High efficiency energy saving gas range

A high-efficiency and energy-saving gas stove technology, applied in the field of stoves, can solve problems such as insufficient combustion, waste of gas, and inability to prevent wind, and achieve the effects of avoiding heat loss, protecting the environment, and violent firepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

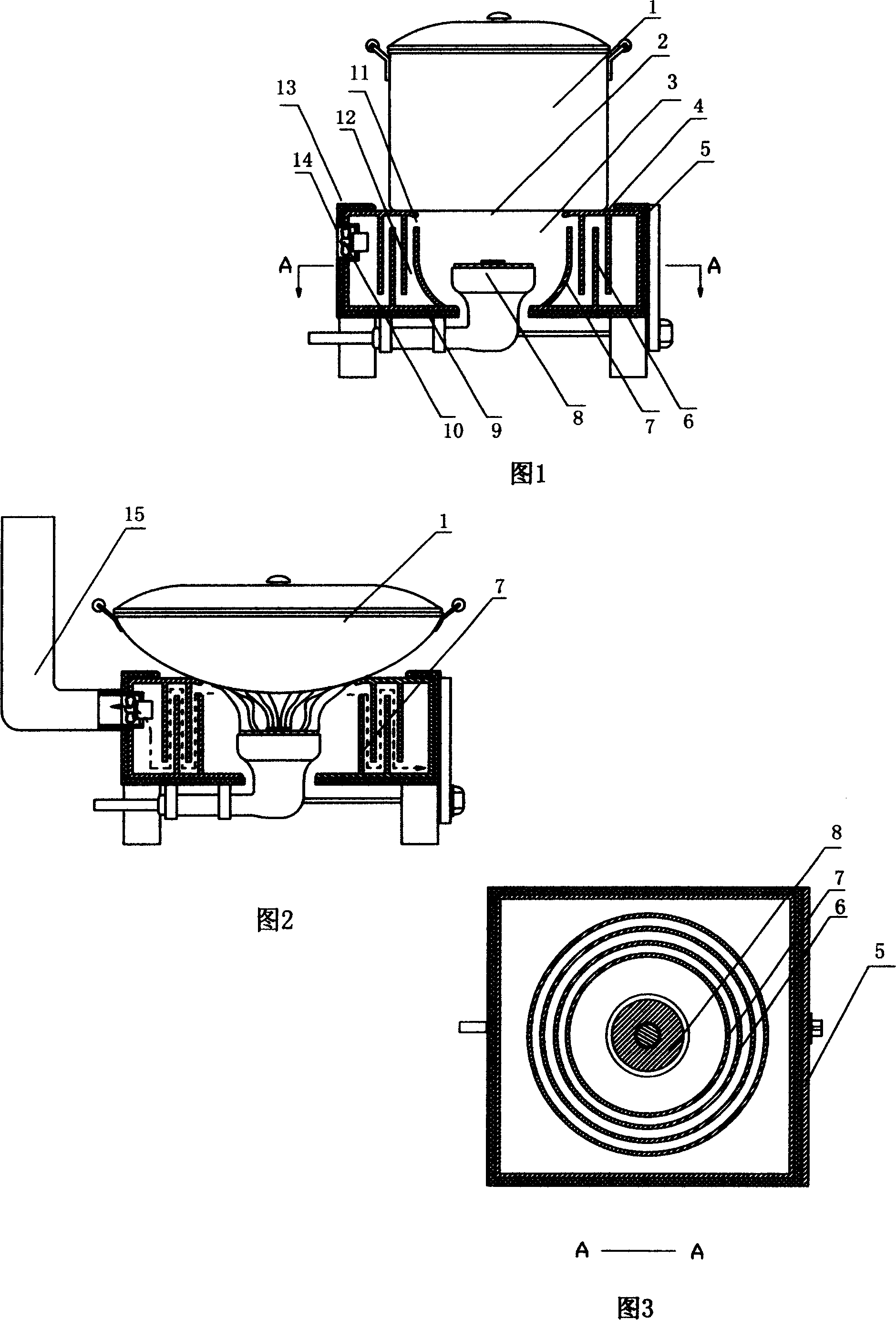

[0017] Embodiment 1: referring to Fig. 1, Fig. 2, it is made of burner 8, hearth 3, cooker body, is provided with burner 8 at the bottom of burner hearth 3, is provided with burner mouth 2 on the panel 4 of cooker body shell, in the cooker body A meandering smoke exhaust cavity 11 is arranged between the shell 13 and the furnace plate 7 , and the smoke exhaust cavity 11 is enclosed by the furnace plate 7 and several heat conducting plates 6 .

