Biomass fuel based on corn straw, and preparation method and preparation production line thereof

A technology of biomass fuel and corn stalks, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of inability to use substrate materials, inability to provide fuel products, low energy density, etc., achieve good automatic production effect, and benefit The effect of high-efficiency production and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

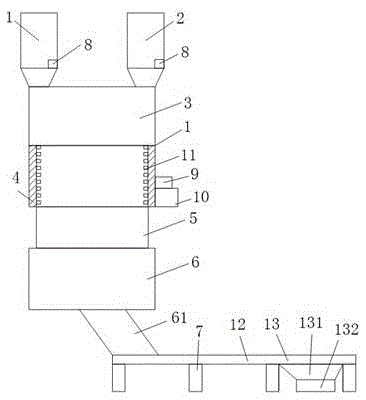

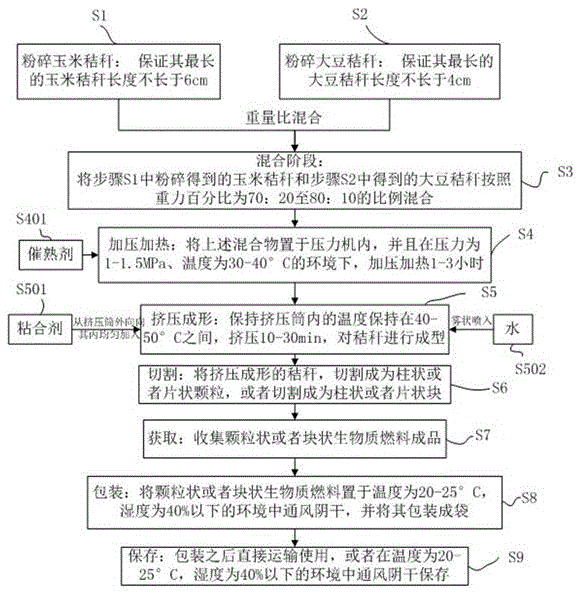

[0034] At least 620kg of corn stalks and at least 220kg of soybean stalks are respectively put into the first crushing device and the second crushing type for crushing, and 620kg of short corn stalks and 220kg of short soybean stalks are measured by an electronic weighing device.

[0035] After the metering is finished, add 2.6kg of baking soda expansion agent and 35kg of quick lime and calcium carbonate mixed ripening agent in the mixing equipment, start the mixing equipment 3 and mix the corn stalk short chips, soybean straw short chips, ripening agent and expansion agent. Stir well.

[0036] After the above-mentioned mixing stage is finished, the above-mentioned product is placed in the pressurized heating device 4 for pretreatment before extrusion, the above-mentioned mixture is placed in the press, and the pressure is 1-1.5MPa, the temperature is 30-40 ° C Under the environment, pressurize and heat for 1.2 hours. The semi-finished product that pressurization heat treatme...

Embodiment 2

[0040] At least 780kg of corn stalks and at least 205kg of soybean stalks are put into the first crushing device and the second crushing type for crushing respectively, and 780kg of short corn stalks and 205kg of short soybean stalks are measured by an electronic weighing device.

[0041] After the metering is finished, add 2.6kg of alum puffing agent and 45kg of quicklime and calcium carbonate mixed ripening agent into the mixing equipment, start the mixing equipment 3 and mix and stir uniform.

[0042] After the above-mentioned mixing stage is finished, the above-mentioned product is placed in the pressurized heating device 4 for pretreatment before extrusion, the above-mentioned mixture is placed in the press, and the pressure is 1-1.5MPa, the temperature is 30-40 ° C Under the environment, pressurize and heat for 1.2 hours. The semi-finished product that pressurization heat treatment finishes is put into the extrusion molding machine 5 that is provided with below it and k...

Embodiment 3

[0046] At least 700kg of corn stalks and at least 190kg of soybean stalks are put into the first crushing device and the second crushing type for crushing respectively, and 700kg of short corn stalks and 190kg of short soybean stalks are measured by an electronic weighing device.

[0047] After the metering is finished, add 2.7kg of ammonium nitrate puffing agent and 38kg of banana powder ripening agent into the mixing equipment, start the mixing equipment 3 to mix the corn stalk short chips, soybean straw short chips, ripening agent and puffing agent and stir evenly.

[0048] After the above-mentioned mixing stage is finished, the above-mentioned product is placed in a pressurized heating device 4 for pretreatment before extrusion, and the above-mentioned mixture is placed in a press, and the pressure is 12MPa, and the temperature is 35-40°C. , heated under pressure for 1.5 hours. The semi-finished product that pressurization heat treatment finishes is put into the extruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com