Alcoholysis-resistant polyamide resin as well as preparation method and application thereof

A polyamide resin and alcoholysis-resistant technology, which is applied in the field of polyamide resin, can solve the problems of changing mechanical properties, reducing the overall polarity of materials, reducing water absorption, etc., and achieves good surface properties, good mechanical properties, and good hydrolysis resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

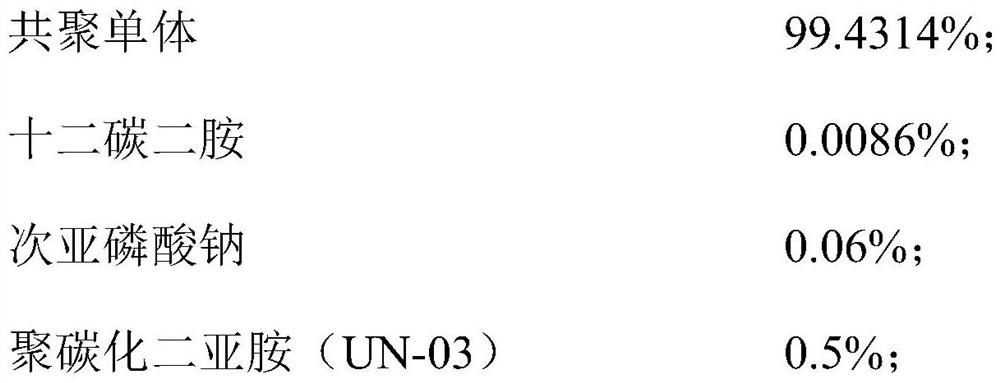

[0083] The present embodiment provides a kind of alcoholysis-resistant polyamide resin (relative viscosity is 2.40), comprises the raw material component of following mass percent:

[0084]

[0085] Wherein, the comonomer includes the following components in mass percentage: 92% of nylon 66 salt, 5% of nylon 612 salt and 3% of nylon MXD6 salt, and the alcoholysis-resistant agent consists of two (2,6-diisopropylphenyl) carbon Diimide and polycarbodiimide (UN-03) are composed at a mass ratio of 1:2.

[0086] The preparation method of above-mentioned alcoholysis-resistant polyamide resin is as follows:

[0087] (1) Joining the comonomer solution that the mass concentration is 57% into the concentration tank that the pressure is 0.25MPa concentrates, the comonomer solution that the mass concentration is 80% after concentration, the hexamethylenediamine that the mass concentration is 50% The solution and sodium hypophosphite are reacted in a nitrogen atmosphere, and the polyami...

Embodiment 2

[0091] The present embodiment provides a kind of alcoholysis-resistant polyamide resin (relative viscosity is 2.60), comprises the raw material component of following mass percent:

[0092]

[0093] Wherein, the comonomer comprises the following components in mass percentage: 80% of nylon 66 salt, 15% of nylon 610 salt and 5% of nylon 6T salt; ), epoxy polymer hydrolysis resistance agent (Sanwell AH81) in a mass ratio of 1:1.

[0094] The preparation method of above-mentioned alcoholysis-resistant polyamide resin is as follows:

[0095] (1) Adding the nylon salt solution with a mass concentration of 56.75% and the laurolactam solution with a mass concentration of 50% into a concentration tank with a pressure of 0.25MPa for concentration, the concentrated comonomer with a mass concentration of 80% solution, the end-capping agent solution with a mass concentration of 50%, and sodium hypophosphite react under nitrogen protection, and after temperature and pressure increase, p...

Embodiment 3

[0099] The present embodiment provides a kind of alcoholysis-resistant polyamide resin (relative viscosity is 3.10), comprises the raw material component of following mass percent:

[0100]

[0101] Wherein, the comonomer includes the following components in mass percentage: 86% of nylon 66 salt, 10% of nylon 612 salt and 4% of nylon 6I salt.

[0102] The preparation method of above-mentioned alcoholysis-resistant polyamide resin is as follows:

[0103] (1) be that the comonomer solution that mass concentration is 57% joins in the concentrator tank that pressure is 0.2MPa and concentrates, and the comonomer solution that mass concentration is 75% after concentrating, mass concentration is the ammonia monohydrate of 45% The solution and sodium hypophosphite were reacted under the protection of nitrogen, and the polyamide polymer was obtained after increasing the temperature and pressure, keeping the pressure and increasing the temperature, releasing the pressure and vacuumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com