Washing machine capable of rubbing clothes

A washing machine and main motor technology, which can be applied to other washing machines, washing devices, energy and waste water treatment, etc., can solve the problems of inability to achieve rubbing, low efficiency, time-consuming and power-consuming, etc., to shorten the washing time, prevent environmental pollution, reduce load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

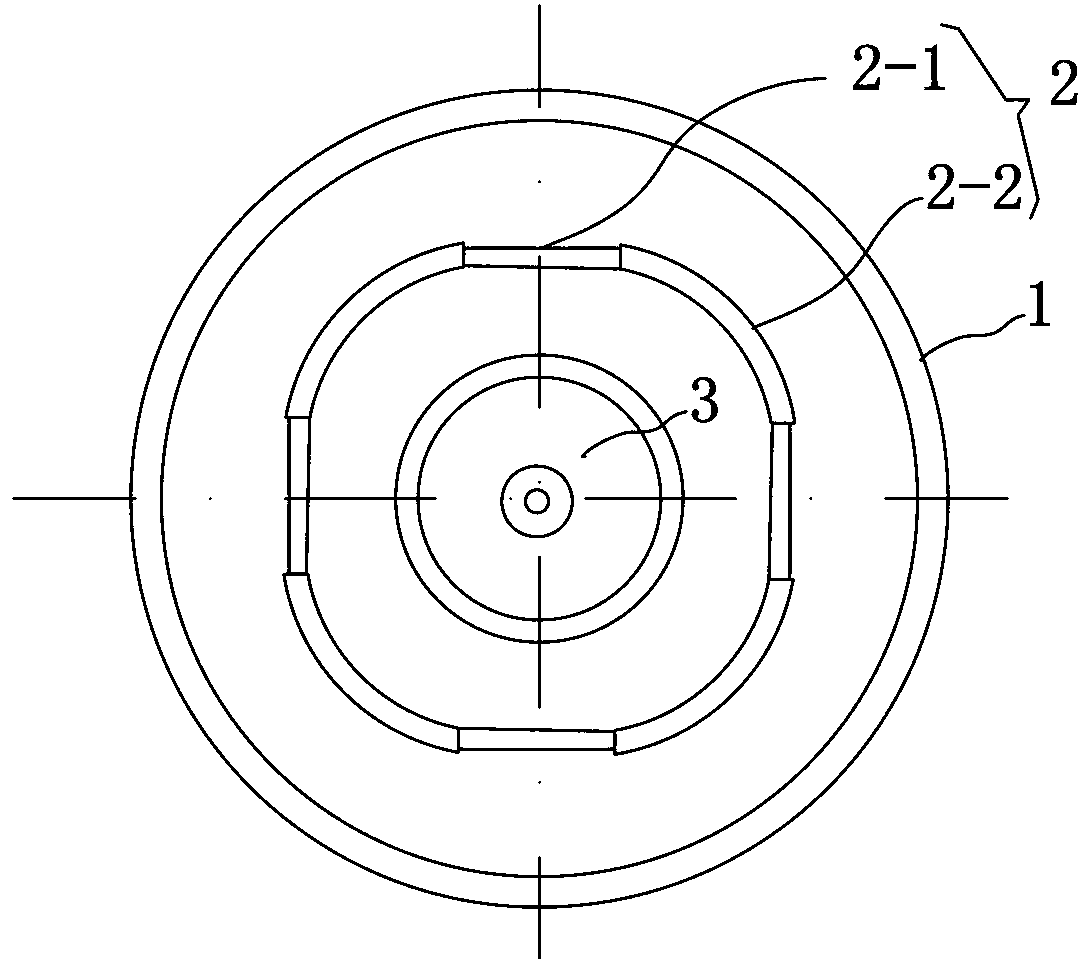

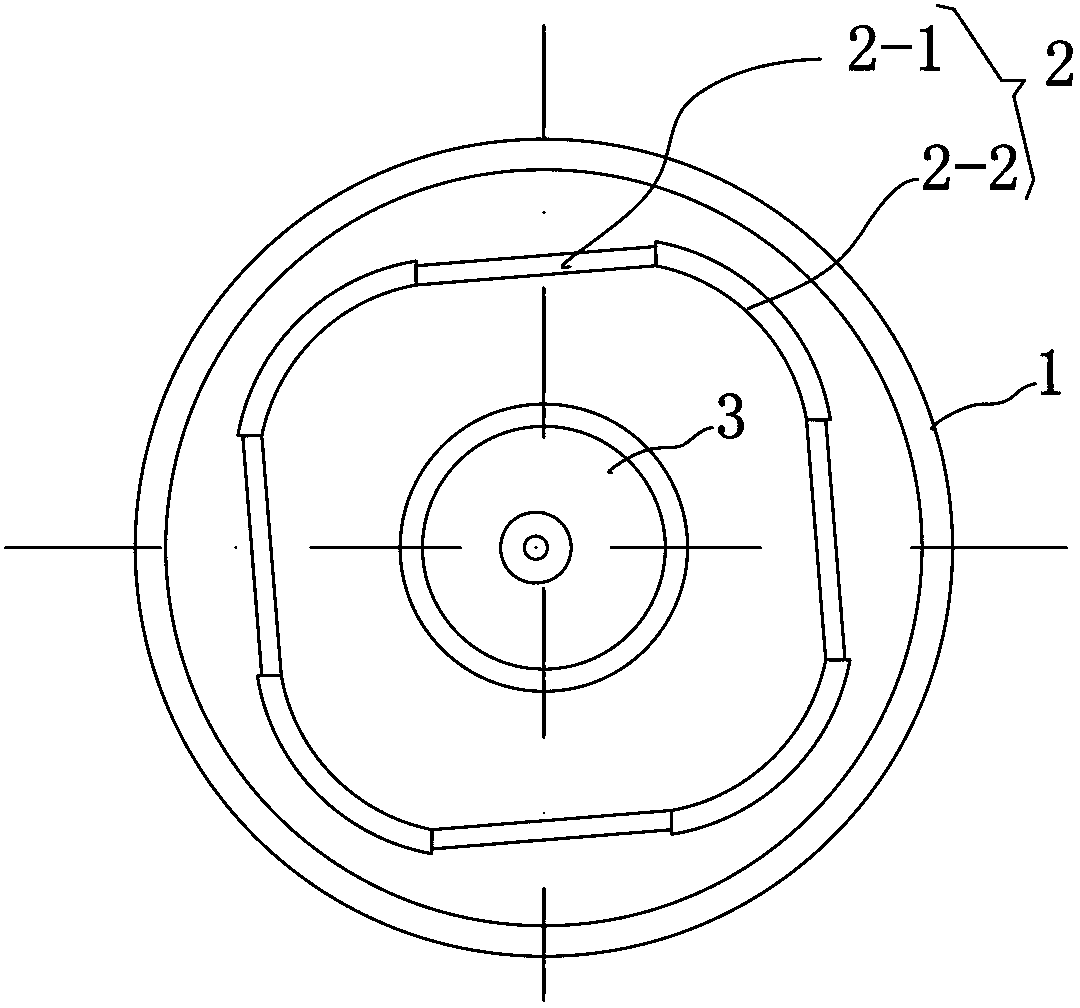

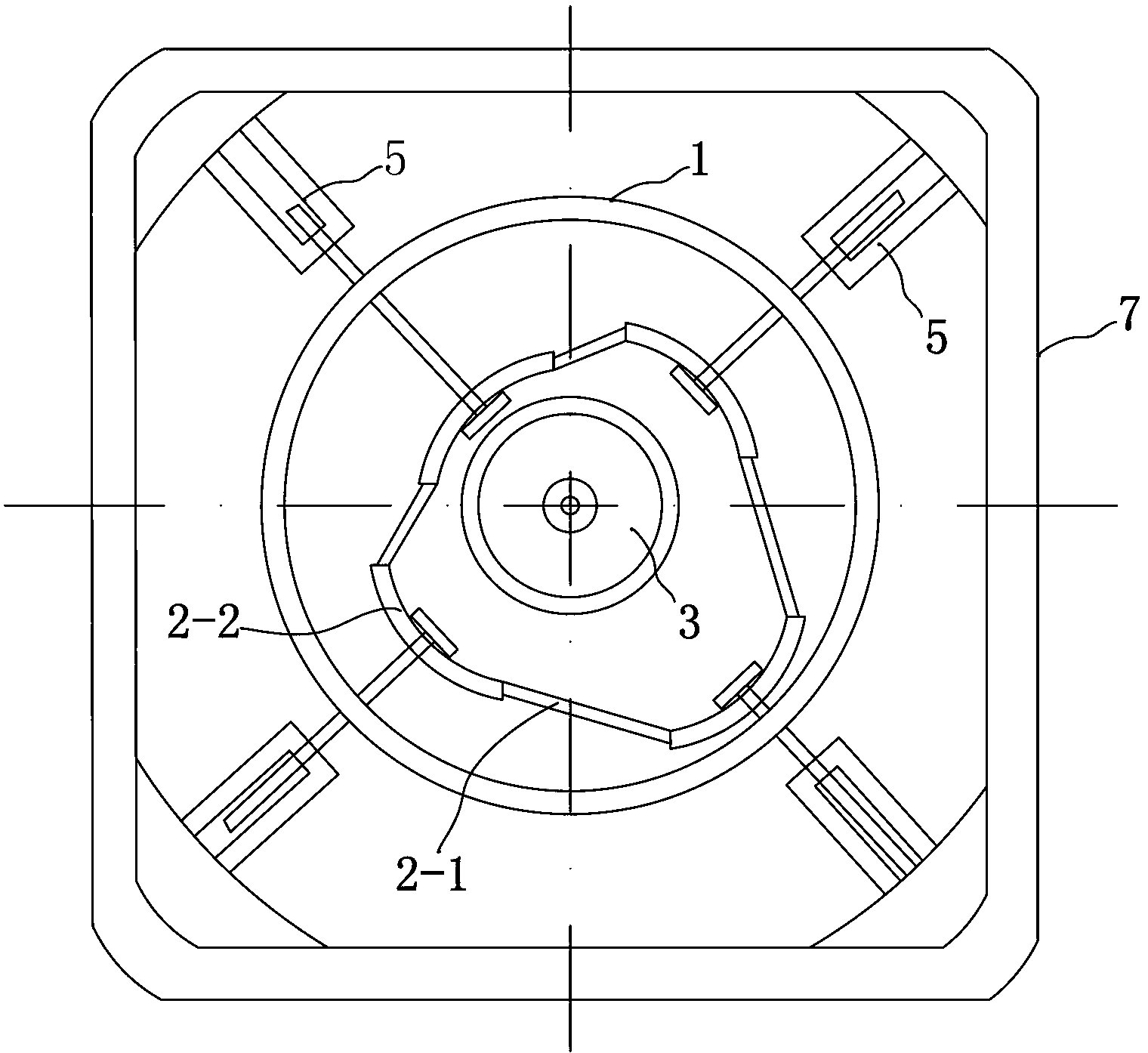

[0017] See Figure 1-5 , the washing machine of this embodiment comprises: an outer tub 1, an inner tub 2 arranged in the outer tub 1, and a dial 3 arranged in the inner tub 2; the dial 3 is driven by a main motor, and the output shaft of the main motor is connected with the The outer barrel 1 is connected