Pressure circulating washing machine with forced jet water flow

A water jet and washing machine technology, applied in the field of washing machines, can solve problems such as shortening the washing process, and achieve the effects of uncomplicated production process, increased washing volume, and single washing machine structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

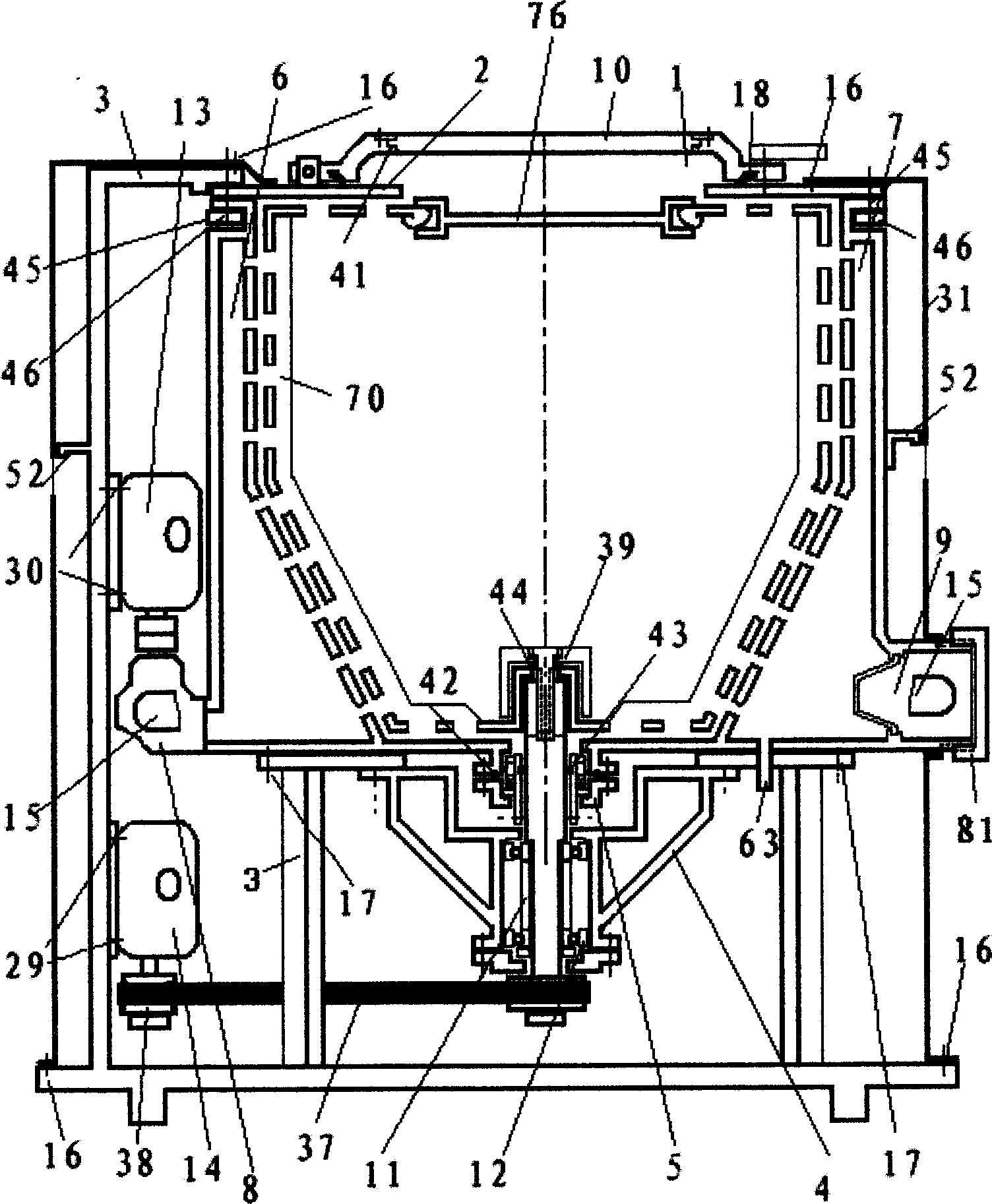

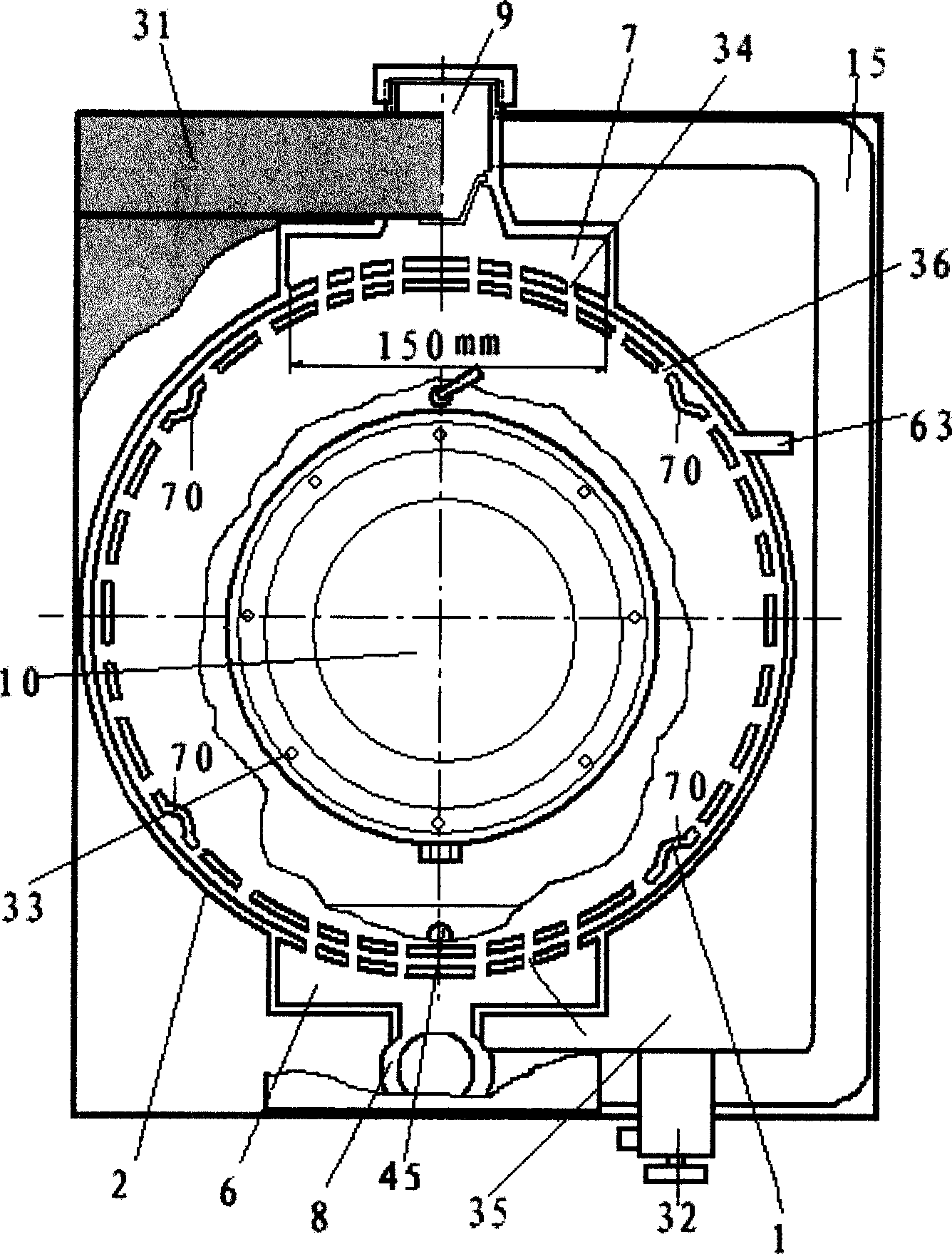

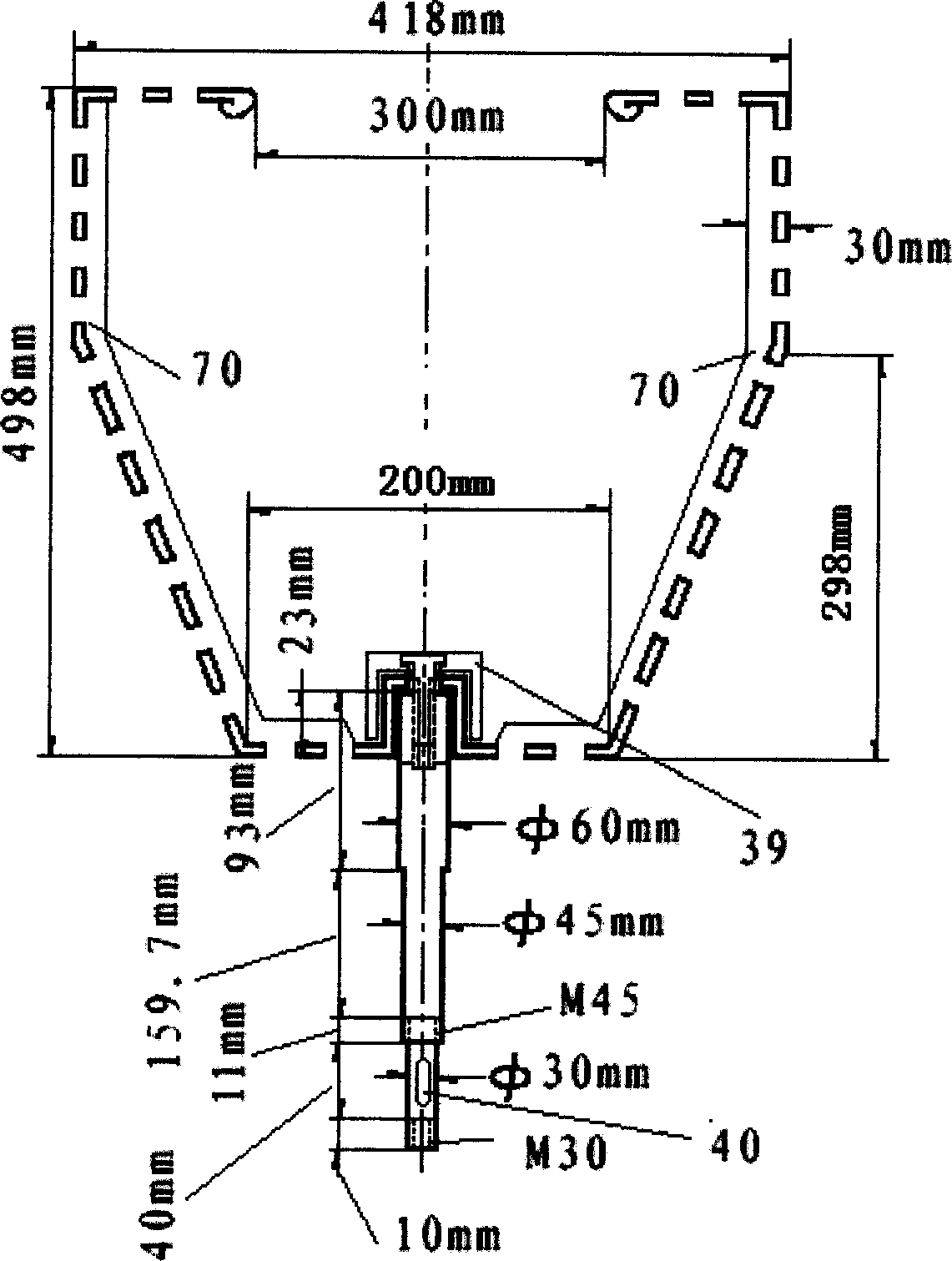

[0024] The washing machine structure of the present invention adopts figure 1 Embodiment is in order to consider that the structural design of the washing machine of the present invention can meet the requirements of the washing machine of the present invention in terms of full-automaticity. figure 1 The structure of the embodiment can not only use the drum to dry the clothes, but also can take out the clothes without draining the water when the washing water is not dirty, thereby saving water and detergent consumption. The drum adopts a small structure with an upper big bottom, so that the clothes can automatically fall before drying, and the clothes can be put into the center to reduce the unbalanced force generated by it. Simultaneously, when the washing machine of the present invention washes the clothes, the high-speed water flow can generate a certain lifting force on the clothes, thereby improving the cleaning degree of the clothes by the washing machine of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com