Plate back press forming method utilizing displacement control mode

A technology of displacement control and pressure forming, which is applied in the field of plate forming, can solve the problems of large deformation and complex shape, and achieve the effect of large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

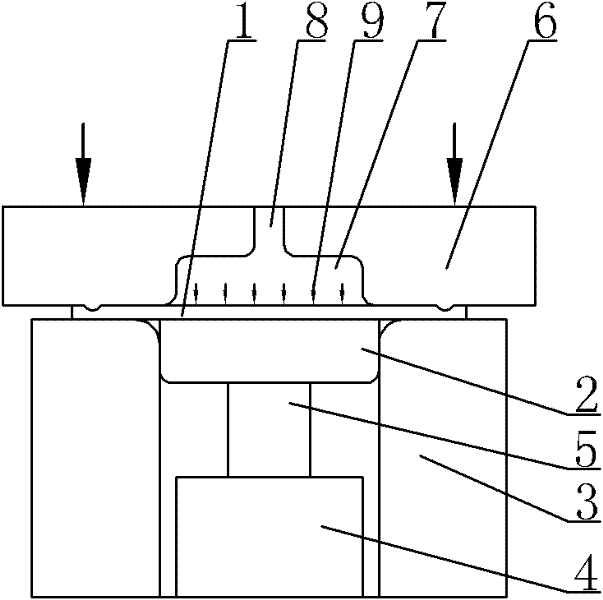

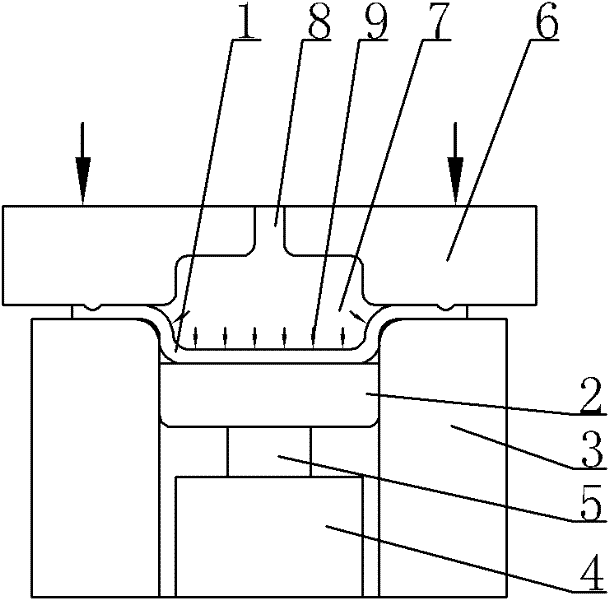

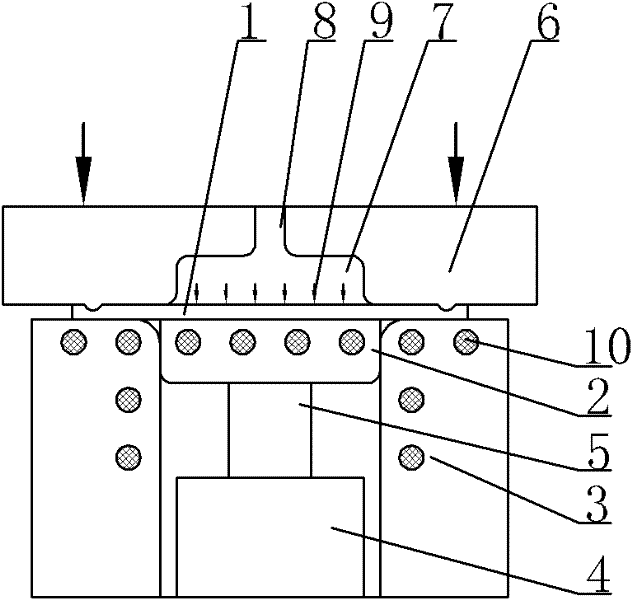

[0013] Specific implementation mode one: combine Figure 1 to Figure 8 To illustrate this embodiment, the specific steps of a method for pressurizing the back of a plate using a displacement control method described in this embodiment are as follows:

[0014] Step 1, placing the slab 1 to be formed on the die base 2, adjusting the position of the plunger rod 5 of the hydraulic cylinder 4, so that the upper surface of the die 3 contacts the lower surface of the slab 1 to be formed;

[0015] Step 2, the pressing plate 6 moves downward to press the slab 1 to be formed on the upper surface of the die holder 2, and the lower surface of the pressing plate 6 and the upper surface of the slab 1 to be formed form a closed cavity 7;

[0016] Step 3: Inject the high-pressure fluid medium 9 into the cavity 7 through the through hole 8 opened above the pressure plate 6;

[0017] Step 4, by controlling the plunger rod 5 of the hydraulic cylinder 4 to move down, the die 3 and the slab to be...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 , figure 2 , Figure 5 with Image 6 To illustrate this embodiment, the high-pressure fluid medium 9 in Step 3 of a method for pressurizing the backside of a plate using a displacement control method described in this embodiment is a liquid high-pressure fluid medium 9 of 1-200Mpa. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 , figure 2 , Figure 5 with Image 6 To illustrate this embodiment, the high-pressure fluid medium 9 in Step 3 of a method for pressurizing the backside of a plate using a displacement control method described in this embodiment is a gaseous high-pressure fluid medium 9 of 1-100 Mpa. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com