Lifting device for construction machinery

A lifting device and construction machinery technology, applied in the direction of lifting devices, lifting frames, cleaning methods using liquids, etc., can solve the problems of increasing the difficulty of internal cleaning, unstable lifting process, and potential safety hazards, and achieve stable lifting, Avoid safety hazards and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

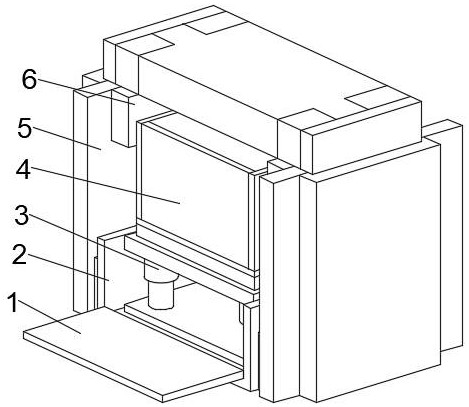

[0040] see Figure 1-6 , the present invention provides a technical solution: a construction machinery lifting device, including a fixed base 2, the bottom of the outer wall on both sides of the fixed base 2 is fixedly connected with a lifting protection frame 5, and the lifting protection frame 5 is close to one side of the fixed base 2 A moving plate 6 is arranged in the middle of the side top, a closing plate 1 is arranged on the front bottom of the fixed base 2, a sliding bracket 3 is fixedly connected to the bottom of the inner cavity of the fixed base 2, and a placement device is arranged on the top of the inner walls of both sides of the sliding bracket 3 4;

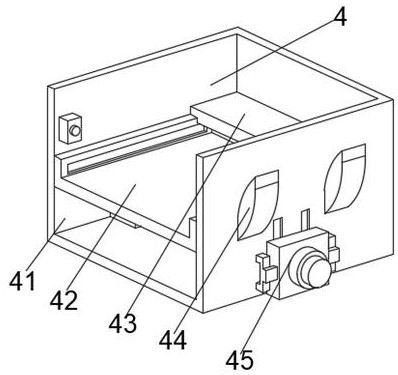

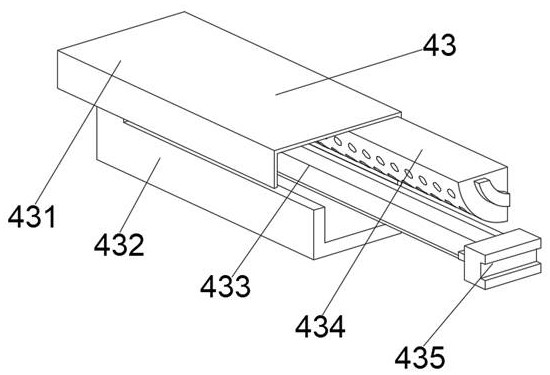

[0041] The placement device 4 includes a placement frame 41, an auxiliary part 42 is fixedly connected to the middle of both sides of the inner wall of the placement frame 41, a cleaning mechanism 43 is provided on the back top of the auxiliary part 42, and an anti-slip mechanism 45 is provided at the middle of th...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method of using a construction machinery lifting device, step 1: install the device, connect the closing plate 1 with the fixed base 2, and fix the The base 2 is connected with the lifting protection frame 5, so that the moving plate 6 moves vertically on the lifting protection frame 5, and the moving plate 6 is connected with the placement device 4;

[0048] Step 2: Carry out the intermittent movement of the cleaning mechanism 43 in the horizontal direction through the sliding structure generated by the placing frame 41 and the auxiliary parts 42, connect the buffering inclined block 44 with the placing frame 41, and carry out after the lifting and lowering of the placing frame 41 stops. fixed;

[0049] Step 3: Move the scraper plate 433 by using the movable cavity formed by the protective top cover 431 and the transition box 432, and connect the linkage block 435 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com