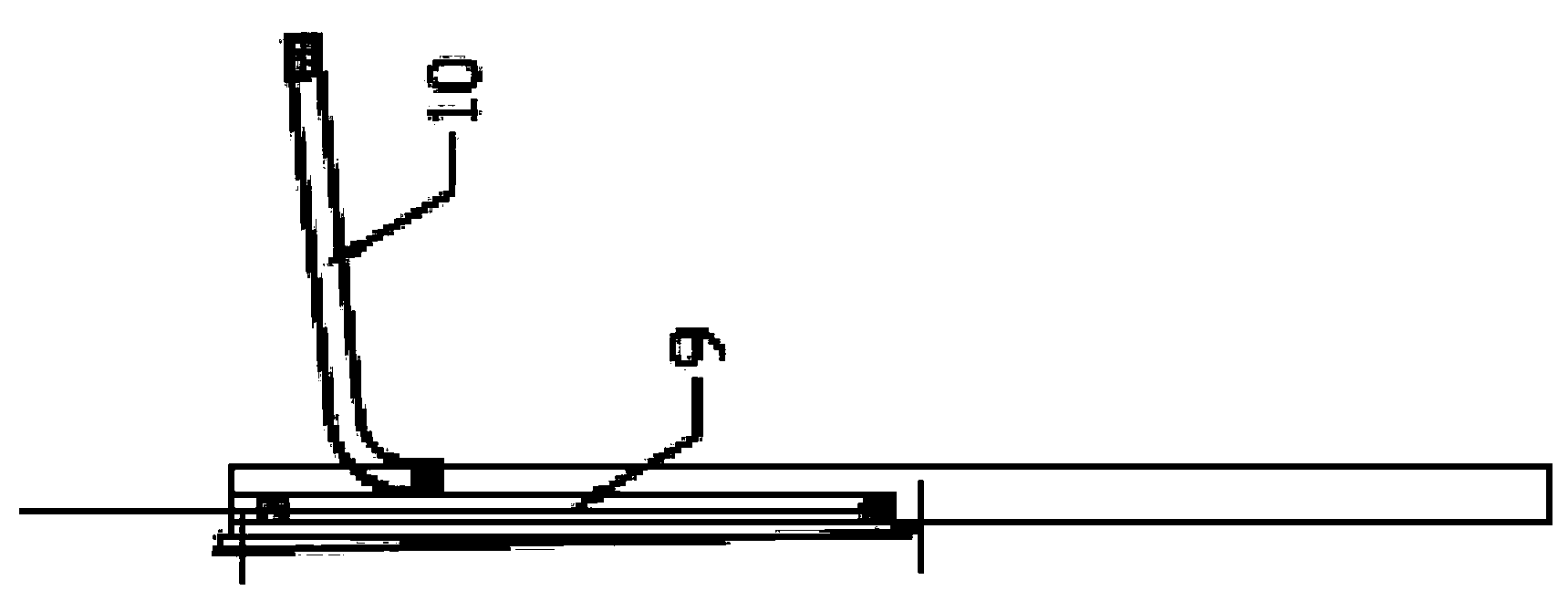

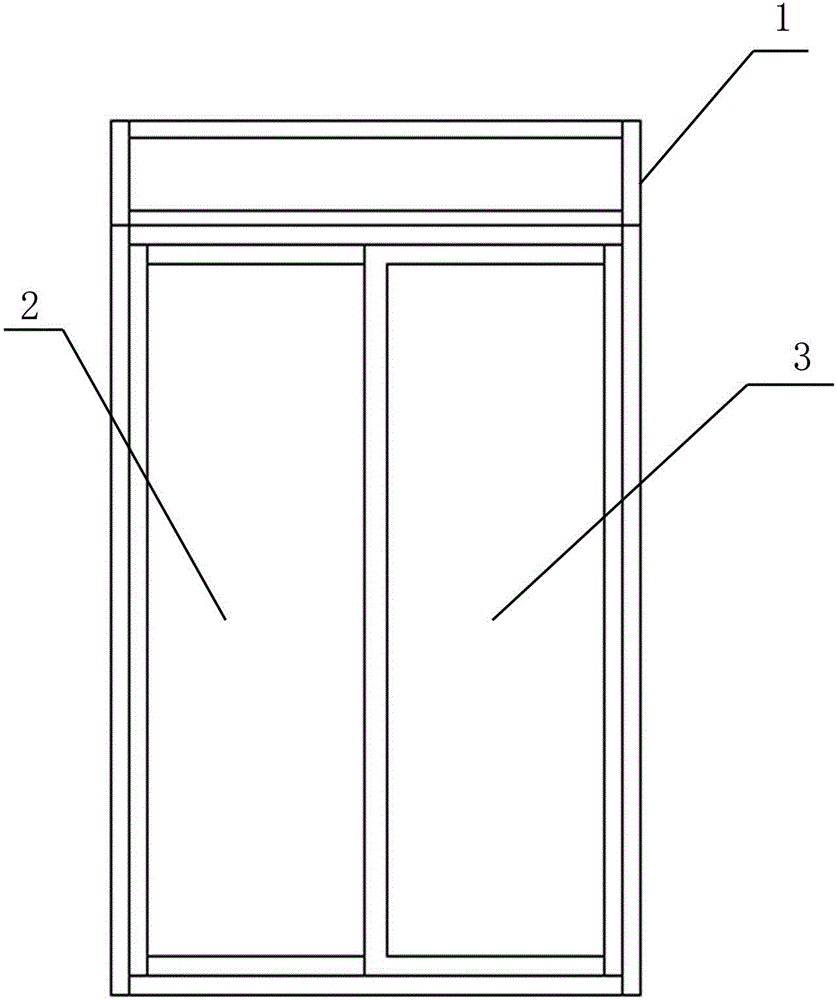

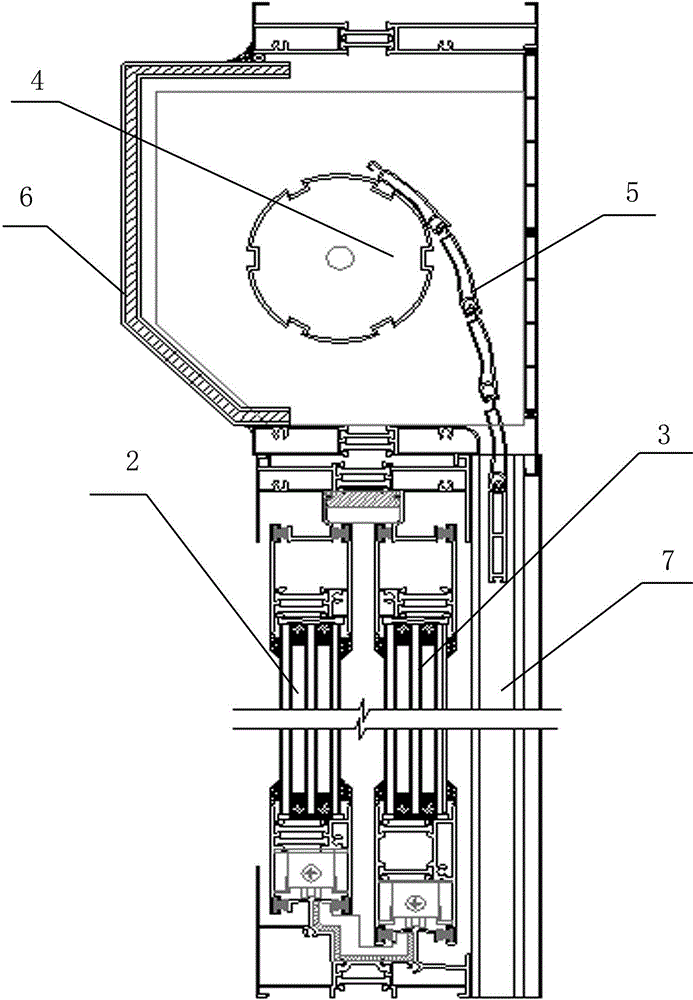

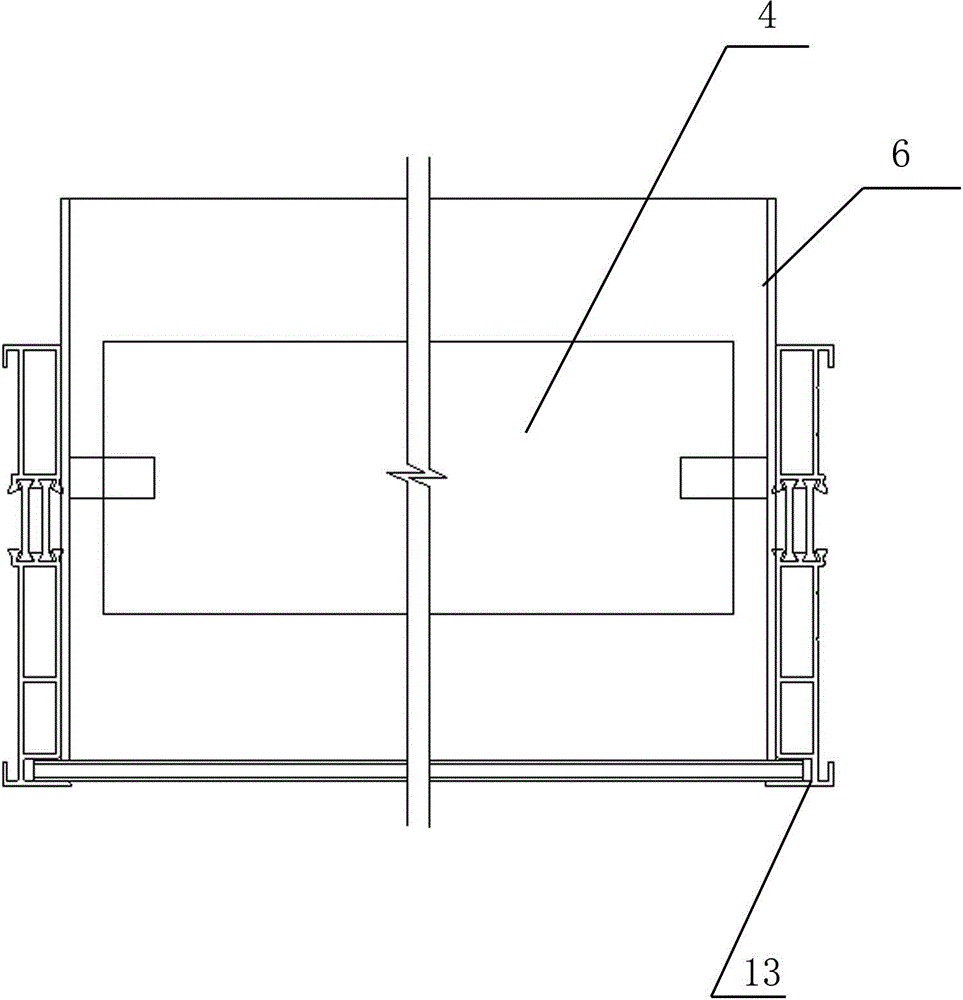

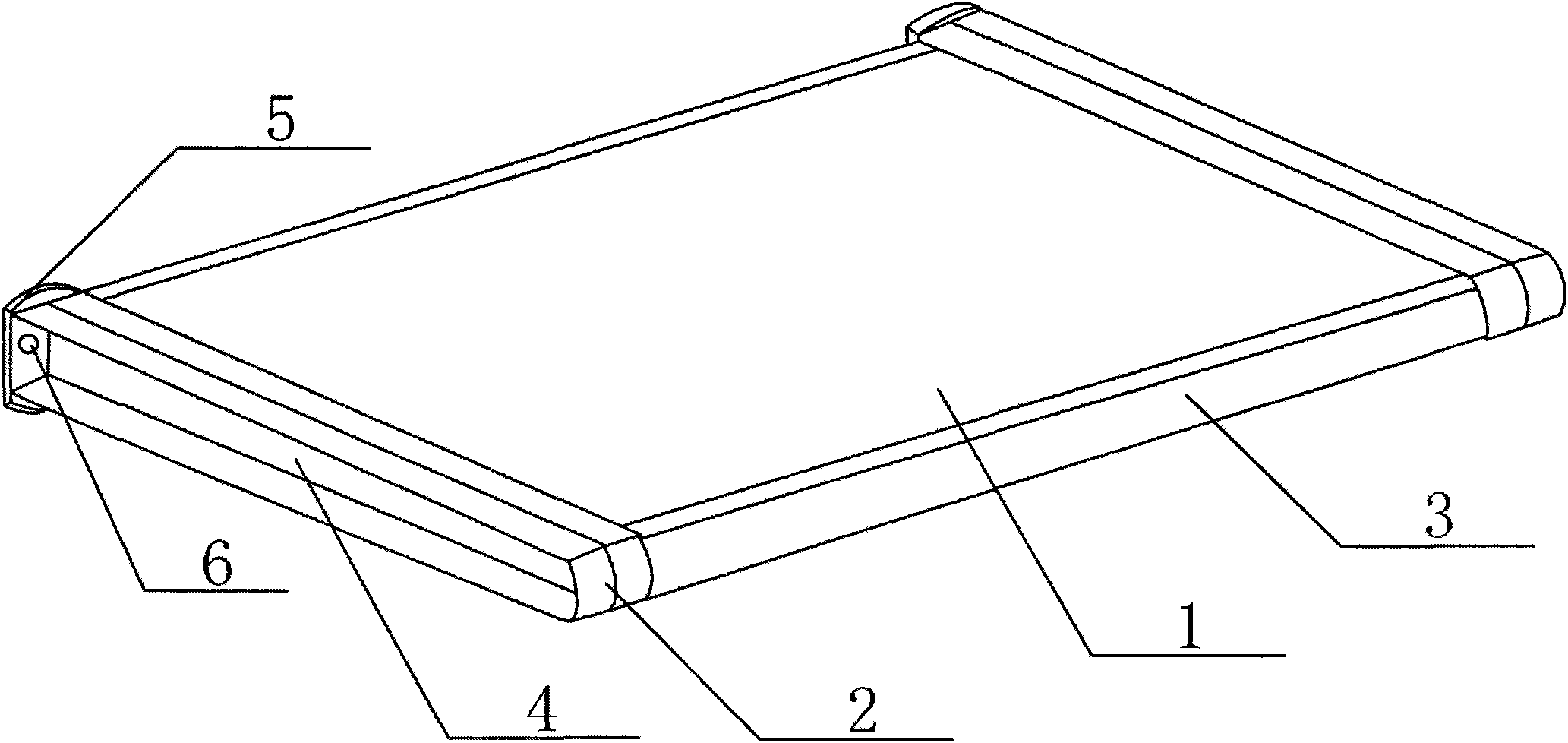

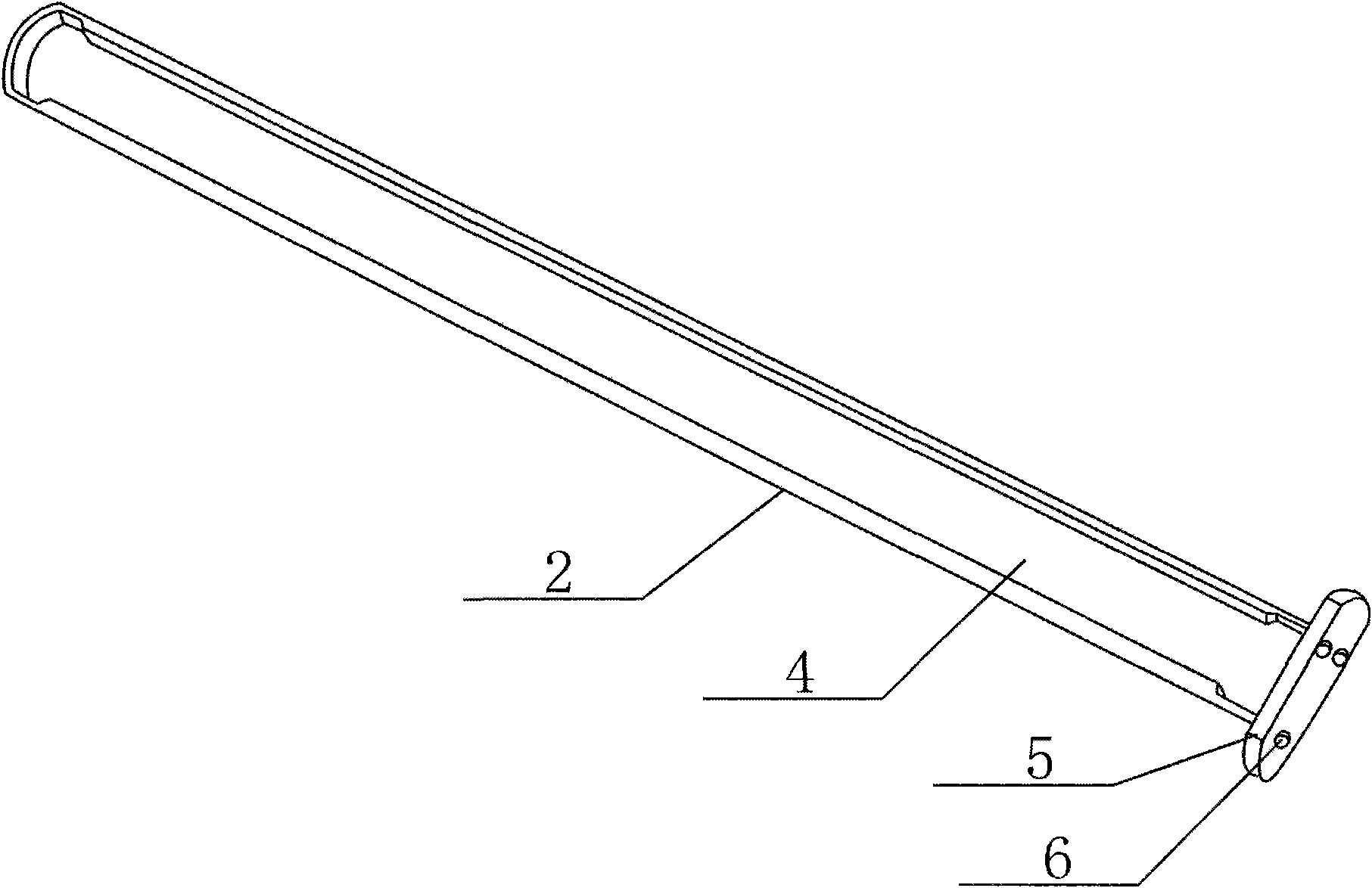

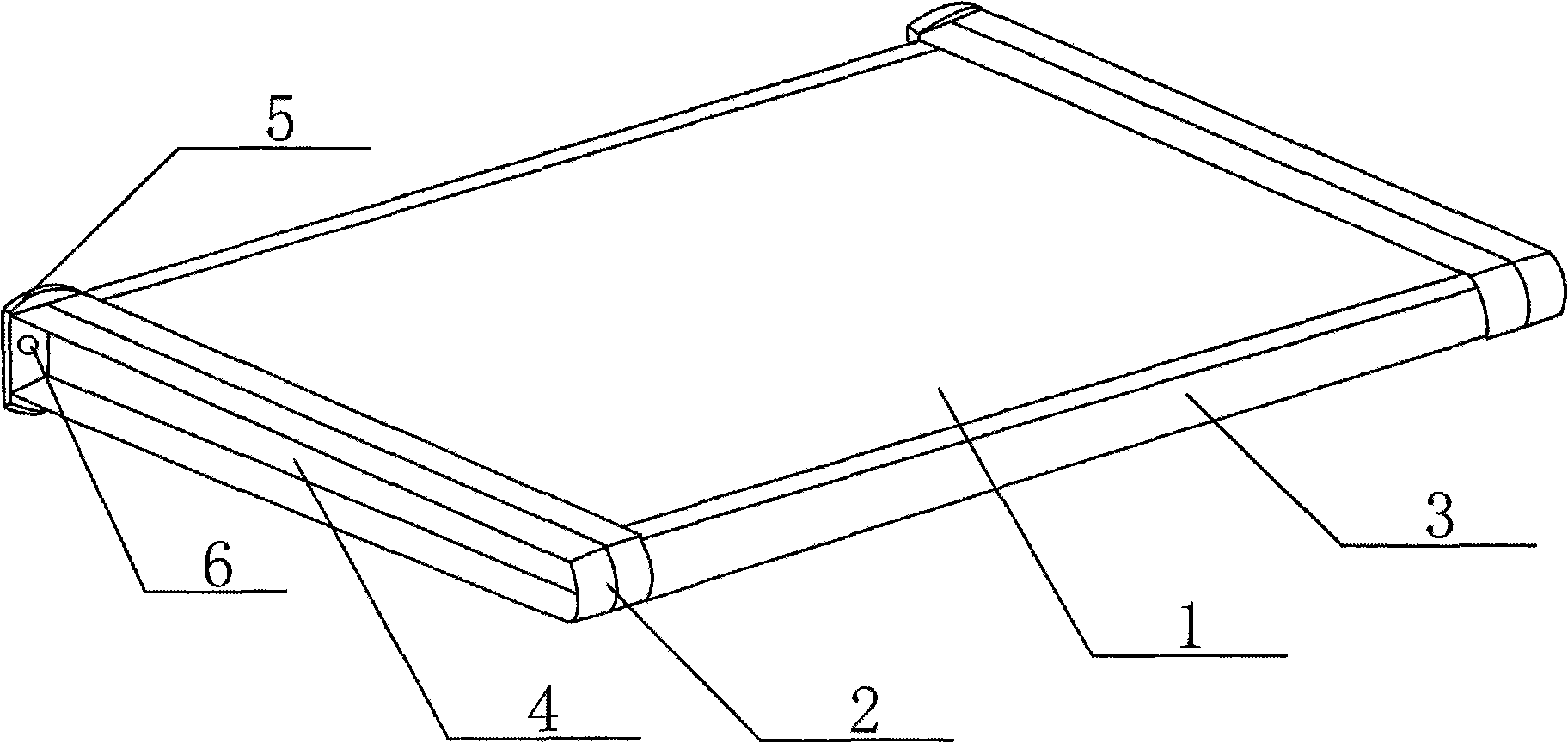

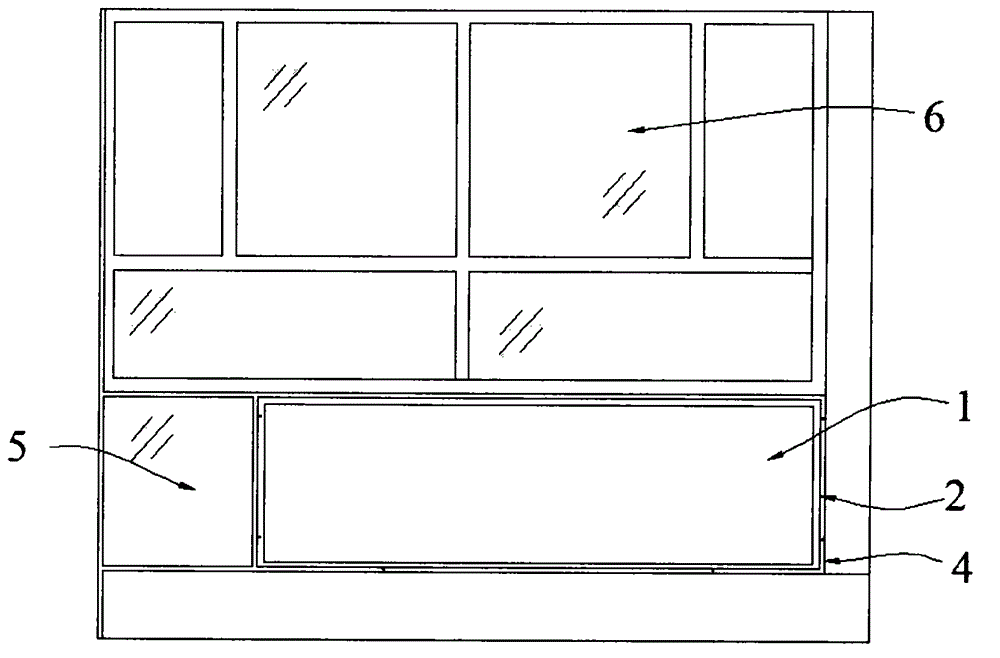

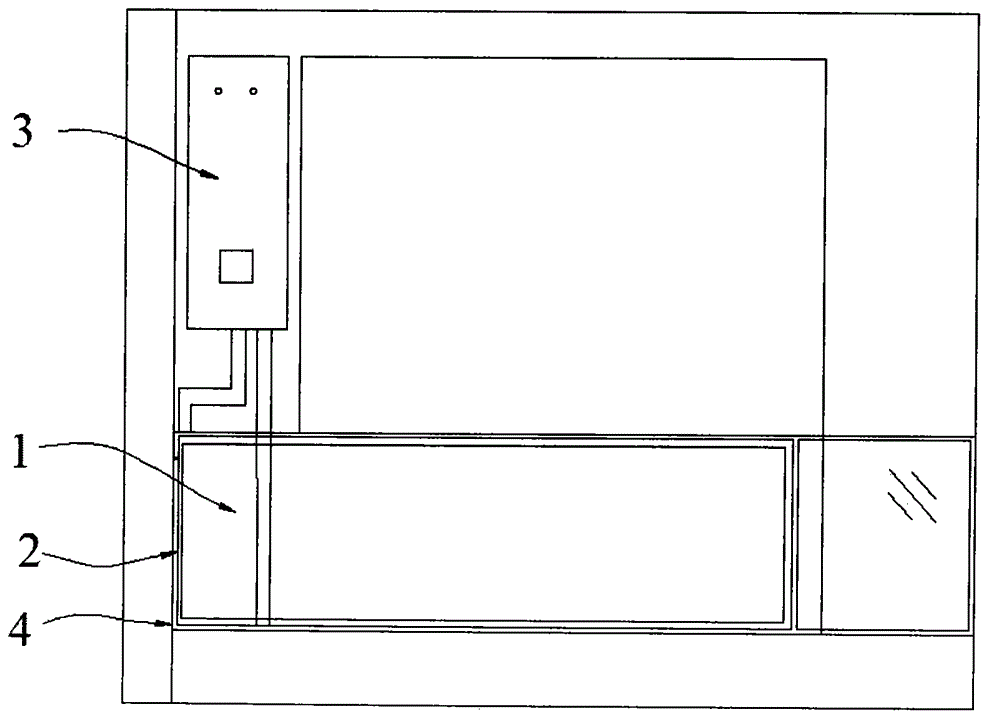

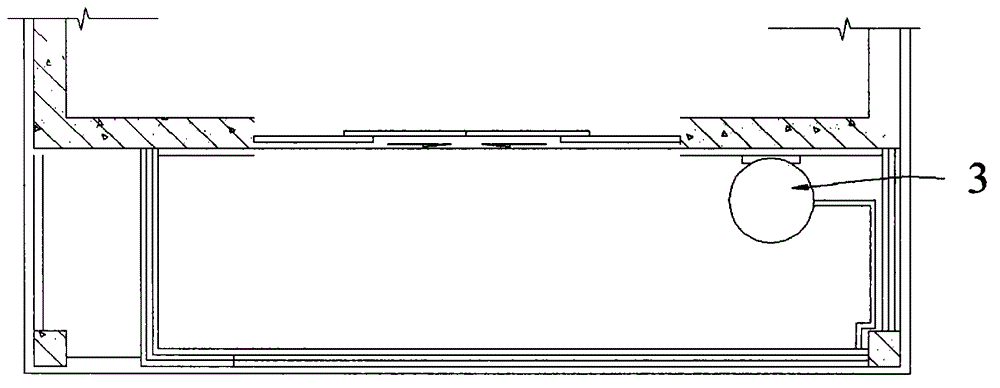

Integrated glass window with built-in metal roller blind

InactiveCN104563828ANo operational hazardLower installation feesShutters/ movable grillesPower-operated mechanismArchitectural engineeringMetal

The invention discloses an integrated glass window with a built-in metal roller blind. The integrated glass window comprises a metal roller blind window, wherein the metal roller blind window comprises a motor, a rotating shaft (4) and a metal sunshade curtain sheet (5); the motor and the rotating shaft (4) are positioned in a roller blind box (6) arranged on the top of a window frame (1) and are in transmission connection; the metal sunshade curtain sheet (5) is wound on the rotating shaft (4); a left curtain sheet guide slot (7) and a right curtain sheet guide slot (8) are respectively formed in the left side and the right side of the window frame (1) and are integrated with the window frame (1); the left side and the right side of the metal sunshade curtain sheet (5) are respectively positioned in the left curtain sheet guide slot (7) and the right curtain sheet guide slot (8); the motor drives the rotating shaft (4) to rotate; the rotating shaft (4) drives the metal sunshade curtain sheet (5) to be coiled or uncoiled; the two sides of the metal sunshade curtain sheet (5) move up and down in the left curtain sheet guide slot (7) and the right curtain sheet guide slot (8).

Owner:泰州市同裕节能门窗有限公司

Manufacturing process of wind-resistant advertising board

The invention discloses a manufacturing process of a wind-resistant advertising board, and relates to the technical field of advertising boards. The wind-resistant advertising board comprises a bottomplate, the upper surface of the bottom plate is fixedly connected with two supporting columns, the outer rings of the two supporting columns are fixedly connected with the inner wall of a hollow rhombic plate, and the front surface and the back surface of the hollow rhombic plate are each fixedly connected with two sliding rods. According to the manufacturing process, by arranging a second bearing and a second rotating shaft, on one hand, the advertising board is supported and fixed, on the other hand, the advertising board can rotate by a certain angle, then the advertising board can rotateunder the action of wind power when encountering strong wind; and then the wind can pass through a gap between the advertising board and a rectangular frame; therefore, the billboard is prevented fromgenerating large resistance to wind, the impact force of the wind to the billboard is reduced, the billboard is prevented from being damaged. As a result, the service life of the billboard is guaranteed, and therefore the billboard has certain wind resistance, and the safety under the strong wind load is guaranteed.

Owner:湖南秦汉标识有限公司

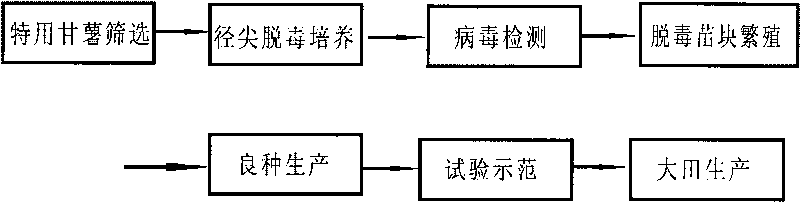

Method for raising seedlings of color virus-free sweet potatoes

InactiveCN101731143ADrought tolerantRidge resistantHorticulture methodsPlant tissue culturePharbitis nilShoot apex

The invention relates to a method for culturing and planting seedlings of color virus-free sweet potatoes. The method is characterized by utilizing the characteristic of low virus content or no virus content in stem tips of the sweet potatoes, cutting meristems of the stem tips of 0.2-0.4mm under an aseptic manipulation, forming test tube seedlings by culturing on a specific culture medium, and further detecting the virus-free seedlings by serology and indicator plant grafting. Meanwhile, the invention further provides the corresponding tissue rapid propagation technical regulations and a factorized production system according to different types, thereby accelerating the propagation of a large number of color style virus-free sweet potato seedlings. The method can propagate the potato species which has high nutritional value and bright color and is applicable to fresh-eating, baking or processing of the preserved sweet potatoes.

