Novel fixed-top awning

A top-fixing and awning technology, which is applied in sunshade, construction, building construction, etc., can solve the problems of easy corrosion, weak welding, poor durability, etc., and achieve excellent anti-aging performance, ensure excellent performance, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

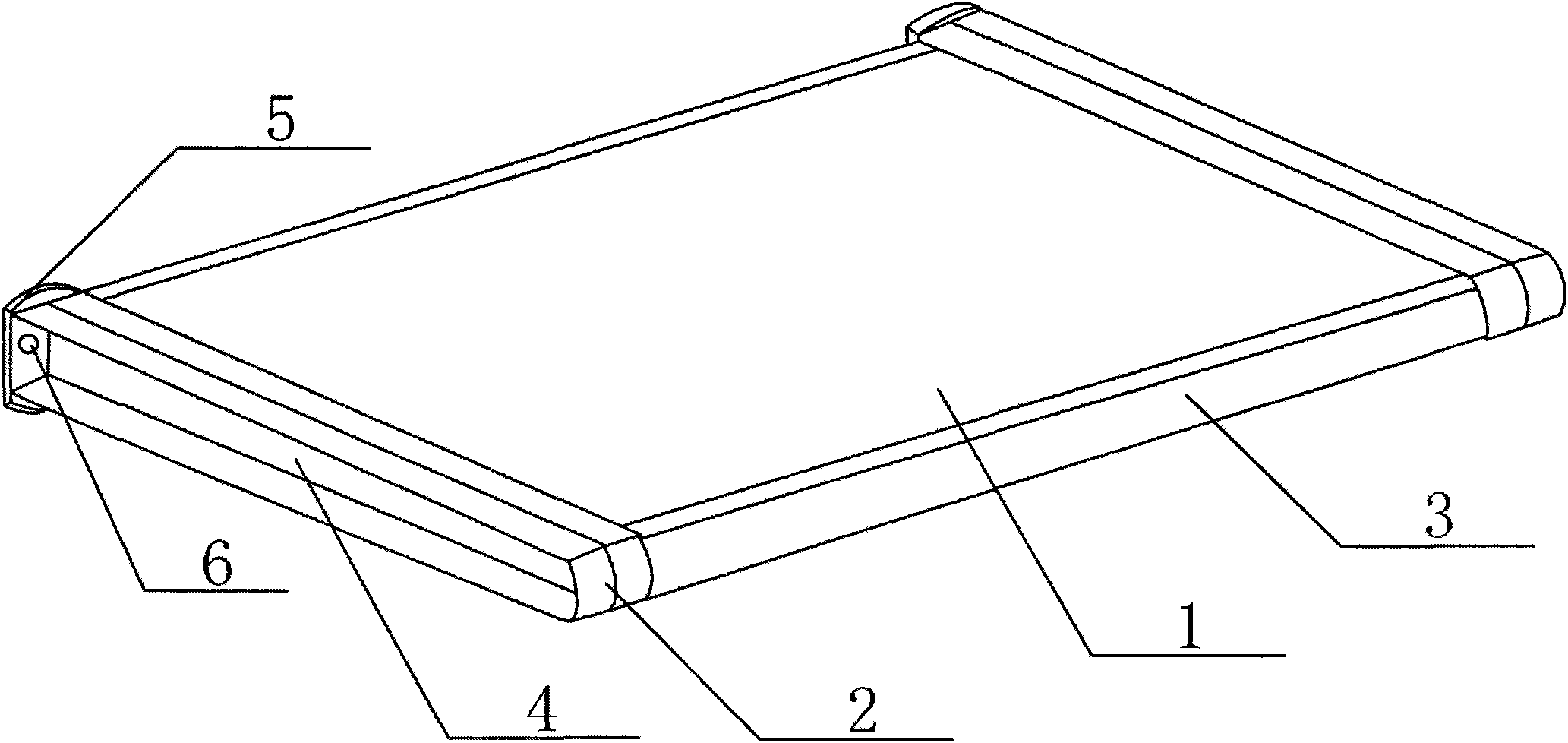

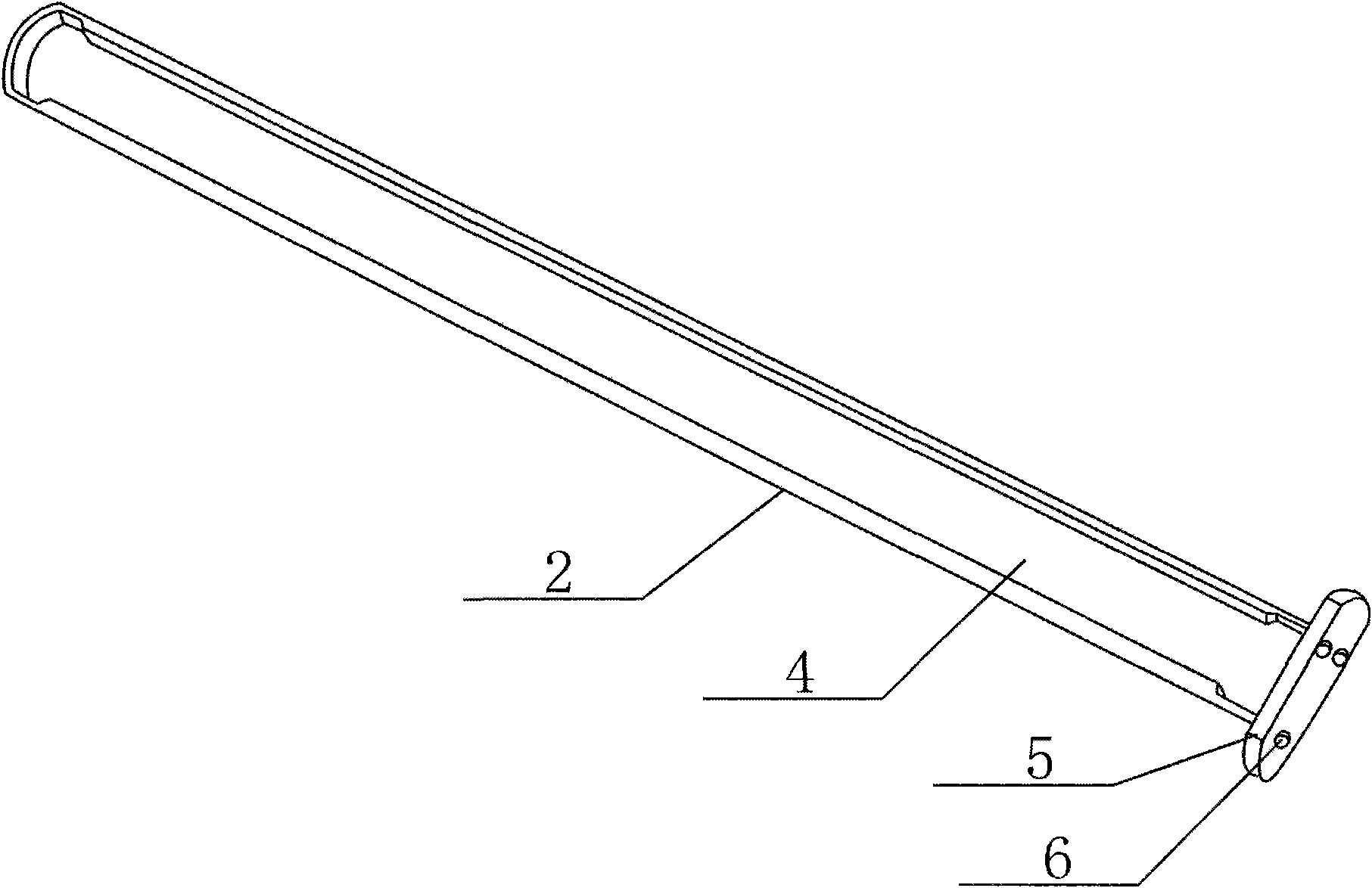

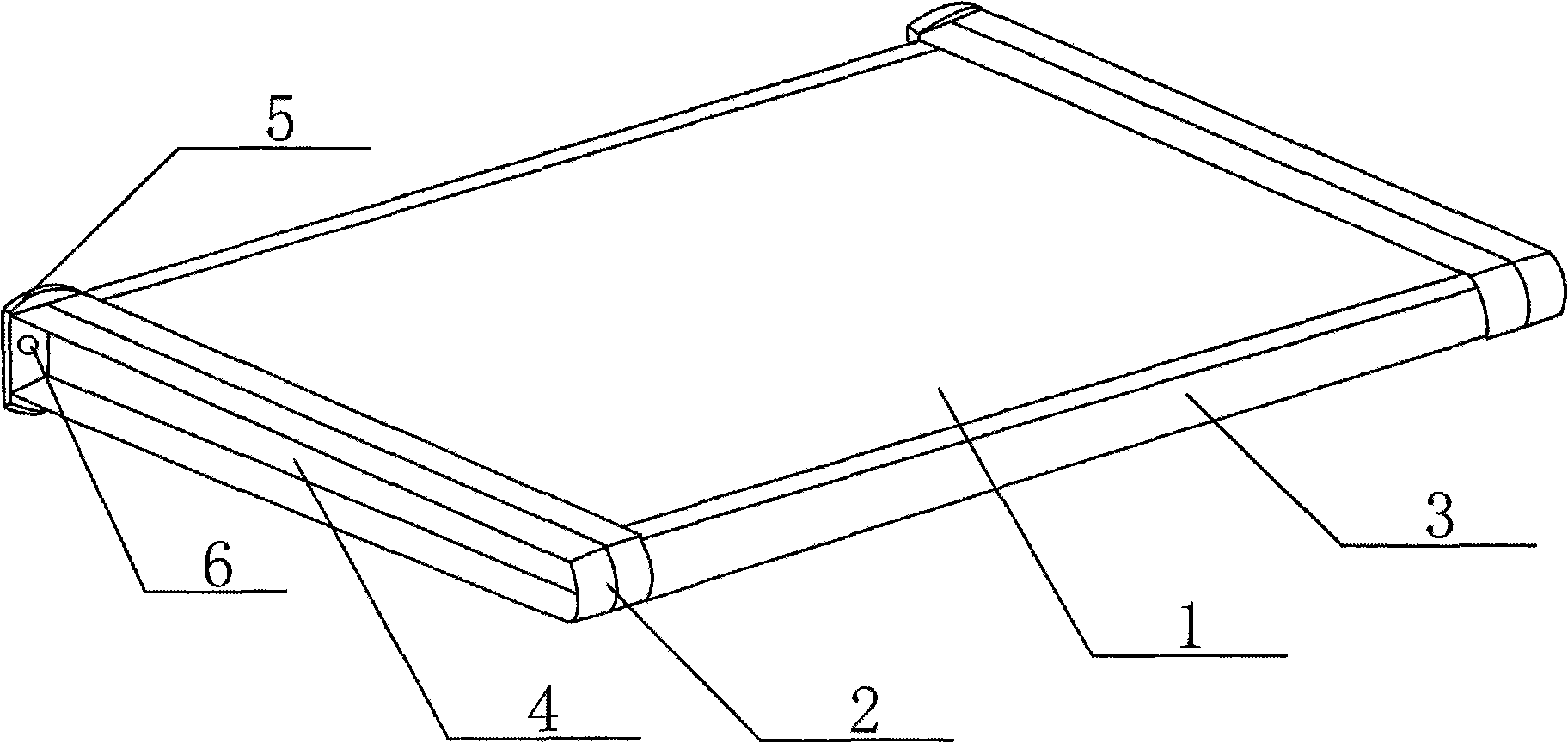

[0019] Such as figure 1 , figure 2 As shown, a new type of top-fixed rain awning is composed of awning board 1 and brackets 2 arranged on the left and right sides of the awning board 1. The front and rear sides of the awning board 1 are provided with edge strips 3, and the bracket 2 is a square four The truss structure has card slots 4 matching the two sides of the awning board 1 on the opposite sides, and the lower surface of the bracket 2 is fixedly connected with a fixing seat 5, and a mounting hole 6 is opened on the fixing seat 5; the bracket 2 is made of plastic The base material is die-casted at one time, and the composition and ratio of the plastic base material are: 70% of polypropylene PP plastic, 29% of environmentally friendly wave fiber, 0.5% of anti-aging agent, and 0.5% of ultraviolet absorber.

[0020] The card slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com