Assembly type concrete composite box beam and construction method thereof

A technology for reinforced concrete beams and concrete, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problems of large transportation and installation workload, large construction workload, and self-heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

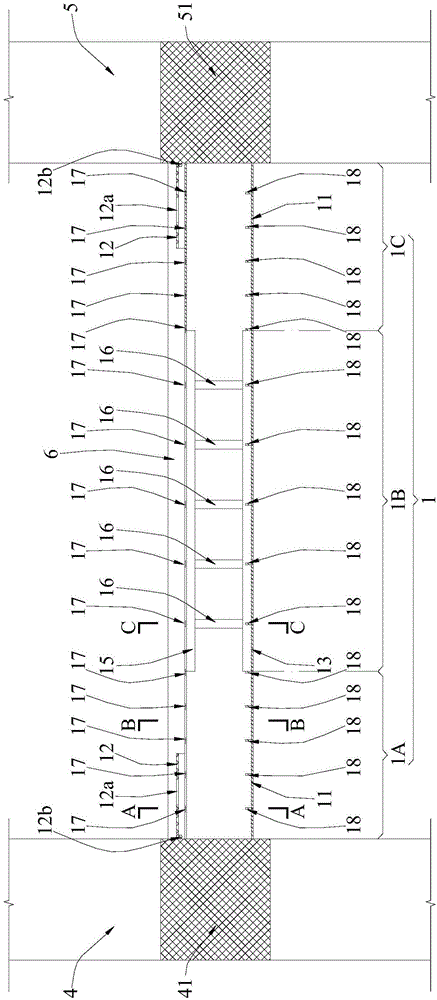

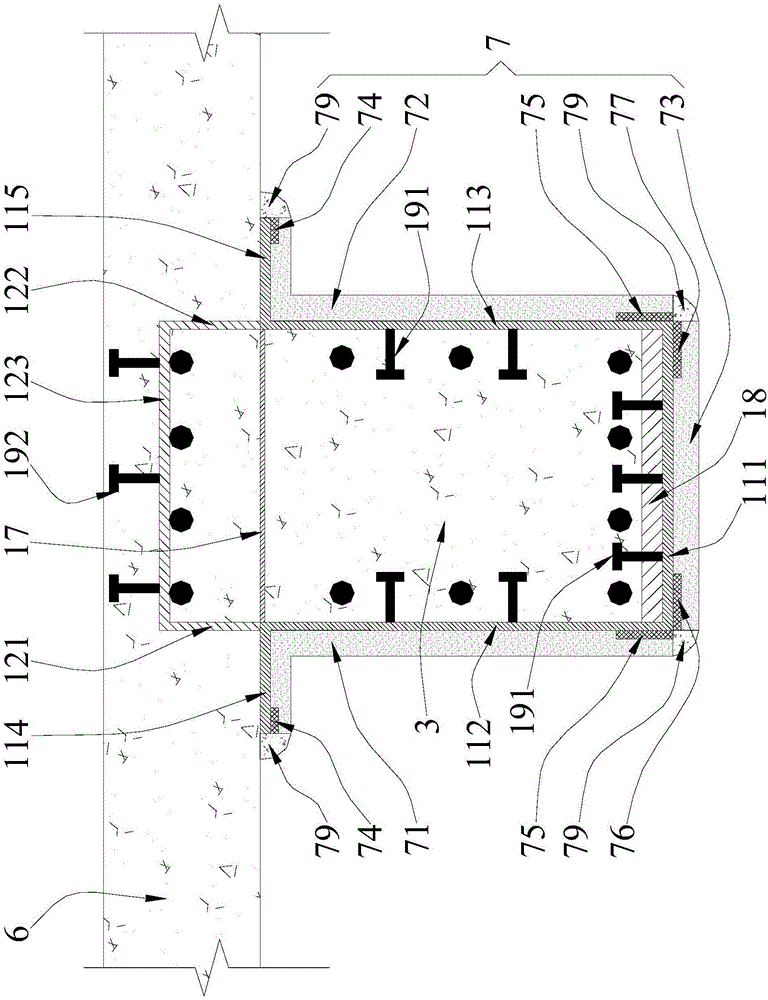

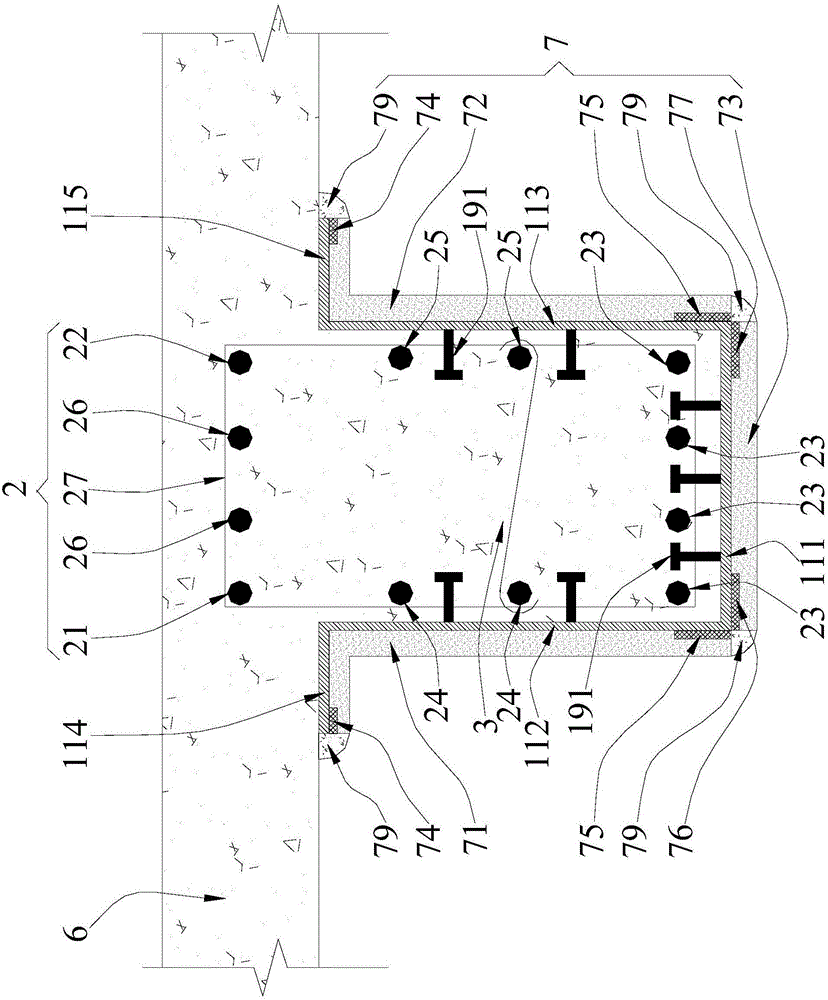

[0054] In order to enhance the connection strength between the steel frame 1 and concrete, as an improved embodiment of the present invention: the rear side of the front web 112 of the support and the front side of the rear web 113 of the support of the steel frame 1A at the left end, and the steel frame 1B in the middle The rear side of each front side beam side hoop 161 and the front side and right end of each rear side beam side hoop 162 of the steel frame 1C, the rear side of the front web 112 of the support and the front side and left end of the rear web 113 of the support The top surface of the support bottom plate 111 of the upper steel frame 1A, the top surface of the lower support bottom plate 133 of the middle steel frame 1B, and the top surface of the support bottom plate 111 of the right end steel frame 1C are welded with multiple beam inner pegs 191.

[0055] In order to enhance the connection strength between the steel frame 1 and the floor 6, as an improved embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com