Owner:邱培标

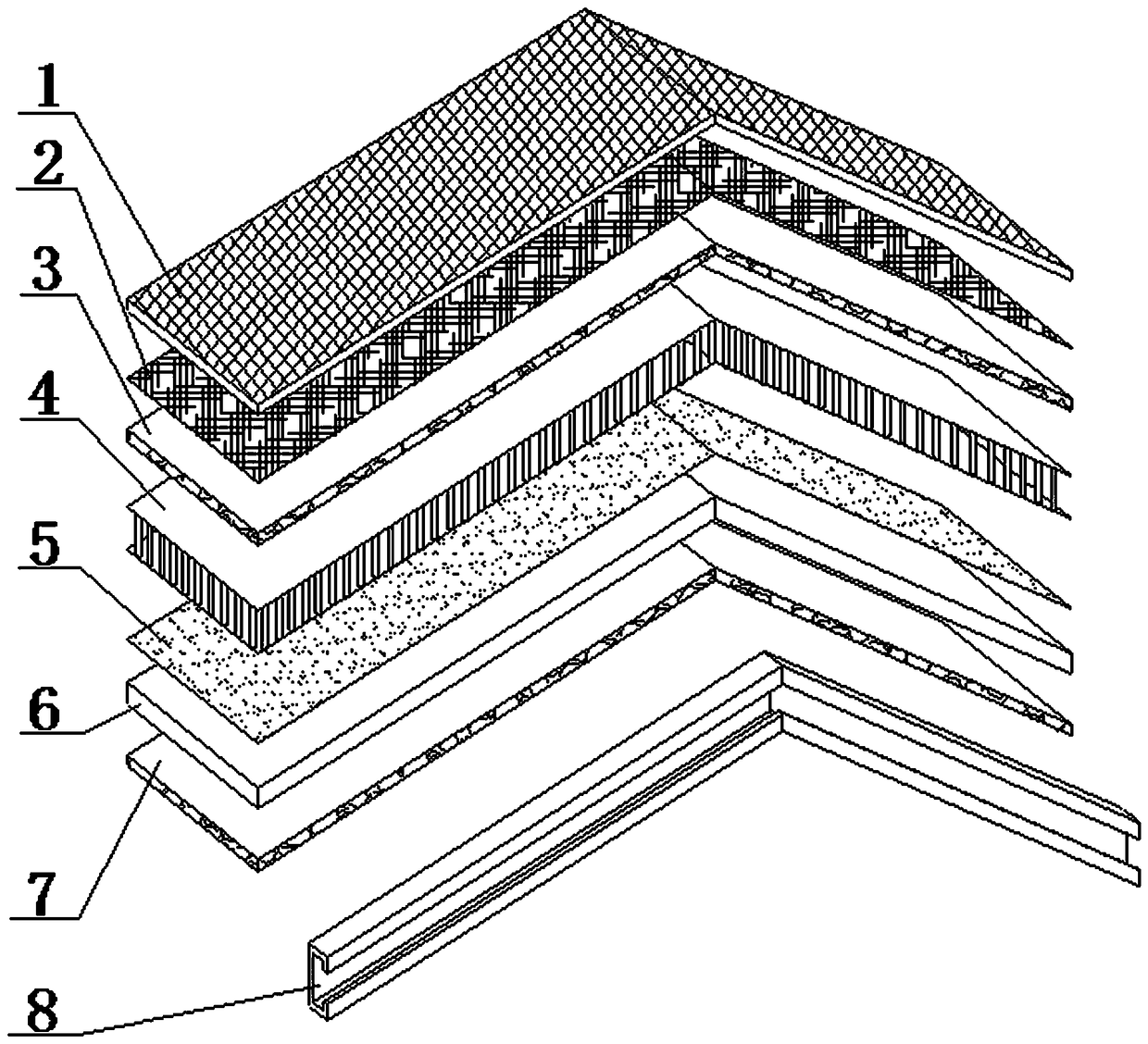

Roof of light steel structure house

PendingCN109339327AReasonable structureGood wind and shock resistanceBuilding roofsBuild-up roofsEarthquake resistanceThermal insulation

The invention discloses a roof of a light steel structure house. The roof from inside to outside is a light steel keel, roof OSB boards, an insulating layer, a ventilation layer, roof OSB boards, a waterproof layer and roof asphalt tiles. The light steel keel is filled with heat preservation and thermal insulation material, a wooden keel is placed in the middle of the ventilation layer, and breathing paper is pasted close to the insulating layer. The roof of the light steel structure house is reasonable in structure, light and solid, capable of achieving heat preservation and thermal insulation, capable of achieving sound insulation and flame resistance, capable of achieving water insulation and wind resistance, good in wind resistance and earthquake resistance effect and capable of withstanding certain pressure without deformation and displacement.

Owner:黎金莲

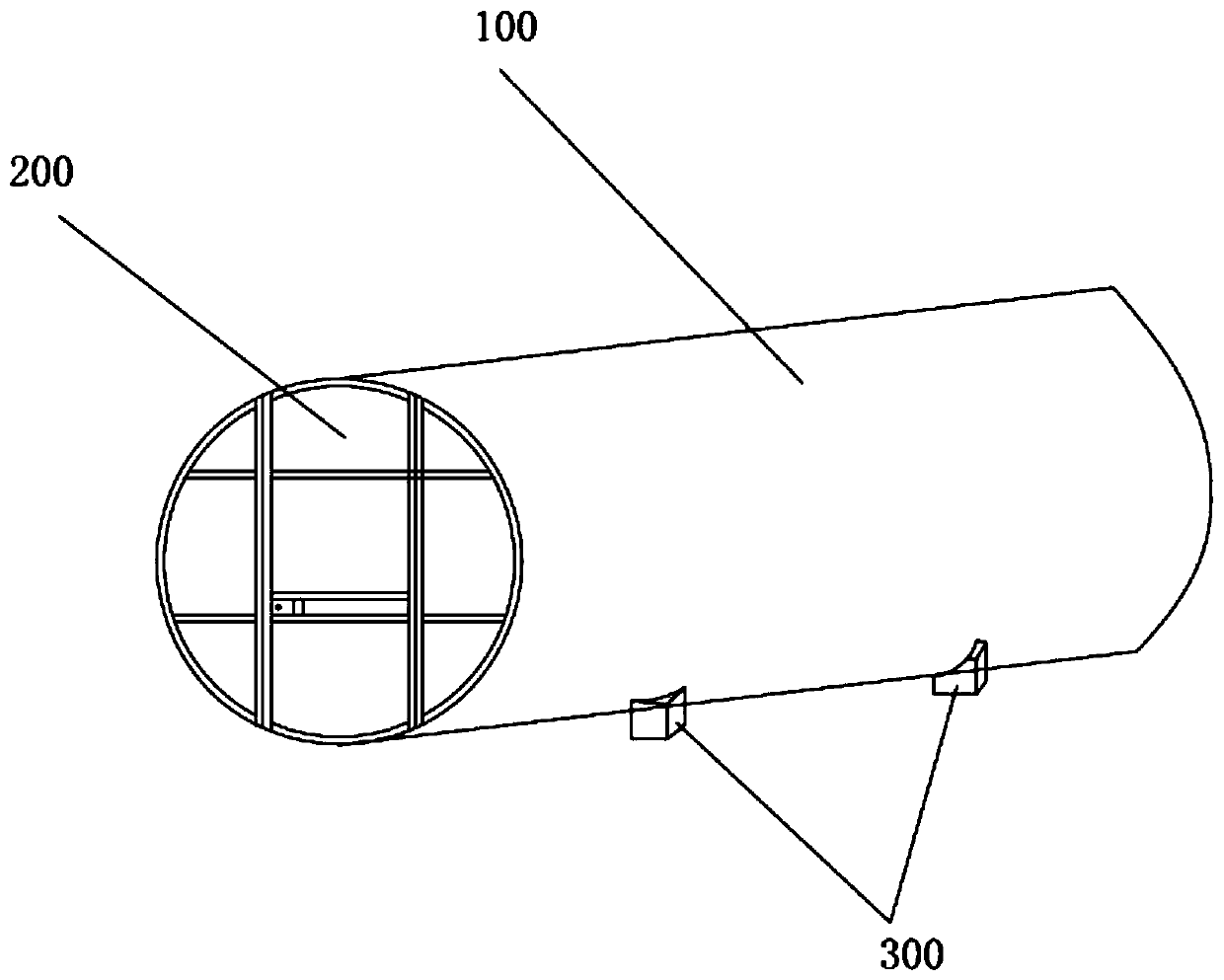

Fabricated ecological circular pipe house

PendingCN111270770AEasy to transportWind resistantExtraordinary structuresBuilding insulationsStructural engineeringComposite slab

The invention discloses a fabricated ecological circular pipe house and relates to the technical field of house construction. The technical problems that a cement pipe house in the prior art is hard to move and fails to be dismounted for reassembling are solved. The fabricated ecological circular pipe house provided by the invention comprises a circular pipe house body, a door and window mechanismand mounting bases, wherein the circular pipe house body is of a hollow cylinder structure formed by assembling a plurality of composite boards. The door and window mechanism is located on the end face of the circular pipe house body. The mounting bases are arranged on the lateral side of the circular pipe house body and used for fixing the circular pipe house body. According to the fabricated ecological circular pipe house provided by the invention, the circular pipe house body is formed by assembling the multiple composite boards and has the advantages of light weight, fast assembling and convenient transporting, and in general, one circular pipe house can be mounted by two persons within half a day; and since a fabricated structure is adopted, dismounting is convenient, and the application range of the house can be greatly expanded.