to the inner barrel 2; the inner barrel 2 includes at least 2 pairs of elastic petals 2-1 and non-elastic petals 2-2 for connecting successively into barrels, and the walls of the non-elastic petals 2-2 are distributed with A through hole that is only open when the washing machine is performing a spin cycle.

[0018] Each non-elastic petal body 2-2 is distributed along the outer edge of the dial 3, and each non-elastic petal body 2-2 is connected with a connecting rod 5 for controlling its radial displacement, and the connecting rod 5 is connected with a driving mechanism; When performing the washing and rinsing procedures, with the rotation of the dial 3, the driving mecha...

Embodiment 2)

[0028] See Image 6 , apply the water treatment system of the washing machine in the above embodiment, comprising:

[0029] The water storage tank 21 is used to collect the waste water discharged from the washing machine;

[0030] Wastewater evaporating device 22 is used to be arranged on the air exhaust side of air conditioner outdoor unit 23 and connected to said water storage tank 21, so as to utilize the hot air discharged by air conditioner outdoor unit 23 to evaporate said waste water;

[0031] The waste water evaporating device 22 includes multi-layer evaporating pans 221 arranged up and down, and the waste water from the water storage tank 21 is directly discharged into the evaporating pan 221 on the top floor; There are water holes for introducing water into the lower layer.

[0032] Under the control of the solenoid valve connected to the drain pipeline 11 at the bottom of the outer tub 1, the water storage tank 21 only collects the waste water discharged when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com