[0018] Referring to Fig. 3, the above-mentioned hearth plate 7 and heat conduction plate 6 are ring-shaped (other shapes can also be adopted according to the requirements of the shape of the stove body), wherein the hearth plate 7 is welded (or riveted, etc.) to the bottom plate 9 of the stove body shell, and the following together with) to enclose the burner; the heat conduction plate 6 is welded together with the panel 4 and the bottom plate 9 of the cooker shell respectively in an up and down staggered order. One or more inlets 11 an...

Embodiment 2

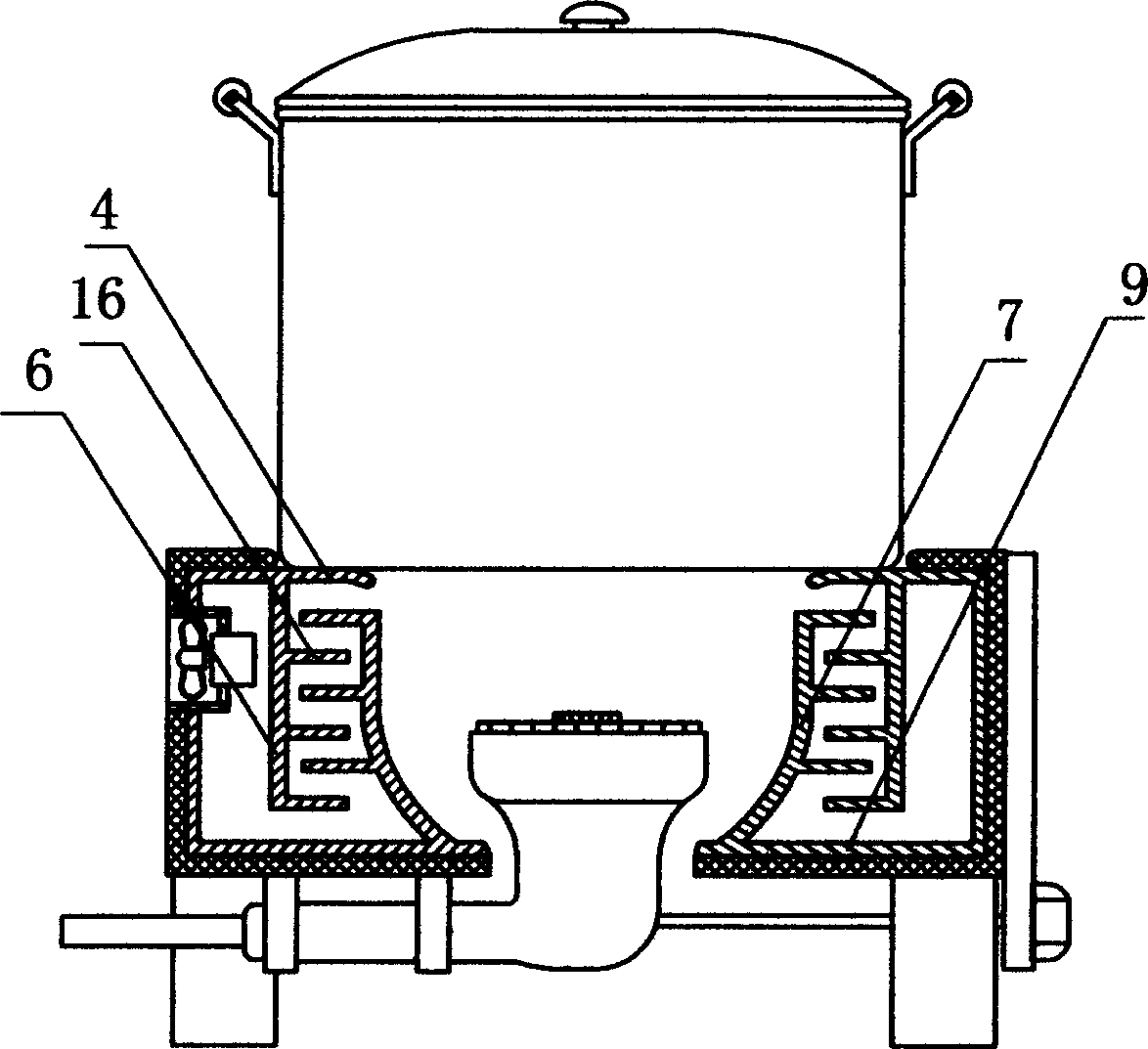

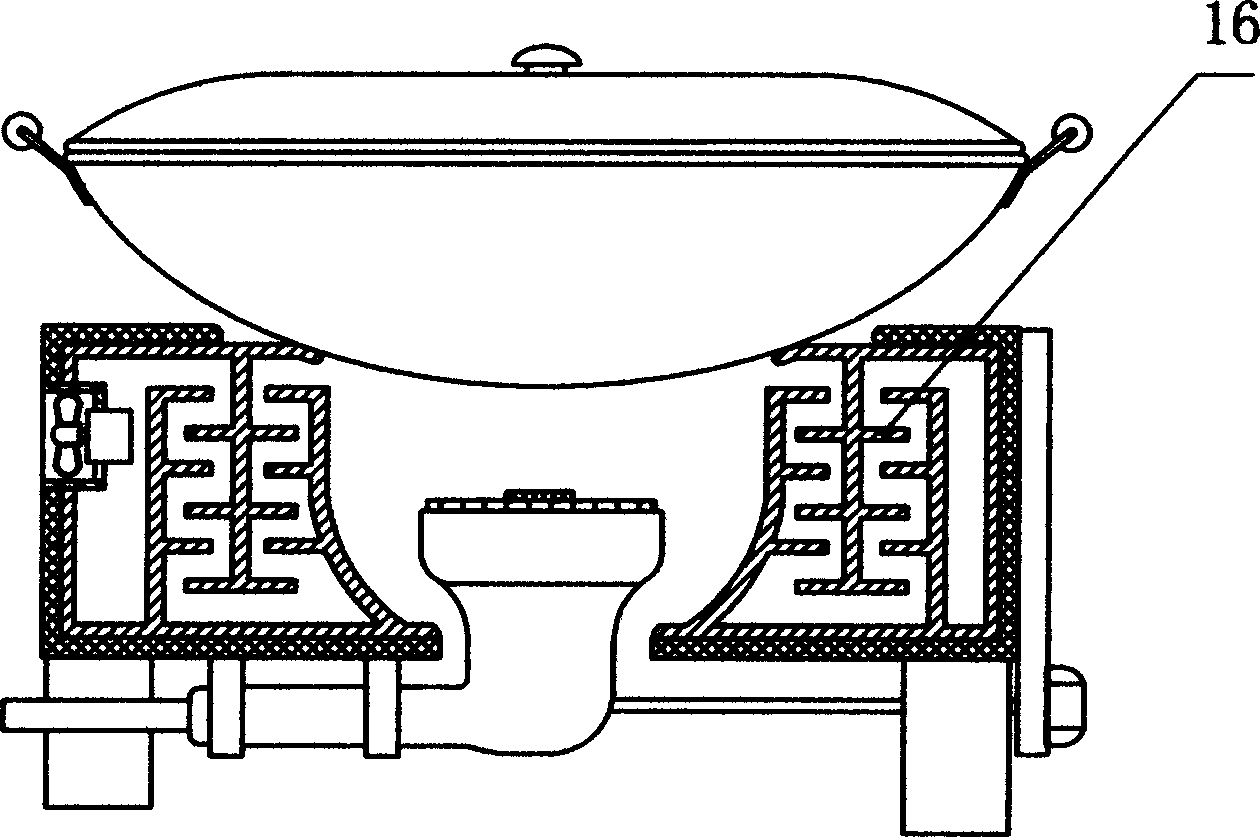

[0020] Embodiment 2: see Figure 4 , Figure 5 , the hearth plate 7 is connected to the bottom plate 9 of the cooker body shell, and a heat conducting plate 6 is connected to the panel 4 of the cooker body shell, and a number of heat conducting partitions 16 are respectively staggeredly welded on the opposite faces of the hearth plate 7 and the heat conducting plate 6 , which makes the structure more compact and can further reduce the volume of the cooker body shell 13 . In order to further enhance the heat dissipation effect of the flue gas, a plurality of heat conduction plates can be arranged in a staggered order up and down to connect with the panel and the bottom plate of the stove body shell respectively, and the opposite surfaces of the two adjacent heat conduction plates are also staggeredly welded. There are several heat-conducting partitions 16 to further increase the contact area with the flue gas, but this also increases the resistance of the flue gas flow, so it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com