Owner:李相杰

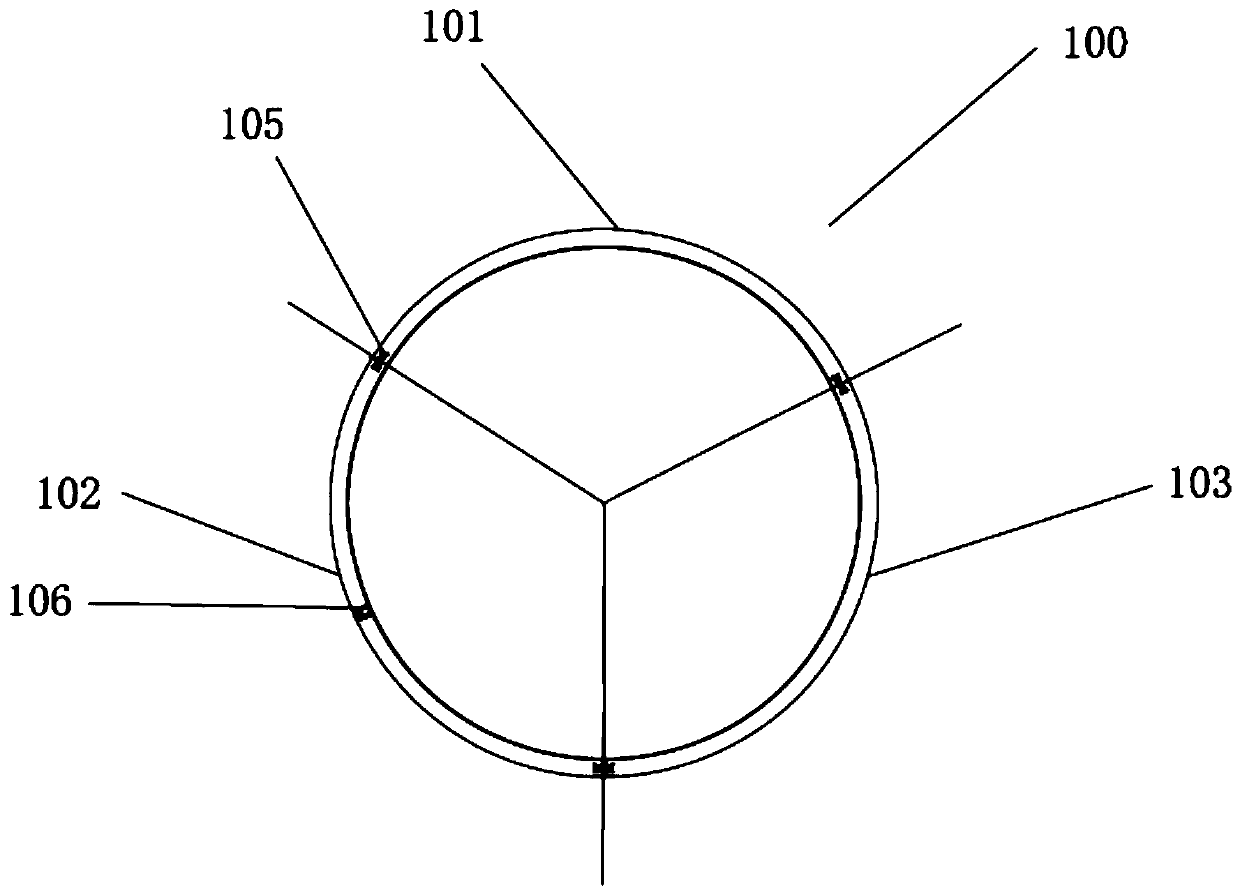

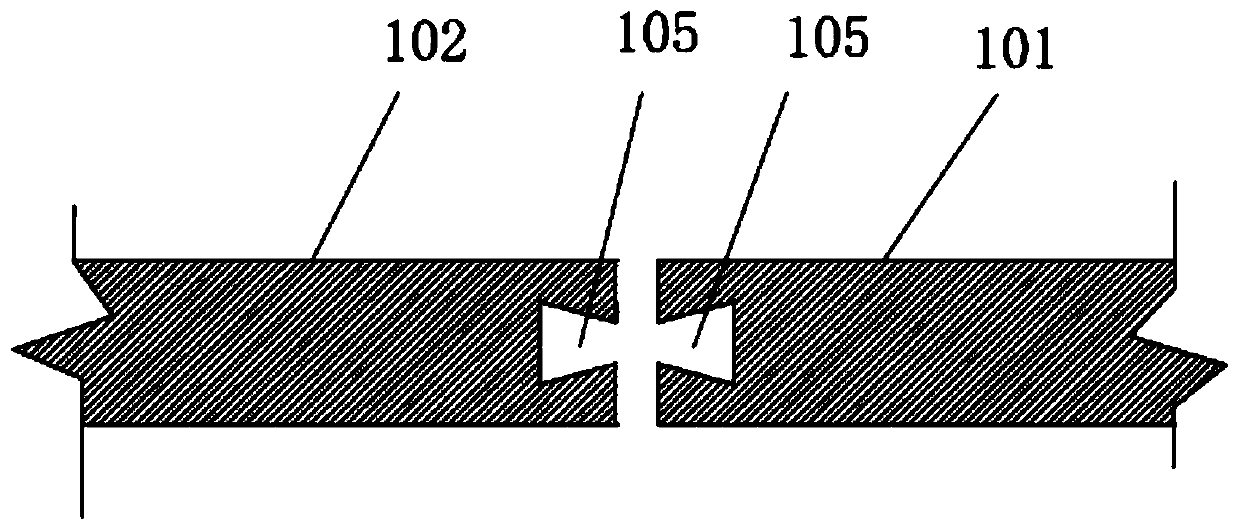

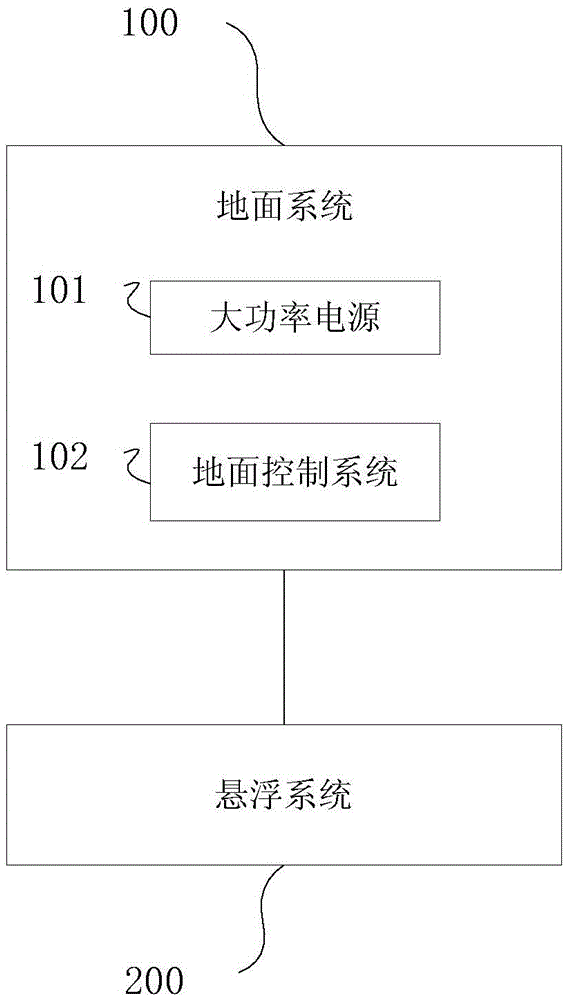

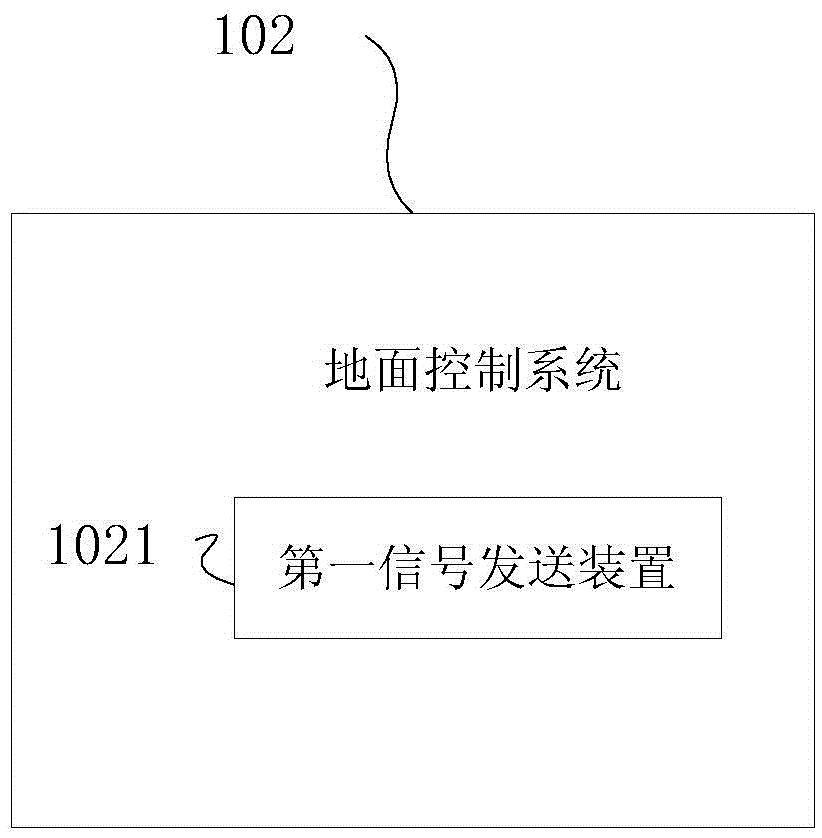

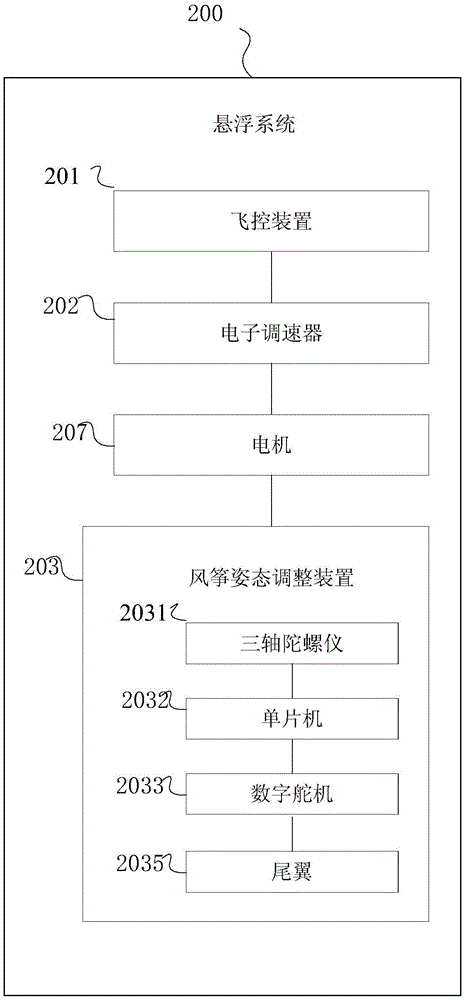

Kite suspension platform

The invention provides a kite suspension platform, and the platform comprises a ground system and a suspension system communicating with the ground system. The ground system comprises a large-power power supply which is connected with a 220V public network and used for supplying power to the suspension system. A ground control system is used for controlling the suspension system. The suspension system comprises a flight control device, an electronic speed regulator, a motor, and a kite posture adjustment device. The kite posture adjustment device comprises a three-axis gyroscope, a single-chip microcomputer, a digital steering engine, and a tail wing. Because a kite and an unmanned plane are combined at the same time, the formed kite suspension platform achieves the autonomous control of the posture, and overcomes a technical difficulty in balance control of the unmanned plane. The formed kite suspension platform is resistant to wind, is high in stability, is large in tension, and is economical.

Owner:BEIJING ELECTRIC POWER RES INST HUAYUANELECTRIC POWER TECH

Meridian-activating to stop pain tincture and preparation method of same

InactiveCN108096384APenetrate fastAvoid approachingHydroxy compound active ingredientsAntipyreticCentipedeLycopodium clavatum

The invention discloses meridian-activating to stop pain tincture and a preparation method of same. The medicine includes, by mass, 1-5 parts of angelica sinensis, 1-3 parts of flos carthami, 1-3 parts of red peony roots, 1-3 parts of dipsacus roots, 1-3 parts of radix clematidis, 1-3 parts of rhizoma drynariae, 1-5 parts of lycopodium clavatum, 1-5 parts of Chinese starjasmine stem, 1-3 parts ofradix aconiti preparata, 1-5 parts of caulis spatholobi stem, 1-3 parts of radix cyathulae, 1-3 parts of pericarpium citri reticulatae viride, 1-3 parts of peach kernels, 1-3 parts of divaricate saposhnikovia roots, 1-3 parts of notopterygium roots, 1-3 parts of radix angelicae pubescentis, 1-3 parts of agilawood, 1-3 parts of scorpions, 1-3 parts of centipedes, 1-3 parts of long-noded pit vipers,1-3 parts of camphor, 1-3 parts of menthol, 1-3 parts of wintergreen oil, and 50-100 parts of 60-degree baijiu. The medicine solves the problems that swelling-eliminating and pain-relieving medicinesin the prior art are low in medicine liquid content and poor in curative effects.

