Parallel drying clothes hanger and clothes hanging ring

A clothes hanger and parallel connection technology, applied in the field of bearing racks, can solve the problems of increased cost, complex structure, increased area and volume of bearing rods, etc., and achieve the effects of reduced diameter and pipe wall thickness, fewer connection points, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

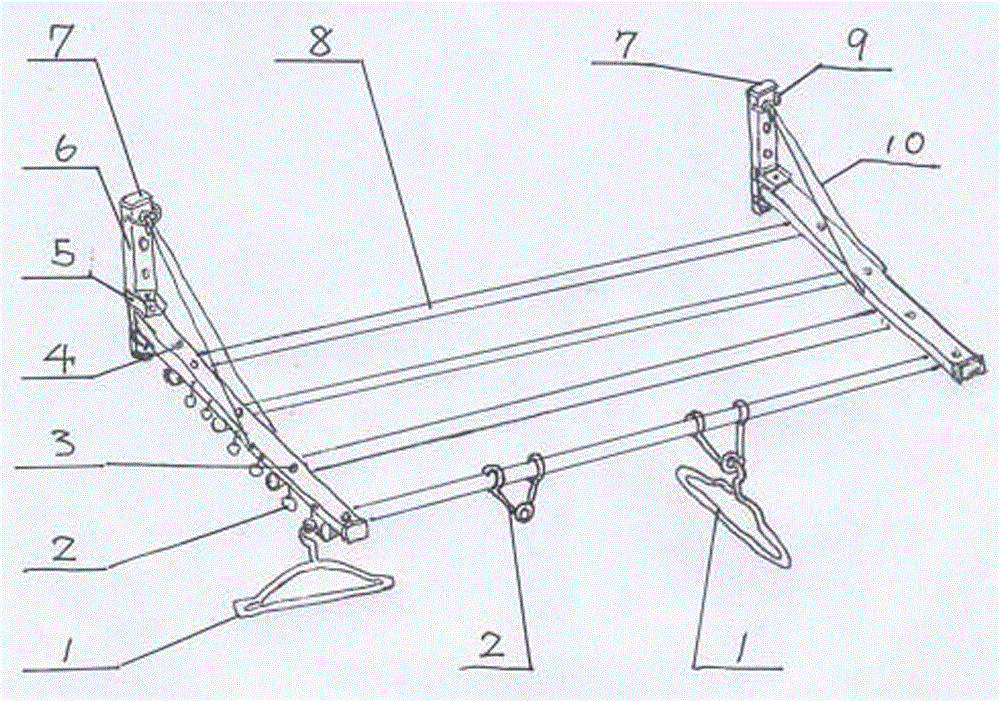

[0026] Refer to attached figure 1 , the cross bar [8] is a direct and indirect load-bearing bar, and the vertical bar [4] is an indirect load-bearing bar. The cross-section of the longitudinal bar [4] is a rectangular stainless steel tube, several hinge holes [3] are established on the center line, each hinge hole [3] is arranged according to the corresponding distance, and the hinge hole [3] at the rear end is connected to the hinge seat [5]. connected. The two ends of the cross bar [8] are provided with hinge holes, and the hinge holes at the two ends of more than two cross bars [8] are to be connected with the corresponding hinge holes [3] of the vertical bar [4] by the hinge shaft to form a parallelogram frame. The hinge shaft can be a bolt or a rivet. After the hinge shaft is connected, there is relative frictional force between the vertical bar [4] and the cross bar [8], which can prevent the closing of the airing clothes hanger that is opened when carrying clothes under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com