Tube check filed-type roof planting device

A planting device and tube grid technology, which is applied in the field of tube grid field roof planting devices, can solve the problems of heavy pipeline weight, high cost constraints, etc., and achieve the effects of reduced material cost, low cost and smooth water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

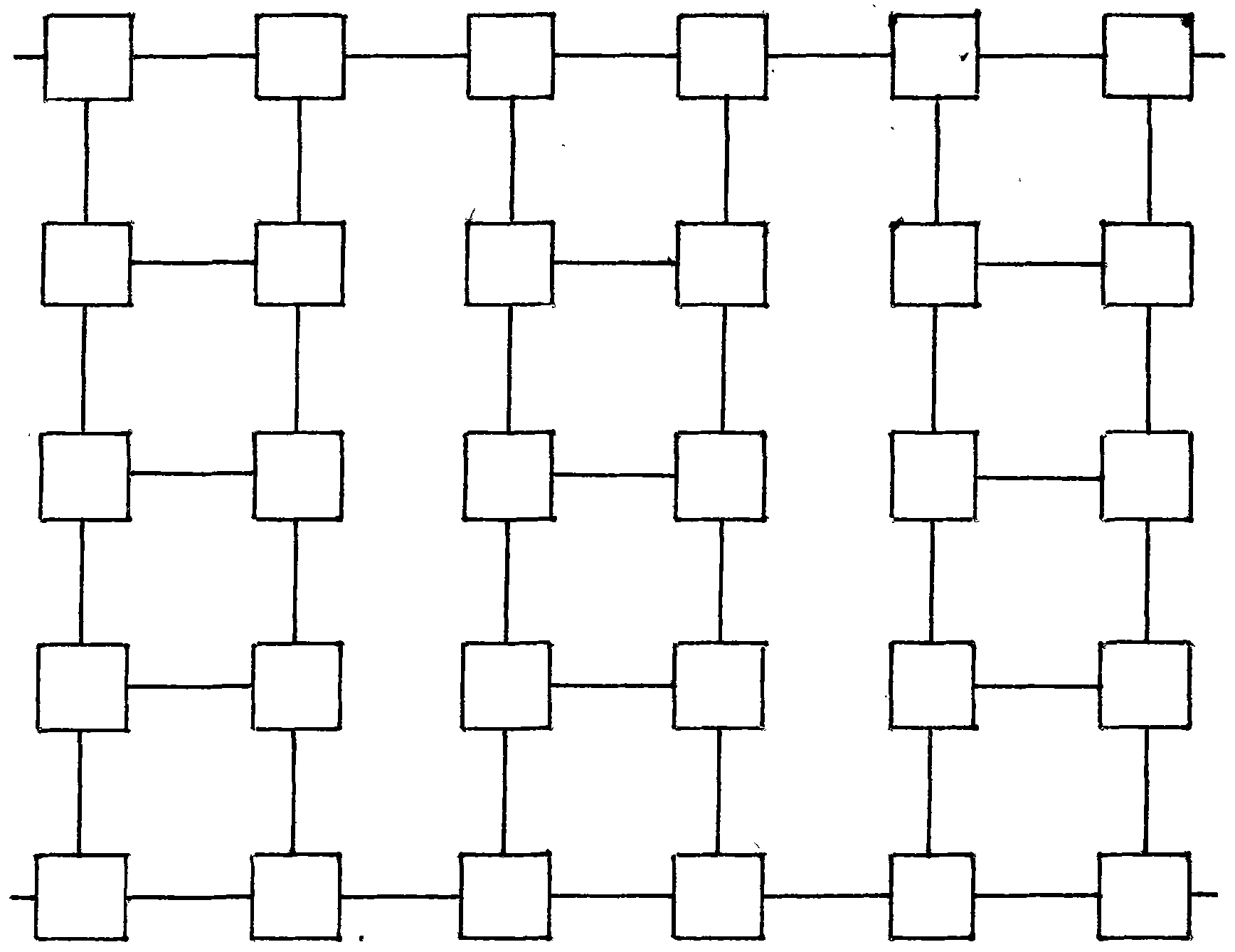

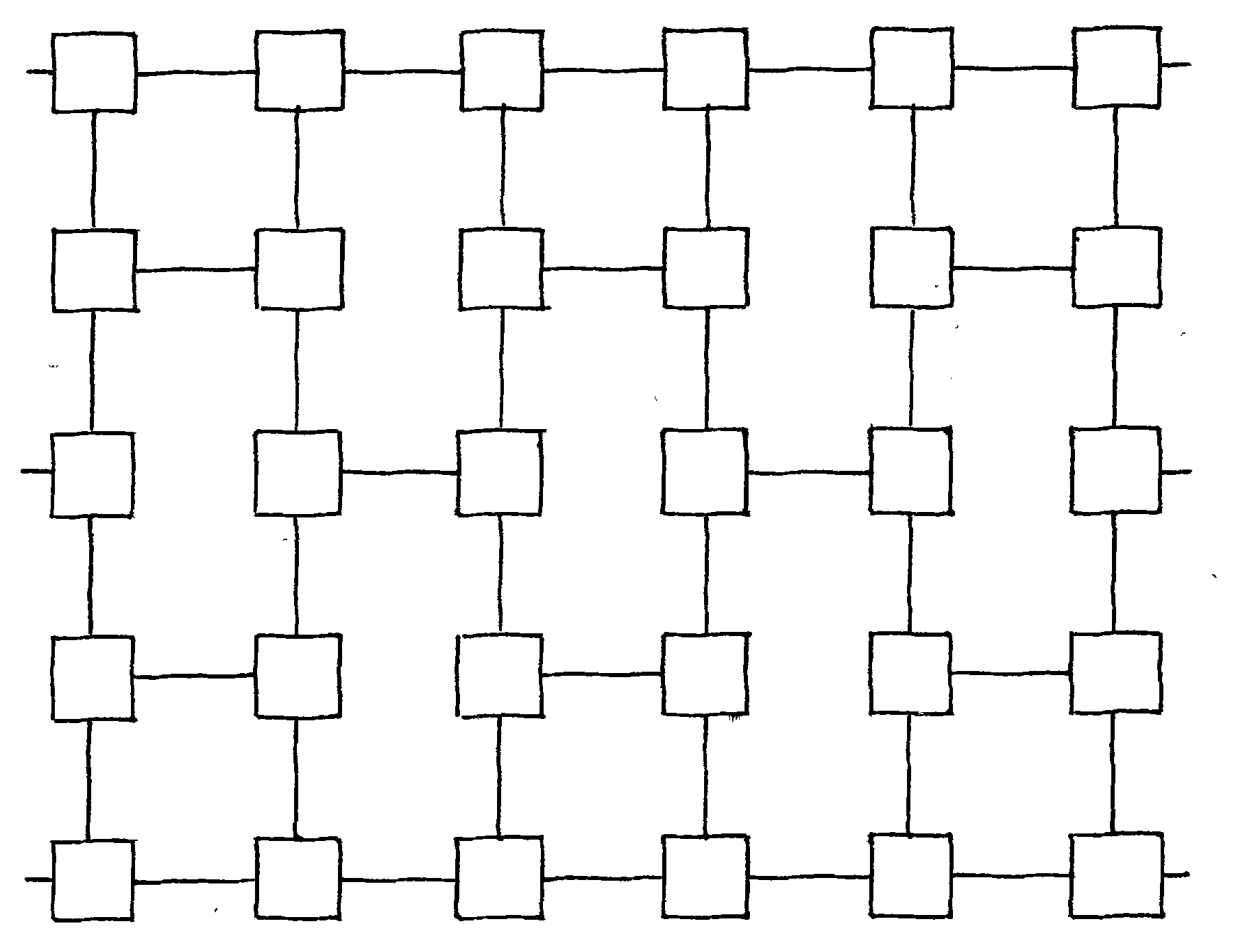

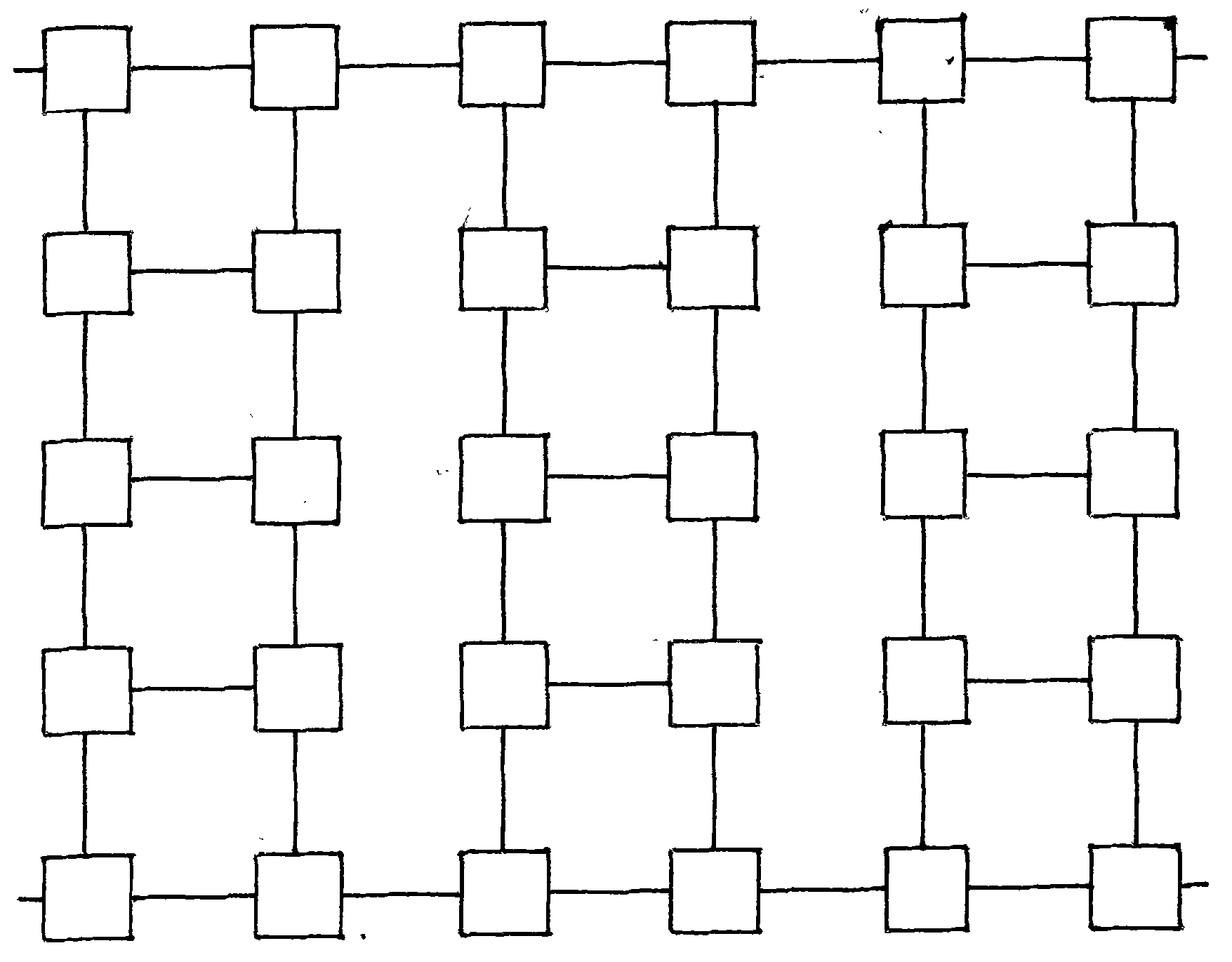

[0022] The planting cup is made of white PVC plastic injection molding with a cup mouth diameter of 50mm, a cup height of 50mm, and a closed bottom. The bottom of the cup is arranged in a T-shaped three joints, the inner diameter of the joint is 16mm, the protrusion of the joint is 15mm, and the wall thickness of the cup is 1.5mm. planting cup. Use a white wall thickness 1.5mm, ¢16mm PVC plastic pipe purchased from the market, and cut it into 150mm long sections for later use.

[0023] Use 30 planting cups and 43 sections of pipes, coat both ends of the pipes with PVC glue, insert them into the connection holes of the planting cups, connect them according to the structure of the attached drawing (1) into a pipe grid field structure with a row spacing of 20mm, place them horizontally and fix them with expansion bolts on the roof. Plug three of the remaining four connecting ports not inserted into the pipe with rubber stoppers on the tube grid roof planting device, connect one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com