Owner:郑州思邈堂生物科技有限公司

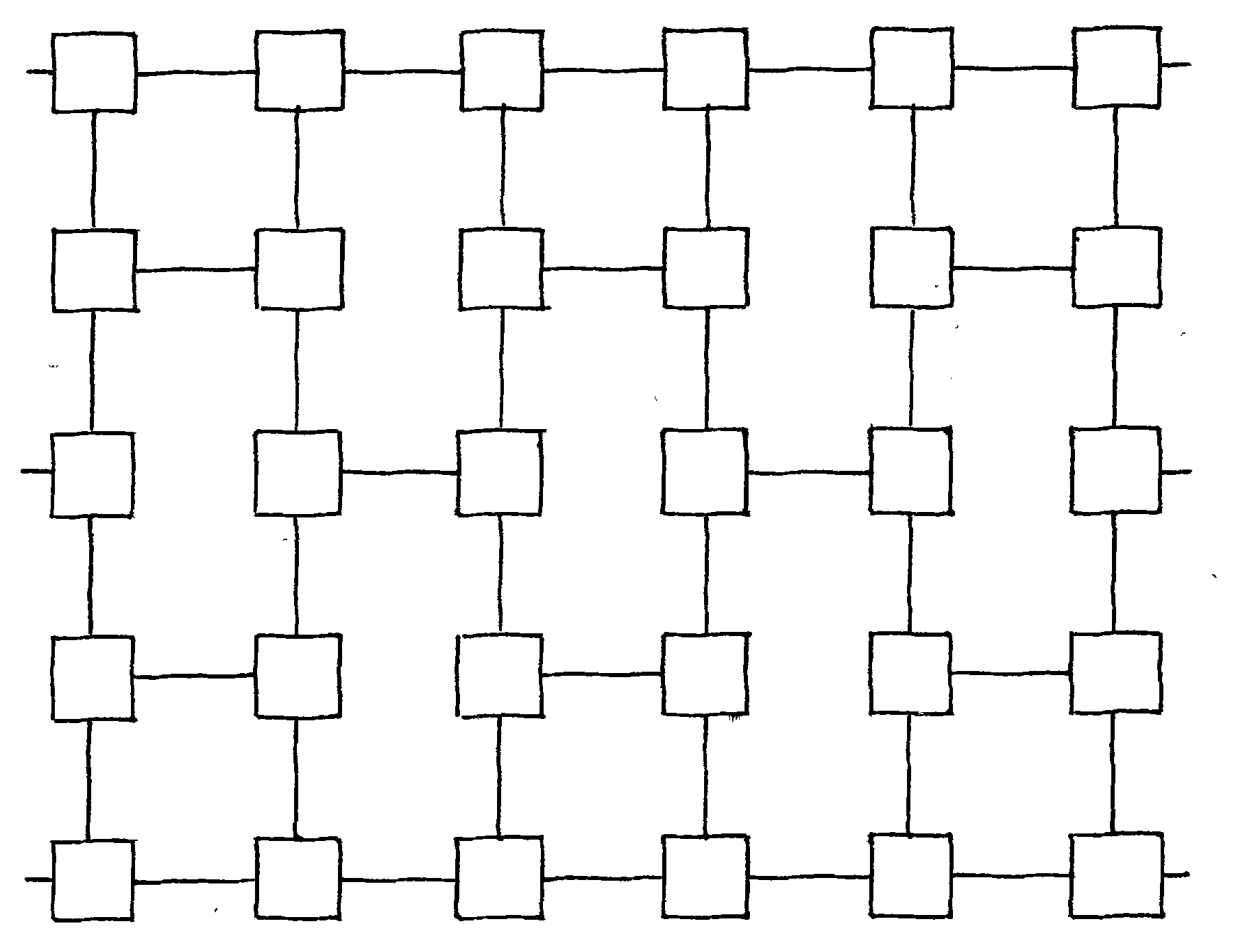

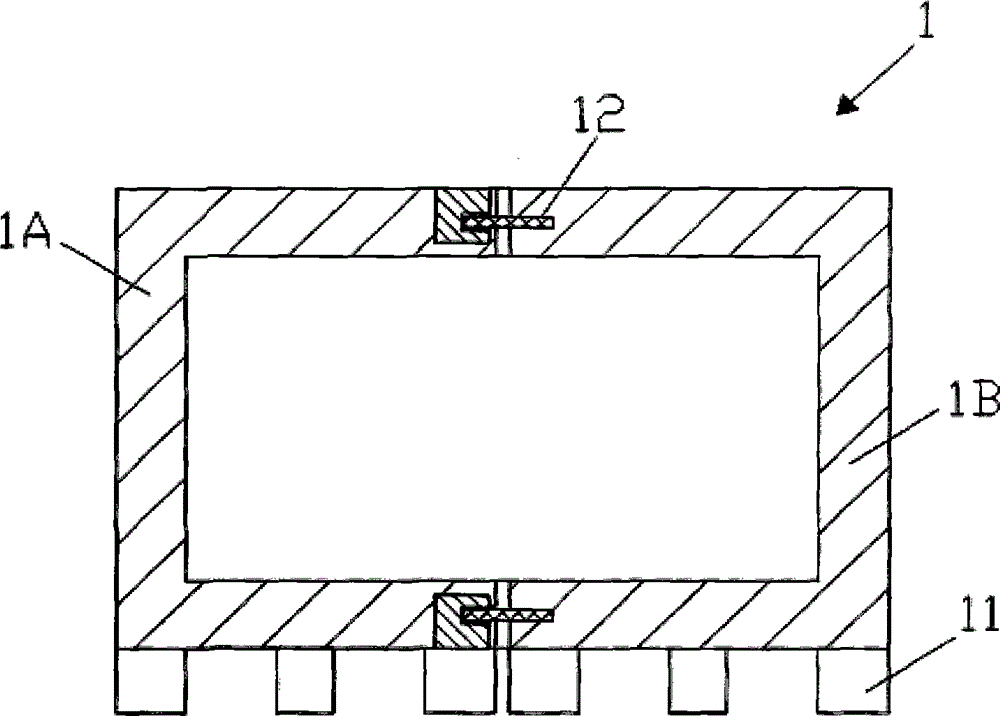

Hollow heat insulation wall and manufacturing method thereof

InactiveCN102839770AQuick buildMeet the indicator requirementsWallsCeramic shaping apparatusEarthquake resistanceHouse building

The invention provides a hollow heat insulation wall and a manufacturing method of the hollow heat insulation wall. The hollow heat insulation wall comprises a concrete inner wall and a concrete outer wall, a certain distance is reserved between the inner wall and the outer wall, and the inner wall and the outer wall are fixedly connected by metal trusses. The hollow heat insulation wall can be used for building up a building with good heat / sound insulation effect and the performance of concrete is verified for a long time by the existing buildings. The hollow heat insulation wall can be used for building up a multi-story building and can meet all technical index requirements of the building. The hollow heat insulation wall can be used as an assembly of a green and environment-friendly permanent building or a movable building and has the advantages of excellent earthquake resistance, fire prevention, water tightness, insect prevention, wind resistance, compression resistance, high strength and the like. The hollow heat insulation wall which is capable of overcoming the shortcomings of the existing building walls is a pressing need of the building industry at present.

Owner:谢秀英

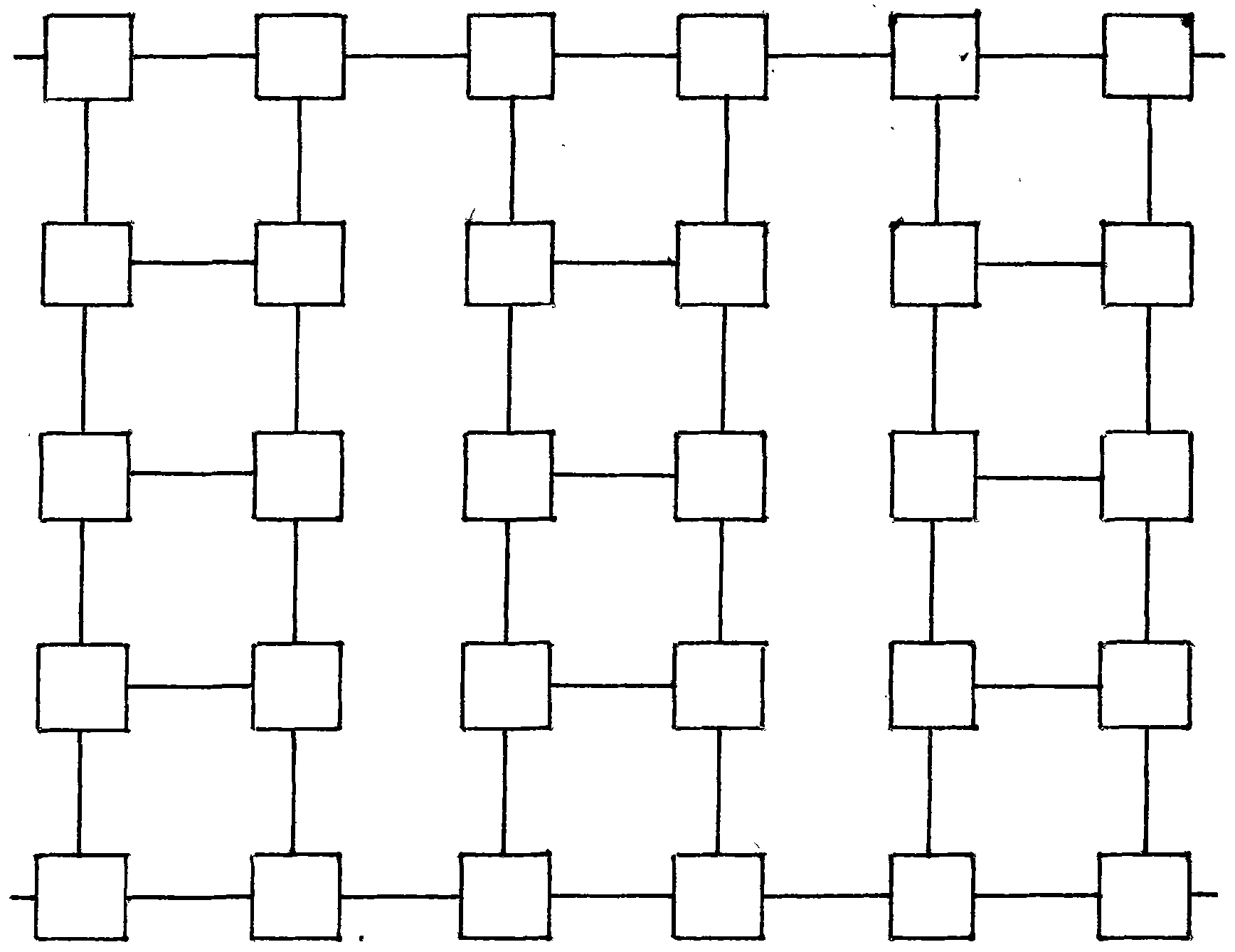

Tube check filed-type roof planting device

InactiveCN101861825ALow costReduce structural weightAgriculture gas emission reductionCultivating equipmentsStructural engineeringWater supply

The invention relates to a tube check filed-type roof planting device comprising a planting cup with three connecting holes lined in a T shape at the bottom and pipelines which are inserted into the connecting holes of the planting cup and are connected longitudinally and horizontally into a tube check field structure. The device has the advantages of smooth water supply, water-proofing, anti-wind, light weight, low cost and planting in large scale, and can be widely applied to the planting of vegetables, flowers and other small plants on a roof, so that the vacant roof has production benefits.

