Method for making perspiration eliminating and ventilating shoes

A production method and technology for breathable shoes, which are applied in the field of clothing, can solve the problems of underdeveloped industry, rough workmanship, and the function of breathable and sweat-absorbing cannot keep up with the cloth shoes with a layered bottom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the invention.

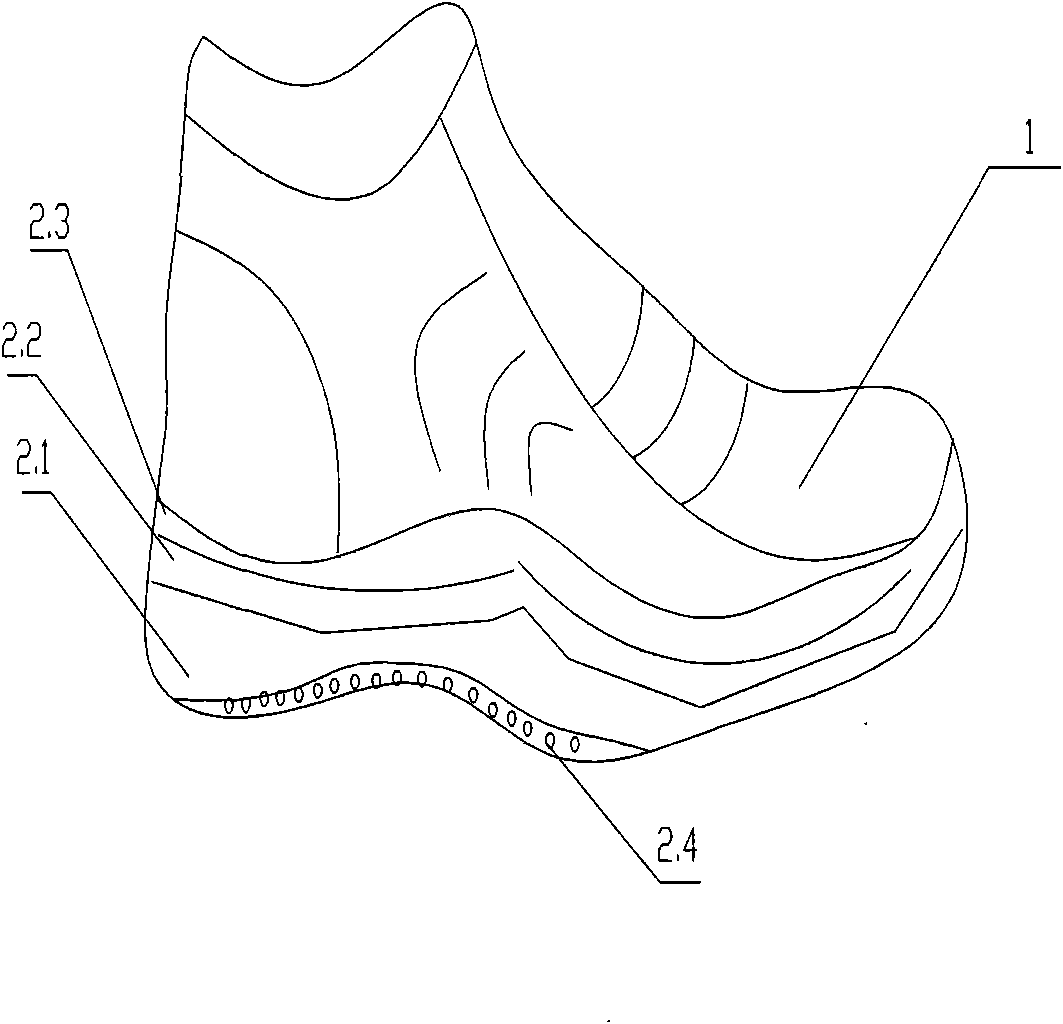

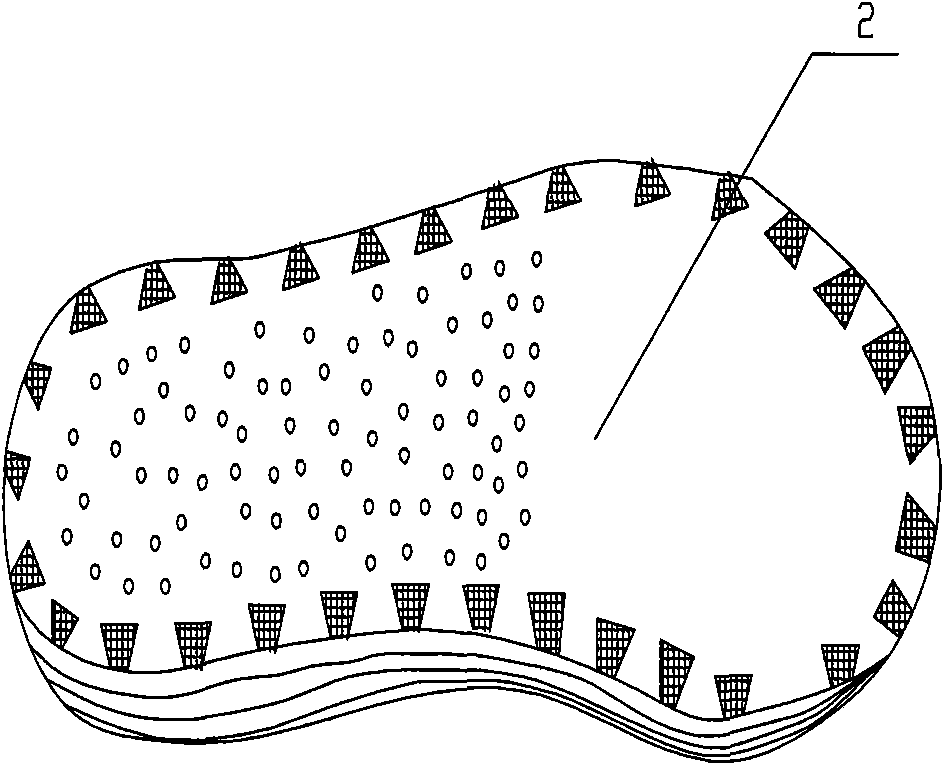

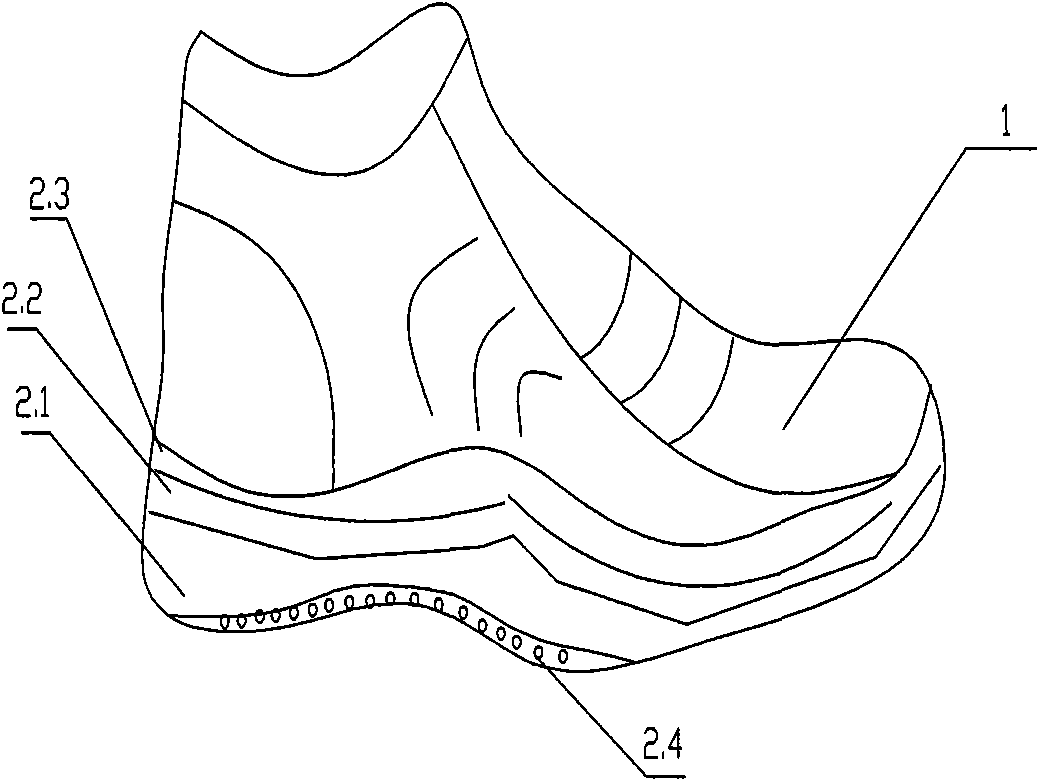

[0012] Such as Figure 1-2 Shown, a kind of manufacture method of perspiration breathable shoes, comprises making vamp 1 and sole 2;

[0013] Among them, making vamp 1 is to design various vamp styles according to needs, such as casual shoes, leather shoes, sandals, sports shoes and other vamps;

[0014] The making of the shoe sole 2 includes three processes: firstly making the layered cloth bottom 2.2, secondly designing the non-woven fabric deodorant insole 2.4, and finally casting the chemical layer 2.1 on the bottom surface of the layered cloth bottom 2.2 by an injection molding process;

[0015] Among them, the chemical layer 2.1 is provided with ventilation holes 2.4;

[0016] Finally, the sole 2 and the vamp 1 are connected together to make a sweat-wicking and breathable shoe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com