Owner:牛健

Construction method of Suzhou-embroidery-imitated technology wall

ActiveCN103161271AEasy to operateDoes not affect livingCovering/liningsLacquerStructural engineering

The invention relates to a construction method of a Suzhou-embroidery-imitated technology wall. The method comprises the following steps: (1) the surface of the wall is kept flat, and sealing treatment and priming treatment are simultaneously conducted; (2) positioning and drawing are conducted to make a pattern mould, and the pattern mould is assembled to a required position; (3) spraying and coating processes are conducted under the temperatures of 10-60DEG C; (4) when the wall body is not completely dried, a pattern plate is taken out to finish the whole wall surface bottom plate; (5) after the wall body bottom plate is completely dried, the plate is taken out, and wall body bottom plate colors are sprayed and coated; (6) flat lacquer or varnish is sprayed and coated after the colors are dried under the conditions that constant temperature of 20DEG C is kept and natural drying is conducted for 2 hours or so; (7) under the conditions that constant temperature of 20DEG C is kept and natural drying is conducted for 2 hours or so, and after finish coats are dried, gold-covering treatment of a pattern or coloring treatment of the pattern is conducted inside a model after finish coats are completely dried; and (8) finally, environment-friendly protective paint is painted, and manufacturing of the whole technology wall is finished. The construction method of the Suzhou-embroidery-imitated technology wall has the advantages of being simple in construction method, environment-friendly and free of taste in materials, anti-wind, anti-sunshine, anti-rain and applicable to all kinds of wall bodies.

Owner:李俊伟

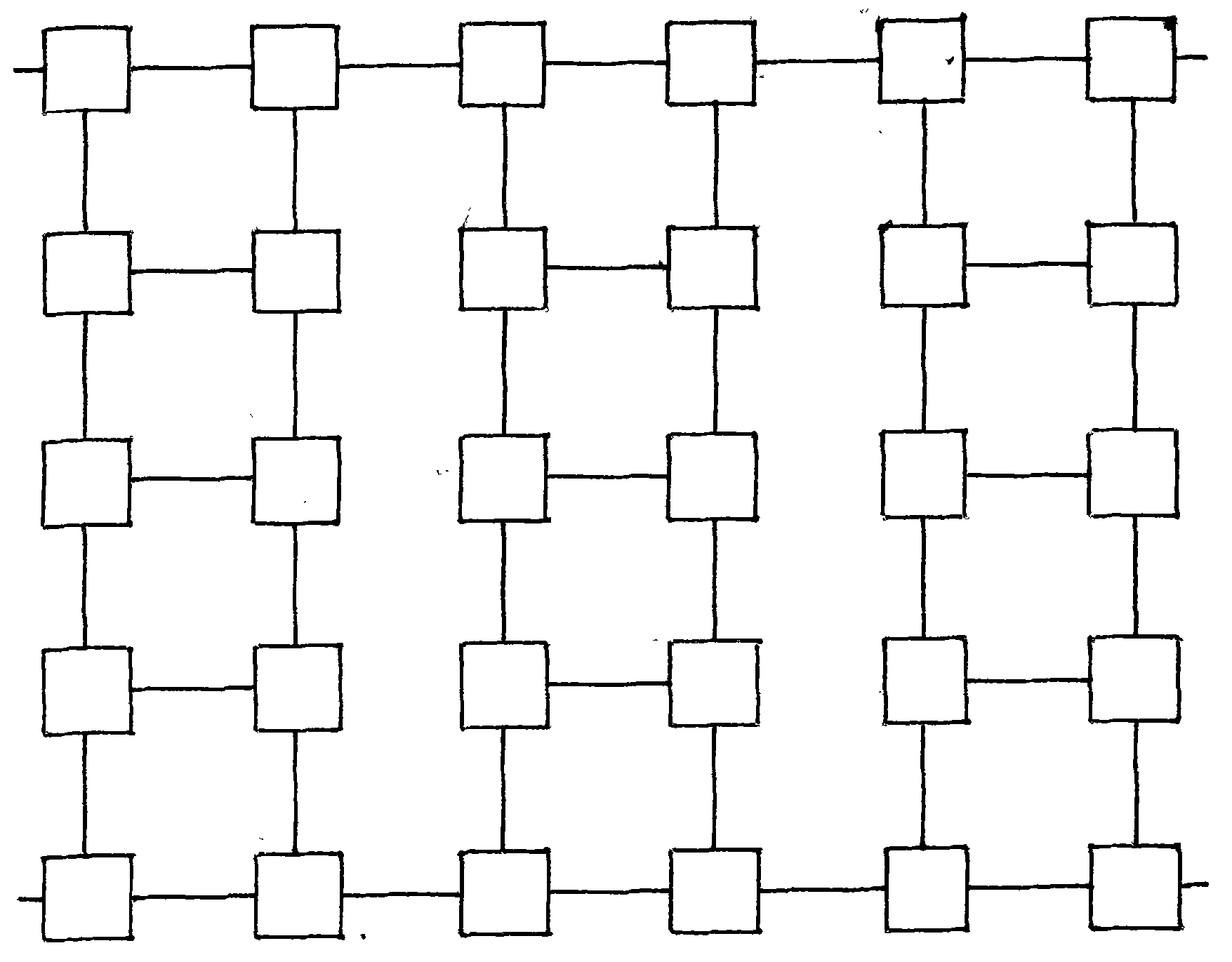

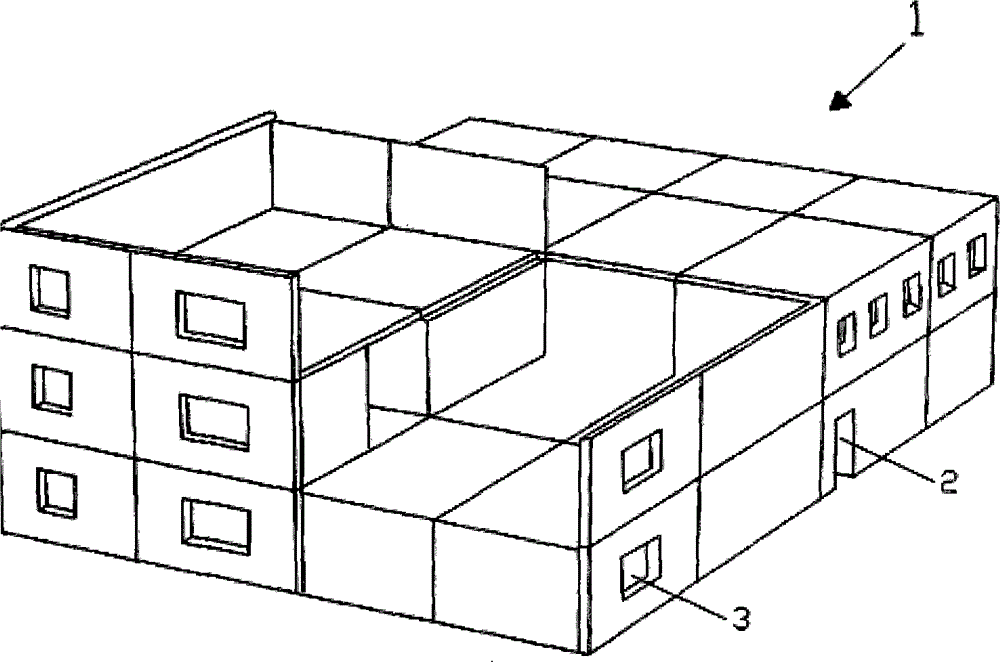

Container house and manufacturing method thereof

InactiveCN102828624BGood heat and sound insulationMeet the building index requirementsWallsClimate change adaptationContainerizationReinforced concrete

Owner:谢秀英

Construction method of Suzhou-embroidery-imitated technology wall

ActiveCN103161271BEasy to operateDoes not affect livingCovering/liningsLacquerStructural engineering

The invention relates to a construction method of a Suzhou-embroidery-imitated technology wall. The method comprises the following steps: (1) the surface of the wall is kept flat, and sealing treatment and priming treatment are simultaneously conducted; (2) positioning and drawing are conducted to make a pattern mould, and the pattern mould is assembled to a required position; (3) spraying and coating processes are conducted under the temperatures of 10-60DEG C; (4) when the wall body is not completely dried, a pattern plate is taken out to finish the whole wall surface bottom plate; (5) after the wall body bottom plate is completely dried, the plate is taken out, and wall body bottom plate colors are sprayed and coated; (6) flat lacquer or varnish is sprayed and coated after the colors are dried under the conditions that constant temperature of 20DEG C is kept and natural drying is conducted for 2 hours or so; (7) under the conditions that constant temperature of 20DEG C is kept and natural drying is conducted for 2 hours or so, and after finish coats are dried, gold-covering treatment of a pattern or coloring treatment of the pattern is conducted inside a model after finish coats are completely dried; and (8) finally, environment-friendly protective paint is painted, and manufacturing of the whole technology wall is finished. The construction method of the Suzhou-embroidery-imitated technology wall has the advantages of being simple in construction method, environment-friendly and free of taste in materials, anti-wind, anti-sunshine, anti-rain and applicable to all kinds of wall bodies.

Owner:李俊伟

Novel fixed-top awning

Owner:成都顶固科技有限公司

Assembly type concrete composite box beam and construction method thereof

ActiveCN106088470AImprove the bending capacityIncreased shear capacityLoad-supporting elementsReinforced concreteSteel frame

The invention discloses an assembly type concrete composite box beam and a construction method thereof. The assembly type concrete composite box beam is provided with a steel frame, a reinforced concrete beam reinforcement cage and concrete. The steel frame is divided into a left end steel frame portion, a middle steel frame portion and a right end steel frame portion in the extending direction of the assembly type concrete composite box beam. Both the left end steel frame portion and the right end steel frame portion are provided with support steel components and support additional flange steel components. The middle steel frame portion is provided with a lower supporting steel component, upper front side supporting angle iron, upper rear side supporting angle iron, a plurality of front beam side hoop plates and a plurality of rear beam side hoop plates. The left end steel frame portion, the middle steel frame portion and the right end steel frame portion are provided with a plurality of beam face hoop plates and a plurality of inner rib plates. The reinforced concrete beam reinforcement cage is arranged in the steel frame in a wrapped mode. The assembly type concrete composite box beam has the advantages of being simple in structure, convenient to manufacture and mount, capable of shortening the construction period and reducing steel consumption, economical, high in bearing capacity, good in stability, high in bending resistance and shearing resistance, high in rigidity and resistant to shock, wind, corrosion and fire.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Shock-absorbing and wind-absorbing steel structure prefabricated resettlement houses

InactiveCN110777941BAvoid shakingPrevent fallingProtective buildings/sheltersBuilding material handlingClassical mechanicsExternal cladding

A shock and wind reducing type steel structure fabricated temporary dwelling comprises a house, and the house is composed of a roof, multiple external wall mounting plates, a first neodymium-iron-boron magnet patch and multiple cross beams. Each external wall mounting plate comprises a vertical rod, a cross rod, a sun shield and a damping mechanism, and round holes are formed in the vertical rodsin the axial direction. Limiting blocks are fixed to the two sides of each vertical rod, and the cross rods are hinged to the two sides of the upper ends and the lower ends of the vertical rods. Mounting blocks and fixed plates are fixedly mounted on the cross rods. The first neodymium-iron-boron magnet patch can drive the external wall mounting plates to be mounted to be conveyed upwards, and a transmission system can be controlled by a controller. According to the shock and wind reducing type steel structure fabricated temporary dwelling, round design is overall adopted, and the shock and wind reducing type steel structure fabricated temporary dwelling is fashionable and attractive and has certain wind resisting performance. The house has certain earthquake resisting capacity, the housecan be prevented from collapsing as far as possible, and people in the house are prevented from being injured or dying as far as possible; and house external walls are mounted in a special manner, thehouse building period is short, and meanwhile the labor intensity of building worker is reduced.

Owner:融兴建设集团有限公司

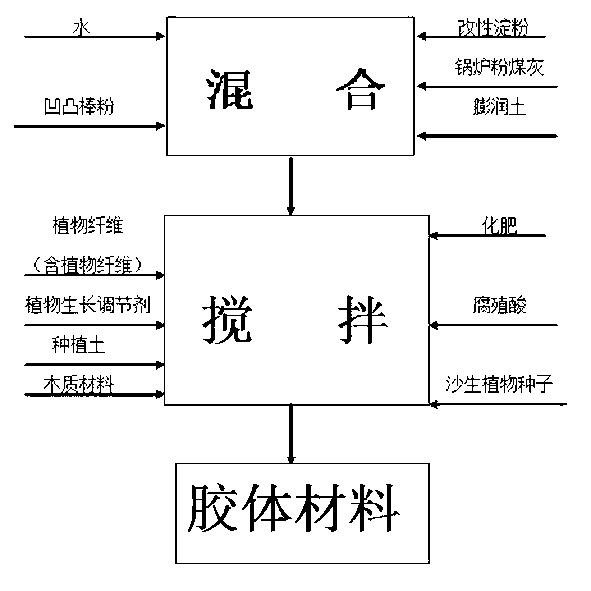

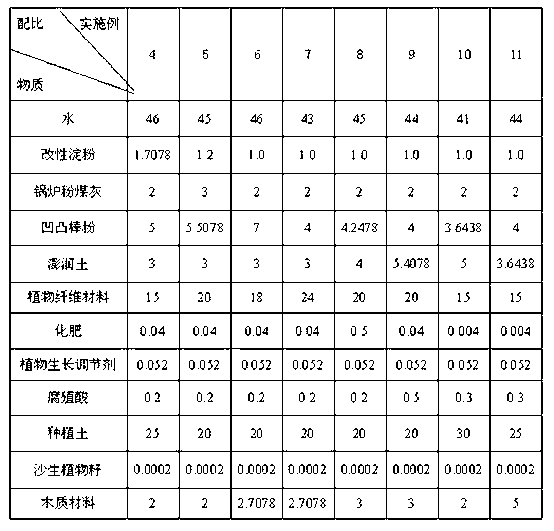

Gel material for desert planting and preparation method and using method thereof

InactiveCN102174329BImprove the growing environmentSuitable for growthOrganic fertilisersSoil conditioning compositionsFiberSodium Bentonite

The invention mainly relates to a material for desert greening control, a preparation method and a using method of the material. The invention particularly relates to a gel material for desert planting. The gel material consists of the following materials in percentage by weight: water, modified starch, boiler fly ash, attapulgite powder, bentonite, plant fiber material, fertilizer, plant growth regulator, humic acid, planting soil from farmlands and orchards, seeds of sand plants and wood material. The invention also provides a preparation method of the gel material for desert planting, which comprises two steps of: at normal temperature and pressure, mixing the water, the attapulgite powder, the boiler fly ash, the modified starch and the bentonite in a pot; and preparing mixed liquid. The invention also provides a using method of the gel material for desert planting, which comprises the following steps of: fixing wooden piles on the surfaces of desert sand beds; setting up antiskidnets on the wooden piles; and uniformly spraying the gel material on the antiskid nets by using a mud pump.

Owner:格尔木昆成农业科技开发有限公司

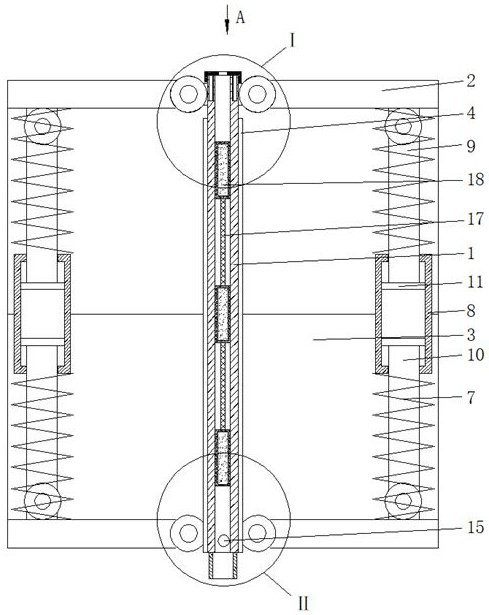

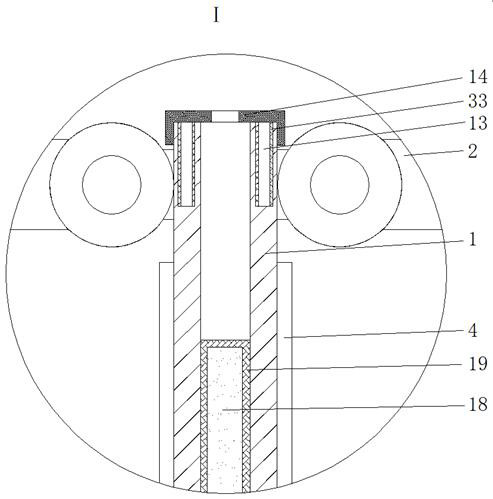

Long-distance high-precision elevation transfer aiming target plate

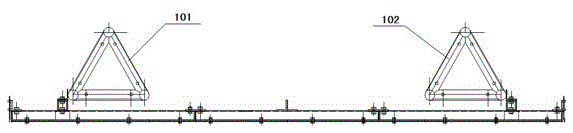

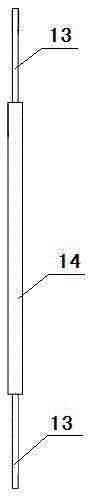

ActiveCN103487023BAccurate spacing adjustmentAccurate distance adjustmentHeight/levelling measurementAgricultural engineeringBlack light

The invention discloses a long-distance and high-precision height transmission alignment sighting board which comprises alignment components, adjustment rods and a support truss, wherein the alignment components are fixedly arranged on the support truss; the adjustment rods are arranged between the two alignment components; the alignment components comprise white lamp boxes and black light barriers; and every two black light barriers are fixedly arranged at the upper end of the lower end of each white lamp box respectively. The board can meet observation requirements in the day and at night, the stability of the alignment sighting board can be ensured, and the fabrication precision can meet alignment requirements of the corresponding grade.

Owner:长江三峡勘测研究院有限公司(武汉)

Unilateral hydraulically driven three-dimensional frame parking space

The invention provides a single-side hydraulic drive type stereoscopic frame parking stall and mainly solves problems that existing parking stalls occupy large areas and installation and operation are complicated. The single-side hydraulic drive type stereoscopic frame parking stall is characterized in that the cross section of a garage-shaped frame is in an h shape; traveling wheels are installed on lower portions of side edges and travel on the ground track; a lifting slewing device installed on a stand column frame comprises a slewing stand column, an upper slewing support and a lower slewing support, the slewing stand column is installed between the upper slewing support and the lower slewing support, the upper slewing support and the lower slewing support are fixed on an upper cross beam and a lower cross beam of the stand column frame respectively, and a hydraulic slewing driving device which drives the slewing stand column to slew is installed on one slewing support; and a lifting sliding sleeve driven by a hydraulic cylinder is sleeved on the slewing stand column, and a vehicle carrying table board is fixed at the lower end of the lifting sliding sleeve. The single-side hydraulic drive type stereoscopic frame parking stall has the advantages that by means of a frame type main body and single-side hydraulic drive, the stereoscopic frame parking stall is simple in structure.

Owner:阜新工大科技发展有限公司

Sealed window integral type flat plate solar water heater and installation method thereof

ActiveCN104390376AWith heat collection functionThe heat collection function meets theSolar heating energySolar heat devicesThermal insulationSolar water

The invention discloses a sealed window integral type flat plate solar water heater and an installation method thereof. The sealed window integral type flat plate solar water heater comprises a flat plate solar heat collector, a mounting frame and a pressure water tank, wherein the flat plate solar heat collector is arranged on a window frame of a sealed window through the mounting frame, and is connected with the pressure water tank. The sealed window integral type flat plate solar water heater has the advantages that the structure design is reasonable; the flat plate solar heat collector is skillfully embedded in the window frame of the sealed window to form an integral structure, so one part of area of a window is saved, the installation of a fence is not needed, the requirement of building safety specifications is met, the repeated investment is avoided, and the cost is reduced; the special equipment or tools are not needed for installation, the installation is quick and firm, the detachment is convenient, the heat collection, heat isolation, heat insulation, water-proof and wind-resistant functions are realized, the appearance is attractive, the trend of Chinese energy-saving and emission-reduction policies is met, and the sealed window integral type flat plate solar water heater is favorable for being widely popularized and applied. The installation method has the advantages that the step is simple, the implementation is easy, the installation is convenient, the assembly is firm, and the safety is high.

Owner:怀来清华华丰太阳能有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com